How IR Temperature Measurement Enhances Battery Monitoring

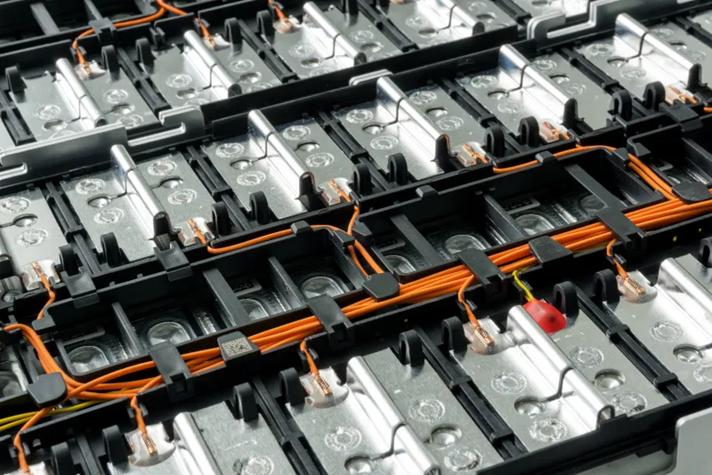

Infrared (IR) temperature measurement plays a key role in ensuring the safety and optimal performance of batteries across a wide range of applications.

Accurate temperature control is particularly essential in the battery industry, especially during the processes of coating battery electrodes and sealing batteries. Precise IR temperature measurement helps maintain optimal conditions throughout these crucial stages, preventing defects and ensuring high-quality battery production.

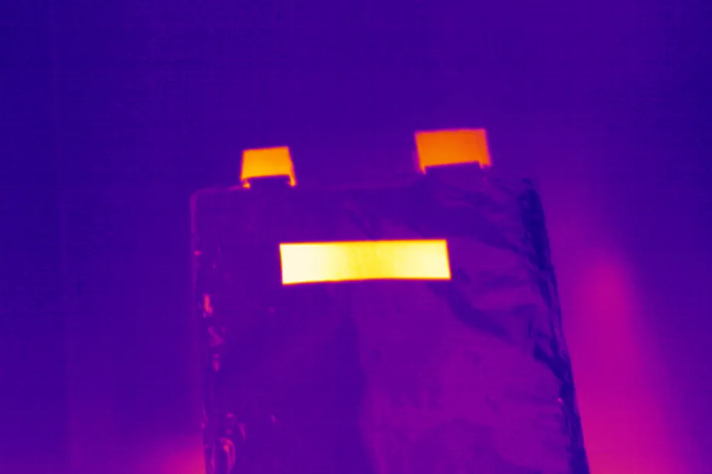

Thermal battery State of Charge (SOC) represents another key area where IR technology is invaluable. By instantly monitoring temperature fluctuations, IR sensors enable an accurate assessment of a battery’s thermal state, which is directly related to its SOC.

This capability supports battery performance optimization, extends its lifespan, and prevents thermal runaway events that could lead to catastrophic failures.

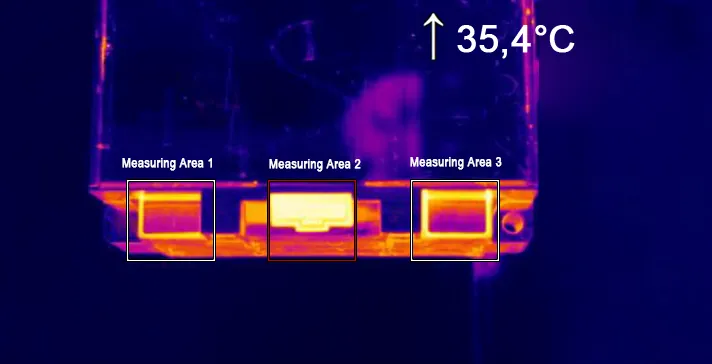

Moreover, battery monitoring using IR cameras and pyrometers allows for early detection of overheating and thermal anomalies. This proactive strategy ensures batteries operate within safe temperature ranges, minimizing the risk of thermal issues.

By integrating IR technology, manufacturers can improve the safety and reliability of battery systems, minimize maintenance expenses, and increase efficiency in battery management.

Overall, IR temperature measurement is required for upholding high standards in battery quality and performance.

