Advanced Environmental Laboratories (AEL), located in Jacksonville, FL, was established in 1994 and is now Florida's largest laboratory network. The network is NELAC/TNI and DOD certified and offers full-service conventional and PFAS analyses utilizing EPA methods 537.1, 533, and 1633A.

Challenge

AEL performs PFAS testing for soil and biosolids using EPA Method 1633A. Each batch of 20 samples typically takes around three hours to extract, creating strain on resources and making fast turnaround increasingly difficult as customer demands increase.

Solution

Milestone's ETHOS X with XTR-44 has provided AEL with a solution to these problems. As an early adopter of the system, AEL can now perform efficient extractions in a fraction of the time while meeting EPA 1633A quality assurance (QA).

Background

AEL is ranked among the top 10 environmental laboratories in the US. It operates eight strategically positioned TNI/NELAP-certified laboratories across the state, providing unrivaled assistance at the state level and nationwide, including the Caribbean.

With a 30-year environmental service history, AEL continues to expand and develop sustainability initiatives. The lab assists over 1000 clients annually and contributes to over 50,000 projects spanning various industries, from local municipalities to federal projects at DOD military posts and EPA Superfund sites.

AEL has invested in constructing a facility focusing on PFAS analysis to address emerging pollutants. With an emphasis on efficiency and accuracy, the lab’s goal has been to streamline PFAS sample processing to deliver industry-leading turnaround time for clients.

Ethos X PFAS Microwave Technology

Milestone's ETHOS X with XTR-44 position rotor has enabled AEL to process 44 samples and perform quality control in as little as 20 minutes via microwave extraction.

By operating at higher temperatures, using disposable polypropylene vials, and removing unnecessary handling steps, AEL achieves faster processing and reduces the risks associated with traditional shaker table extractions.

This approach enhances safety whilst yielding highly reproducible results. The XTR-44 rotor actively stirs each vial using PFAS-free rare earth magnets. These advantages motivated AEL's adoption of this technology.

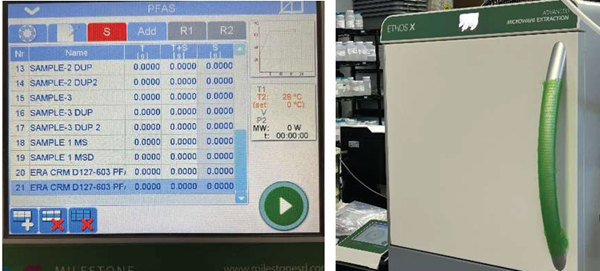

ETHOS X microwave extraction system and its user-friendly interface. Image Credit: Milestone S.r.l.

The capabilities of the ETHOS X PFAS extraction solution offer us the ability to process more samples and increase capacity to allow for acceptance of rush work. This solution provides AEL with predictable turnaround times in this very competitive landscape.

Brandon Beck, Vice President – Operations

The Ethos X With XTR-44 Rotor – Data

The flexibility given by EPA 1633A encouraged AEL to adopt the microwave extraction technique. In initial demonstrations, comparison data and recoveries exceeded EPA 1633A standards, with improved recoveries of some of the more problematic and heavier PFAS species in real-world samples.

Using the XTR-44 high-throughput rotor, AEL was able to extract up to 34 samples and perform batch quality control in a single microwave run, using half the LC/MS grade methanol per sample and substantially less labor and time.

Shaun West, PFAS Lab Manager. Image Credit: Milestone S.r.l.

To further enhance capacity, AEL has expanded its extraction instrumentation capabilities by incorporating Milestone's ETHOS X fastEX-24 extraction equipment and ETHOS UP digestion systems into several of its laboratories.

These expenditures have made the sample preparation process more efficient than alternative approaches, increasing productivity, improving employee safety, and saving on labor and solvents. These benefits have motivated the device’s successful implementation.

We have had a unique opportunity to partner with Milestone to provide proof of concept and initial demonstration of capability. The data showed improved recoveries and comparability and meets the requirements of EPA 1633A. In addition, the microwave approach opens AEL up for new matrix applications such as food, feeds and commercial products to set AEL apart in the PFAS market.

Shaun West, LC Department Manager

Future Plans

AEL continues to ensure that it meets clients' rigorous needs. Workflow improvement is a consistent effort, and AEL’s continued engagement with Milestone demonstrates the benefits of overall workflow improvements.

AEL’s new PFAS lab on the Jacksonville, FL campus. Image Credit: Milestone S.r.l.

About Milestone

Milestone has over 50 patents and more than 35,000 instruments installed in laboratories worldwide, making it the global leader in metals prep technology for the past 35 years.

Committed to offering safe, dependable, and versatile platforms to help your lab run more efficiently, customers worldwide rely on Milestone for metal digestion, organic extractions, mercury analysis, and clean chemical processing.

This information has been sourced, reviewed and adapted from materials provided by Milestone S.r.l.

For more information on this source, please visit Milestone S.r.l.