In this interview, AZoMaterials speaks with Dr. Mark Coleman, EBSD Product Manager at Oxford Instruments, about the new strain analysis tool in AZtecCrystal 3.3. Dr. Coleman explains how recent advances in pattern matching and angular precision have enabled the quantification of strain at the sub-grain level, revolutionizing EBSD-based deformation studies. The discussion also touches on how this release improves the software’s capabilities for high-resolution strain mapping, phase discrimination, and challenging applications such as TKD.

Can you please introduce yourself and your role at Oxford Instruments?

My name is Dr. Mark Coleman, and I’m the EBSD Product Manager at Oxford Instruments, based in High Wycombe. I lead the development of our EBSD software and hardware products, working closely with our customers and application scientists to deliver advanced characterization tools.

In this role, I’ve been heavily involved in the development of AZtecCrystal, particularly its latest version, 3.3, which introduces a powerful new strain analysis tool.

What is electron backscatter diffraction (EBSD), and why is it important in materials characterization?

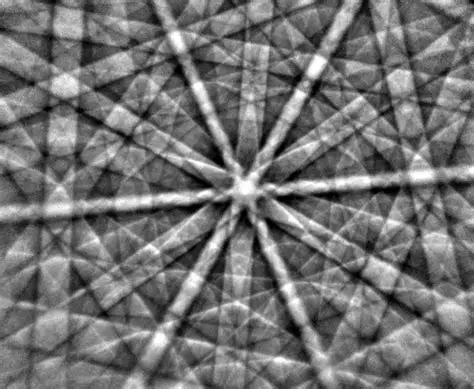

EBSD is a technique that provides crystallographic information from a sample using a scanning electron microscope (SEM). When the SEM's electron beam interacts with a tilted crystalline sample, backscattered electrons form diffraction patterns on a detector.

These patterns, known as EBSPs (Electron Backscatter Patterns), are then used to determine the crystal orientation and phase distribution. EBSD is particularly powerful in polycrystalline materials, where grain orientation, size, and internal strain have a significant influence on material properties such as strength and ductility.

What motivated the development of the new strain analysis tool in AZtecCrystal 3.3?

There’s been a growing need in materials science to quantify deformation with higher precision. Traditional misorientation-based metrics, such as Kernel Average Misorientation (KAM), Grain Reference Orientation Deviation (GROD), or Grain Orientation Spread (GOS), provide only indirect indicators of strain.

To directly measure lattice strain, we needed a tool that could quantify subtle distortions in diffraction patterns with extremely high angular resolution, something the conventional Hough-based indexing couldn’t offer. That gap led us to develop a new tool leveraging pattern matching, now integrated into AZtecCrystal 3.3.

How does AZtecCrystal 3.3 achieve the angular precision required for reliable strain measurements?

The key advancement is the use of pattern matching via MapSweeper’s refinement mode. While Hough-based indexing typically achieves angular precision of around 0.5 to 0.1 degrees, pattern matching reduces this to better than 0.01 degrees.

This is achieved through iterative comparison of simulated Kikuchi patterns against experimental ones, refining the match until the cross-correlation coefficient is maximized. This precision is essential to resolve the small lattice rotations and strains that occur during plastic deformation or thermal processing.

Can you describe how the refinement process works within MapSweeper?

Refinement starts with a stored diffraction pattern and an initial solution obtained through standard, Hough indexing. Using this as a baseline, the software introduces hundreds of minor variations in the simulated pattern, adjusting parameters such as orientation and strain tensor components.

For each iteration, it calculates the correlation between the simulated and real patterns. This iterative fitting process continues until it finds the best match, enabling the system to determine more accurate orientation and the local strain tensor for that point.

Image Credits: Oxford Instruments

In what types of materials or research scenarios is this new strain analysis most useful?

This tool is particularly useful in materials undergoing deformation, recrystallization, or recovery – situations where lattice strain plays a critical role. It’s invaluable in process optimization for any material that has undergone thermo-mechanical treatments, such as forging, annealing, or machining. One key advantage of Strain Analysis in MapSweeper is that it can be measured using binned, 8-bit EBSPs, which means customers don't need to measure, save, and re-process high resolution EBSPs.

How does this tool compare with previous methods like KAM or GROD for strain-related analysis?

KAM and GROD maps are based on misorientation between neighboring points and reflect local crystal lattice rotations rather than true strain. They're excellent for visualizing deformation gradients but lack absolute quantitative strain information. In contrast, the new strain analysis tool calculates the strain tensor directly from Kikuchi pattern distortions.

This provides a more physically meaningful and spatially resolved measurement of elastic strain within grains, enabling researchers to more accurately link microstructure to mechanical performance.

Can this approach help distinguish between similar phases or highly deformed materials?

Yes, one of the advantages of the pattern matching is its ability to index poor-quality EBSPs and differentiate between phases with very similar unit cells. The enhanced angular resolution can distinguish very subtle differences in patterns for phases with the same, or very similar crystal structures (e.g. ferrite and martensite). It also allows for feint or poorly resolved patterns, common to deformed materials or techniques like Transmission Kikuchi Diffraction (TKD), to be solved.

Beyond strain analysis, what other improvements are included in AZtecCrystal 3.3?

Version 3.3 introduces several updates beyond strain mapping. We've improved the user interface and processing speed in MapSweeper, making large dataset processing much faster. The particle analysis tools have also been upgraded, with new metrics and automation features. Overall, the update enhances usability, batch processing efficiency, and high-throughput workflows for both academic and industrial users.

What’s next for AZtecCrystal and strain analysis development?

We’re continually working to increase both performance and accessibility. One area of focus is further improving the simulation models for diffraction patterns, making them more accurate and computationally efficient. We're also exploring automation of strain analysis in complex datasets and batch processing pipelines.

As interest grows in 3D strain mapping and correlative techniques like HR-EBSD and TKD, we aim to ensure that AZtecCrystal remains at the forefront of microstructural characterization.

About Dr. Mark Coleman

Mark Coleman is the EBSD product manager at Oxford Instruments NanoAnalysis. He holds a PhD from Swansea University, where he focused on using EBSD to study grain boundary engineering mechanisms. As a Senior Lecturer, he was also the Program Director for the Materials Science and Engineering department and has worked closely with industry on using SEM-based techniques for materials failure analysis. More recently, he has worked on integrating EBSD with in-situ heating and micromechanical testing.

This information has been sourced, reviewed, and adapted from materials provided by Oxford Instruments America.

For more information on this source, please visit Oxford Instruments America.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.