In this interview, AZoMaterials speaks with Dr. Mark Coleman, EBSD Product Manager at Oxford Instruments NanoAnalysis, about how the MapSweeper software enhances electron backscatter diffraction (EBSD) workflows. Here, he provides an overview of EBSD fundamentals, the limitations of traditional Hough indexing, and how dynamic template matching within MapSweeper accelerates phase identification and increases precision. Dr. Coleman also shares compelling application examples that demonstrate the advantages of MapSweeper in complex materials systems.

Can you please introduce yourself and your role at Oxford Instruments?

My name is Dr. Mark Coleman, and I’m the EBSD Product Manager at Oxford Instruments NanoAnalysis. I’m based in High Wycombe in the UK. My role involves developing and supporting EBSD technologies, particularly advancing our software capabilities, such as MapSweeper, to provide better solutions for materials characterization.

For readers unfamiliar with the technique, can you briefly explain what EBSD is and what it’s used for?

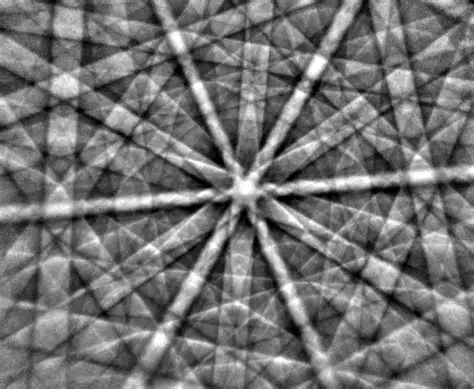

EBSD stands for Electron Backscatter Diffraction. It’s an SEM-based technique that allows us to determine crystallographic information from materials. By tilting the sample and capturing diffraction patterns, known as EBSPs (Electron Backscatter Patterns), we can analyze crystal orientations, phases, and microstructures. EBSD is crucial for understanding grain boundaries, phase distributions, and texture, all of which influence material properties.

What are the main limitations of traditional Hough indexing in EBSD?

Hough indexing is computationally fast and generally reliable, but it struggles in several areas. It lacks the angular resolution to differentiate between phases with very similar structures, like ferrite and martensite in steels. It also fails in regions with poor-quality EBSPs, such as highly strained or deformed materials, and in situations involving pseudosymmetry, where one pattern may yield multiple plausible solutions.

How does MapSweeper software overcome these limitations?

MapSweeper uses dynamic template matching instead of the Hough transform. It compares experimental EBSPs with simulated patterns based on known phases and beam conditions. This technique achieves angular precision better than 0.01 degrees – an order of magnitude improvement. It enhances hit rates in poor quality data, repairs indexing errors, and enables accurate phase identification even in challenging microstructures.

Could you explain how pattern matching works in MapSweeper?

Certainly. The are two different approaches to pattern matching in MapSweeper. In both cases, we acquire and store EBSPs. In the first approach, MapSweeper then creates simulated patterns to correlate with the experimental EBSPs. It incrementally changes the simulated pattern until a best match is obtained using a cross-correlation factor. This approach is targeted at the EBSPs that Hough indexing cannot solve, such as highly deformed areas of a sample. Since the generation of simulated patterns is dynamic it avoids the slow speeds of traditional dictionary indexing while maintaining high accuracy.

You mentioned there was a second approach to pattern matching?

Yes. The second approach uses the Hough indexing results to generate an initial orientation estimate. Since the Hough indexing is already a very good orientation estimate, only nearby orientations need to be simulated, and the best solution is identified much more quickly than using dynamic template indexing alone. Hough indexing typically solves over 80% of patterns, we should avoid discarding that information. Using it as a starting point, datasets can be analyzed via pattern matching in minutes, not hours. This hybrid indexing method is what allows quick evaluation of other problems like discrimination of phases with common crystal structures, pseudosymmetry, and quantifying elastic strain by varying the strain tensor in the simulation.

What types of materials or scenarios particularly benefit from using MapSweeper?

MapSweeper is especially powerful in multi-phase systems and heavily deformed materials. For example, when analyzing steels with ferrite and martensite, Hough indexing can’t resolve the subtle tetragonality that distinguishes these phases, but MapSweeper can. It also excels in Transmission Kikuchi Diffraction (TKD), where variable sample thickness causes a drop in pattern quality. MapSweeper helps recover high indexing performance in those cases.

Image Credits: Oxford Instruments

You mentioned dynamic template matching improves speed – how fast is MapSweeper compared to other methods?

Dynamic template matching enables MapSweeper to process between 100 and 1,000 patterns per second, depending on system configuration. This is a substantial improvement over dictionary indexing, which is often limited to a few patterns per second. That means users can apply high-precision pattern matching to full maps without excessive processing time.

What is the typical workflow for someone using MapSweeper?

The process starts by simulating master patterns for each expected phase at the specific beam conditions. You then run your EBSD map and store selected EBSPs. Using the initial Hough-indexed data, MapSweeper refines orientations via dynamic template matching. Finally, it outputs a corrected orientation or phase map that reflects significantly improved precision and accuracy.

Can you share any real-world application examples that highlight the software's capabilities?

One example involved distinguishing ferrite from martensite in dual-phase steel. The tetragonal distortion of martensite is so subtle that it’s missed by Hough indexing. MapSweeper was able to clearly resolve the phases. Another case involved the TKD of nanocrystalline materials, where pattern quality was inconsistent due to variations in sample thickness. MapSweeper recovered high indexing rates across the full sample area.

How should new users get started with MapSweeper, and what should they keep in mind?

For new users, it’s important to understand that MapSweeper is an add-on to AZtecCrystal. You’ll need to generate high-quality simulated patterns matched to your beam settings. A library of simulations can be created to avoid the need for generating simulations for each EBSD map. It’s also vital to calibrate accurately, especially in multi-phase materials. However, once set up, it’s a straightforward tool that can significantly enhance EBSD data quality and interpretation, even for users with limited experience in pattern matching.

About Dr. Mark Coleman

Mark Coleman is the EBSD product manager at Oxford Instruments NanoAnalysis. He holds a PhD from Swansea University, focusing on using EBSD to study grain boundary engineering mechanisms. As a Senior Lecturer, he was also the Program Director for the Materials Science and Engineering department and has worked heavily with industry on using SEM based techniques for materials failure analysis. More recently, he has worked on integrating EBSD with in-situ heating and micromechanical testing.

This information has been sourced, reviewed, and adapted from materials provided by Oxford Instruments.

For more information on this source, please visit Oxford Instruments.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.