Image Credit: Optris GmbH & Co. KG

Challenges of IR Temperature Measurement in Battery Manufacturing and Monitoring

A key challenge in IR temperature measurement is the varying emissivity values of different materials used in battery production, including electrode coatings and sealing compounds. Emissivity affects infrared radiation emission, impacting accuracy.

Without proper calibration for specific emissivity settings, IR sensors may produce incorrect temperature readings, resulting in manufacturing defects and impaired battery performance.

Managing thermal gradients during processes such as electrode coating and sealing presents difficulties. Uneven temperature distribution can create hot or cold spots that may be difficult for IR sensors to detect in large or complex setups. This can result in inconsistent battery quality and performance issues.

Environmental factors such as high humidity, dust, and contaminants can compromise IR measurement accuracy. These elements can distort data through scattering or absorbing infrared radiation. While maintaining clean sensor lenses and optimal sensor placement is challenging, it is crucial for reliable temperature monitoring.

IR sensors may encounter difficulties in accurately measuring temperatures through certain materials or obstructions. In battery manufacturing, the IR sensor’s view can be obstructed by components such as protective casings or internal layers, making accurate temperature readings difficult.

This limitation can impede effective monitoring of critical production stages, such as curing or sealing processes, where temperature control is vital for ensuring both quality and performance of the final battery product.

Image Credit: Optris GmbH & Co. KG

Advantages of IR Non-Contact Temperature Measurement in Battery Manufacturing

IR non-contact temperature measurement provides significant advantages for improving quality in the battery manufacturing sector. Instantaneous monitoring of temperature throughout critical processes, such as battery electrode coating and sealing, ensures that production conditions remain within optimal ranges.

This capability allows for immediate adjustments when temperature deviations occur, helping to prevent defects and uphold high-quality standards.

By accurately evaluating thermal battery State of Charge (SOC), IR technology aids in monitoring the battery’s thermal performance. This accurate measurement facilitates improved control over the battery’s thermal management, enhancing overall efficiency and extending service life. Early detection of thermal anomalies enables proactive interventions, minimizing the likelihood of thermal runaway and ensuring battery safety.

Moreover, integrating IR sensors into battery monitoring systems strengthens quality assurance throughout the manufacturing process. Consistent temperature measurements ensure that each battery cell meets the required criteria, resulting in enhanced product reliability and performance. This proactive method minimizes the risk of expensive recalls while increasing customer satisfaction with dependable, high-quality batteries.

Image Credit: Optris GmbH & Co. KG

Applications and Efficiency Gains from IR Temperature Measurement

Applying IR non-contact temperature measurement in battery manufacturing delivers considerable efficiency improvements. During the battery electrode coating process, IR sensors deliver critical data on temperature uniformity, ensuring even and effective coating application.

This accuracy prevents problems such as uneven coating thickness or inadequate adhesion, both of which can jeopardize battery performance.

In the battery sealing stage, IR technology closely monitors temperature to ensure adequate curing and bonding. Precise temperature control is crucial to prevent sealing defects and maintain battery casing integrity.

IR sensors help sustain optimal conditions, enhancing the durability and dependability of the final product.

In addition, instantaneous thermal data from IR cameras and pyrometers facilitates improved process control and optimization. Analyzing temperature patterns enables early detection of potential issues, allowing manufacturers to adjust processes accordingly.

This technique improves overall manufacturing efficiency, minimizes waste, and increases the yield of high-quality battery cells. Integrating IR technology into battery manufacturing boosts safety, enhances quality, and supports long-term operational efficiency and cost savings.

Image Credit: Optris GmbH & Co. KG

Battery Monitoring Applications

- Slurry and electrode film monitoring - In-line infrared temperature monitoring for electrode sheet and slurry in high-volume battery cell production

- Battery pouch cell sealing - Detection of faulty seal welding via thermal hotspot detection during load tests using infrared imaging

- Early fire detection - Risk mitigation in energy storage using cutting-edge infrared detection systems

- Thermal battery SOC - Precise state of charge monitoring with two-color pyrometers

This information has been sourced, reviewed, and adapted from materials provided by Optris GmbH & Co. KG.

For more information on this source, please visit Optris GmbH & Co. KG.