Drones have transformed aerial operations that once required costly methods, such as helicopter use, or were simply not feasible.

Image Credit: SizeSquares/Shuttertstock.com

Today, they are deployed across a wide range of applications, from real estate photography and traffic monitoring to sports coverage and military operations. Larger drones are even being trialed for package delivery by companies like Amazon.

In modern warfare, drones have become indispensable, serving roles from surveillance to functioning as either simple, low-cost weapon carriers or highly advanced unmanned aerial vehicles (UAVs).

However, from a design perspective, drones face numerous challenges and competing requirements. They house complex, sensitive electronics that must operate reliably in harsh environments, while also maximizing endurance between battery recharges.

A Challenging Electronic Design Environment

The focus of this article is on the thermal management and physical protection of batteries and electronics within drones, but to form a complete picture it is also important to consider other aspects of their electronic design and operation.

Addressing electronic challenges is critical to ensuring both functionality and safety. Efficient power management schemes are required to distribute electricity to energy-hungry components like motors as well as lower-demand devices such as sensors, without excessively compromising battery life.

The battery itself must strike a careful balance between capacity and weight: it needs to provide sufficient power for extended flight time while keeping the drone light enough to avoid unnecessary energy consumption. Energy density is key here, allowing batteries to remain compact yet powerful.

Looking ahead, the development of next-generation battery technologies and alternatives to lithium-ion will be pivotal in improving power density, flight time, and range, ultimately expanding the number and variety of drone applications.

In what is often a hostile electrical environment, protecting circuitry from overcurrent, overvoltage, and short circuits is essential to prevent component damage. Since drones frequently operate in areas with high or unpredictable interference, minimizing susceptibility to electromagnetic interference (EMI) is equally important to avoid disruptions to electronics and communication systems.

Maintaining signal integrity is also critical to ensuring precise control and reliable data transmission. At the device level, the ongoing trend toward integrating smaller electronic components supports reductions in both size and weight while preserving functionality.

Greater integration also enhances reliability by reducing the number of exposed interconnects external to components. Finally, because system reliability is paramount, robust redundancy measures must be implemented for critical components to provide safeguards and backups against in-flight failures.

Physical Protection

Drone battery pack cells must be protected against vibration and environmental factors such as moisture ingress, and this has to be achieved with lightweight, repeatable solutions.

Traditional potting compounds can provide protection, but they are heavy and difficult to integrate into production. In contrast, cell carrier materials that are easier to manufacture offer a cleaner, more practical alternative.

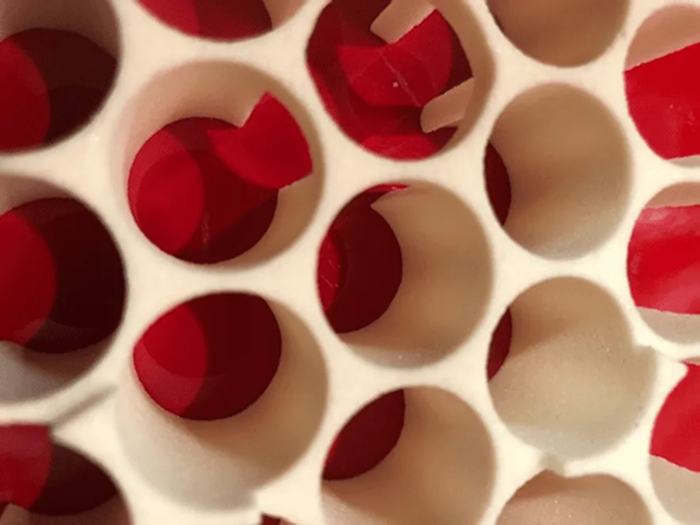

Specialist foams are increasingly being used as cell carriers, giving designers an effective tool for battery pack construction. For example, the EV-UniFoam range from Universal Science can perform multiple roles. Its primary function is to act as a carrier, holding and positioning multiple cells firmly in place within the pack to prevent movement.

Beyond this, custom foam carriers - produced without the need for tooling in the case of Universal Science - help absorb vibration. This is critical, as battery packs are continuously subjected to shocks and vibration during a drone’s service life, which can cause damage to interconnects and surrounding electronics.

