Sponsored by Vitrek, LLCReviewed by Maria OsipovaSep 18 2025

Critical electrical performance criteria must be accurately defined and measured to ensure the dependability and safety of high-voltage equipment and connections. Safety risks are severe in applications using tens of thousands of volts, as are the demands placed on the test equipment needed to assess the equipment and connections.

Image Credit: Vitrek, LLC

Proper calibration of test instruments is crucial for meeting the stringent performance requirements of many equipment types.

Calibration results must frequently meet national and international standards, and calibration measures are usually performed by recognized laboratories with traceability to national standards, such as those maintained by the National Institute of Standards and Technology (NIST).

This article discusses the significance of high-voltage test equipment calibration and the rigorous steps required to maintain measurement accuracy.

High-Voltage Measurement Techniques

Each of the many techniques for high-voltage measurement has distinct advantages and must be calibrated using different techniques.

- Step-Down Transformers: Reduce excessive voltage to reasonable levels for measurements.

- Capacitive and Resistive Voltage Dividers: Distribute voltage proportionally.

- Series Resistance (Microampere Measurement): Measures current through a high resistance connected to the voltage source.

- Analog Style Measurement Devices:

- Sphere Gaps measure voltage by measuring the breakdown voltage of two spheres.

- Electrostatic measurement determines the electrostatic force between two plates.

Figure 1. Many types of equipment are used for high-voltage measurement. Image Credit: Vitrek, LLC

Why Measure High Voltage?

Measuring high voltage becomes more critical as technology improves. High-voltage systems lower current-carrying requirements while minimizing energy loss. Voltage settings also significantly impact system performance.

This means the voltage sources must be precise and dependable to meet system requirements. Monitoring measures must also be in place to guarantee that the systems operate consistently from start to finish and year after year.

High-Voltage Applications by Industry

High voltage, defined here as 1 kV to 150 kV (AC or DC), is employed in several fields, including:

- Analytical Instruments: Mass spectrometers and photomultiplier tubes.

- Defense and Aerospace: Radar systems, CRT displays, and flight simulators.

- Homeland Security: Baggage screening and bomb detection equipment.

- Inspection and Non-Destructive Testing: Systems that ensure material and structural integrity.

- Manufacturing Processes: Electron beam welding and electrostatic coating applications.

- Medical and Biotechnology: X-rays and radiographic equipment.

- Research Laboratories: Products include detectors, accelerators, and large-scale analyzers.

- Semiconductor Equipment: Required for ion implantation and sputtering procedures.

- High Voltage Power Supplies: Essential for industrial applications.

- RF Generators and Matching Networks: Used in telecommunications and television.

- Power Distribution: Crucial for detecting corona and testing cable insulation in electrical cables and harnesses, whether in utility networks, manufacturing plants, or campuses.

Accurate high-voltage measurement is required in these subsystems to ensure operating efficiency and safety. Devices that need high voltage readings include:

- Hipot Testers: Ensure the integrity of electrical insulation.

- X-Ray Power Supplies: Validate performance for medical and industrial imaging.

- Ion Implantation Systems: Regulate electrical systems for precise particle acceleration.

- Energy Transmission Sub-Stations: High voltages in power grids enhance efficiency and reduce losses.

Safety Considerations

- Establishing appropriate earth ground conductivity prevents dangerous ground loops.

- Ensuring sufficient clearance avoids unintended flashovers.

- Proper barrier positioning protects people from high-voltage areas under all conditions.

- Means of discharging stored energy in voltage systems ensures safe adjustments.

- Following Manufacturer Guidelines: Adherence to recommended practices minimizes risk.

High-Voltage Test Equipment Calibration

Calibration Standards and Accreditation

ISO/IEC 17025:2017 specifies the general requirements for calibration and test laboratories to be considered technically competent to conduct calibrations. Standards such as ANSI/NCSL Z540-1-1994 are accepted in the industry for setting measurement uncertainty criteria.

Accredited labs must undertake periodical exams to keep their certifications. These ensure that their procedures, environment, and personnel reach the highest competency levels.

Ensuring Measurement Uncertainty

When calibrating high-voltage test equipment, it is critical to account for all sources of measurement uncertainty, which include:

- Equipment Accuracy and Precision: Every measuring instrument has a defined accuracy, which is frequently represented as a percentage of the reading or a fixed value. Precision, on the other hand, refers to an instrument's capacity to deliver consistent readings over multiple measurements. Regular calibration guarantees the instrument's accuracy and precision remain within the prescribed tolerances.

- Signal Type and Frequency: Signal type (AC or DC) and frequency can impact high-voltage readings. AC signals, particularly those at high frequencies, might contribute additional inaccuracies due to reactive components in the measurement system. The measurement must consider this responsiveness to retain its accuracy.

- Calibration Procedures: Compare the instrument's measurements to a recognized standard and make appropriate modifications. To reduce extraneous impacts, this process must take place in controlled surroundings. Calibration periods vary according to the instrument's use and the importance of its measurements. Manufacturers usually prescribe optimal intervals.

- Environmental Effects: Environmental factors, including temperature, humidity, and altitude, can dramatically affect measurement accuracy. Temperature variations, for example, might cause material expansion or contraction, changing component physical dimensions and, as a result, measurement. Humidity can affect the conductivity and dielectric properties of insulating materials, whilst altitude variations can modify air density, influencing high-voltage discharge characteristics.