Other important properties for drone applications include flame retardancy/self-extinguishing behavior and low moisture absorption, both of which further enhance the safety and reliability of the battery pack.

Figure. Structural vibration damping foams provide a clean, lightweight and repeatable alternative to potting compounds for drone battery packs. Image Credit: Materials Direct

Drone Thermal Management

The batteries, motors, and other power electronics in drones all generate heat that must be managed within safe limits to ensure reliable operation.

Active cooling components, such as fans, can provide strong thermal performance, but they are heavy, drain valuable battery power, and are generally less reliable than passive cooling methods that rely on heat-conducting materials. Heatsinks are one such passive option, but their weight usually makes them impractical for drones.

A more effective approach is to couple heat-generating elements directly to the drone’s chassis or body - when it incorporates metal elements - so it functions as a built-in heat spreader and dissipator without the need for additional components.

Because drones must often operate in all weather conditions, partially open or vented enclosures, which would improve cooling, are not a viable option due to the risk of moisture ingress.

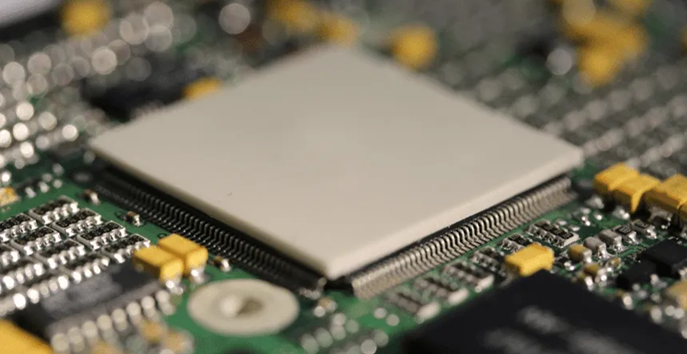

Instead, thermal management is best achieved by “connecting” heat-generating components to the chassis using thermal interface pads or gap fillers. These materials combine high thermal conductivity with vibration-damping properties, offering a proven solution that has been applied successfully across many industries, including drones.

Figure. Gap filler materials used in drones can help dissipate heat to the chassis or enclosure. Image Credit: Materials Direct

Lithium-ion batteries, commonly used as drone power sources, need to operate between approximately 5 °C and 50 °C. Staying within this range avoids premature degradation and the more serious concern of thermal runaway.

A high-performing foam carrier, such as EV-UniFoam, that surrounds and holds individual cells within a pack also contributes to the general heat management and stability of a drone battery pack. Its close cell structure safeguards the batteries against harsh outside temperatures and helps keep the pack within safe limits.

How Materials Direct Can Help

Materials Direct specializes in delivering cutting-edge materials that can substantially improve drone designs. Its portfolio of thermal interface solutions, including high-performance gap fillers and thermal pads, facilitates heat dissipation from sensitive components including batteries and motors, eliminating the need for heavy, power-intensive fans.

In addition, the company’s EV-UniFoam cell carriers provide lightweight, repeatable solutions to safeguard battery packs against vibration, moisture, and harsh temperatures, ensuring consistent performance under extreme conditions.

By providing tooling-free, customized fabrication, Materials Direct provides design flexibility, enabling streamlined fabrication and reduced expenses.

Whether solutions are needed for thermal management, structural protection, or electromagnetic shielding, Materials Direct is well-positioned to help address the technical challenges faced by drones, guaranteeing efficient and reliable operation in the field.

Summary

Designing drones that are reliable, robust, and capable of meeting their mission requirements requires a careful balance between physical protection and thermal management of the battery pack and electronics - all without creating a design that is excessively heavy.

Lightweight cell carrier materials provide a strong alternative to heavy potting compounds, protecting battery packs and ensuring a stable operating environment. Likewise, thermal interface materials offer an efficient way to manage heat in electronic components, reducing or even eliminating the need for active cooling solutions like fans.

Acknowledgments

Produced from materials originally authored by James Stratford, Technical Director, Universal Science and Materials Direct.

This information has been sourced, reviewed and adapted from materials provided by Materials Direct.

For more information on this source, please visit Materials Direct .