- Cables and Connections: High-quality cables and secure connections are required for precise high-voltage tests. Poor connections may create resistance, resulting in voltage drops and erroneous measurements. Furthermore, cables should be selected based on their voltage rating and insulation qualities to avoid leakage currents and ensure safety.

- External Influences: Uncontrolled variables such as EMI and corona discharges can cause large inaccuracies in high-voltage measurements. EMI can be reduced by employing insulated wires and ensuring adequate grounding. Corona discharge, induced by ionization of the air around conductors, should be minimized by utilizing smooth, rounded connections and eliminating sharp points that can concentrate the electric field.

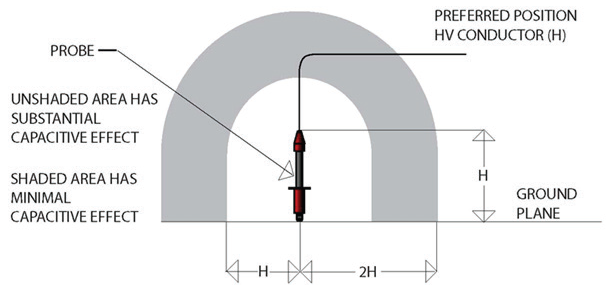

Corona and Connections

Corona discharge is a typical cause of errors in high-voltage measurements. It happens when an electrical discharge ionizes the surrounding air, usually at sharp points or at air gaps in insulation. To minimize corona:

- Smooth connecting points to prevent discharge

- Use larger diameter wires to reduce electric field strength near conductors.

- Ensure adequate isolation between high-voltage components.

- Use continuous insulation with no gaps to prevent internal discharges.

Figure 2. What Not To Do — Loose Wire Ends, Different Wire Thicknesses, Sharp Wire Bend. Image Credit: Vitrek, LLC

Fields and Interference

High voltages create large electrical fields that can be affected by adjacent objects, including the operator. External electrical interference from radio stations and military facilities can potentially affect measurements. To reduce these effects:

- Keep measurement setups away from potential sources of interference.

- Employ proper shielding techniques to protect against external fields.

- Avoid movement of objects or personnel near the measurement area during testing.

Figure 4. Diagram Showing Influence of External Fields on High Voltage Probe. Image Credit: Vitrek, LLC

Total System Uncertainty

Total system uncertainty refers to all possible causes of inaccuracy in a measurement setting. This includes:

- Device and Divider Errors: Each component in the measurement system introduces its own level of error.

- Operator Bias and Location Effects: The experience of the operator and the measurement environment can affect results.

- Software Influence: Ensure the software used for data collection and analysis is accurate and reliable.

High-Voltage Test Equipment Needs to Fit the Application

Devices used in standards and calibration labs worldwide can offer simultaneous readings of AC/DC voltage, frequency, peak-to-peak, and crest factor.

The Vitrek 4700, for example, can measure up to 10 kV directly and up to 150 kV using their proprietary Smart Probes. It also includes a chart mode for graphically documenting high voltage drift, ramp time, overshoot, and sag – critical characteristics that can indicate failure.

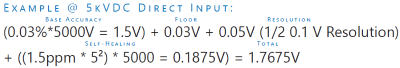

Accuracy calculations for equipment such as the Vitrek 4700 remain valid for one year after calibration.

The accuracy specifications include measurement errors in the standards and techniques used by the manufacturer to calibrate the tester and probes. The measurement accuracy specification includes base accuracy, floor, resolution, and high voltage self-heating parameters.

Direct measurements do not require any additional accuracy computations at the terminal.

Performance and Automation

The best available test equipment employs Digital Signal Processing (DSP) technology, which can give superior AC and DC voltage accuracy, stability, and resolution. Signal averaging, for example, is a simple DSP technique that can increase measurement precision and stability.

Ideally, the device should support test automation by including Ethernet and high-speed serial connection ports, allowing it to be fully configurable for specific testing requirements.

Some equipment, such as the Vitrek 4700, includes a USB printer port for recording measurements and printing hardcopy high voltage graphs. This meter and its SmartProbes come with an ISO17025 calibration certificate, which guarantees accuracy and traceability.

The Role of Accredited Laboratories

Accredited laboratories play an important role in preserving measurement accuracy. These laboratories offer traceability to national and international standards, providing consistent and reliable calibration.

For example, the American Association for Laboratory Accreditation (A2LA) has accredited Vitrek's calibration lab to ISO 17025:2017 and ANSI/NCSL Z540-1-1994 standards. This ensures that all measurements are traceable back to the International System of Units (SI) through national metrology institutes such as NIST and NRC.

Conclusion

Calibration of high-voltage test equipment is not only a technical need, but also a critical component of safety and reliability. By following stringent standards and rigorously accounting for all causes of measurement uncertainty, it can be ensured that high-voltage systems perform precisely and reliably.

Accredited laboratories are essential in maintaining high standards because they provide the expertise and traceability required. As technology advances, the need of precise high-voltage measurements will only increase, making it critical for enterprises to invest in adequate calibration methods.

Understanding high-voltage measurement means protecting both the equipment and the people who rely on it, resulting in a safer and more efficient future for everyone.

Acknowledgments

Produced from materials originally authored by Bryan Withers, Vice-President, Engineering – Vitrek, LLC.

This information has been sourced, reviewed and adapted from materials provided by Vitrek, LLC.

For more information on this source, please visit Vitrek, LLC.