Infrared Temperature Measurement: A Game-Changer for the Automotive Sector

Infrared (IR) temperature measurement is transforming the automotive sector by delivering high accuracy and efficiency in production processes. In automotive manufacturing, maintaining optimal temperatures plays a crucial role in ensuring component quality and performance, from engine parts to electronic systems.

IR thermometers and cameras provide non-contact temperature measurement, which is crucial for high-temperature applications, including metal casting, heat treatment, and welding.

These cutting-edge instruments deliver instantaneous thermal data, allowing manufacturers to make immediate adjustments and improve quality control. Precise temperature monitoring prevents defects such as warping or thermal stress, which can impair component integrity.

In automotive assembly, IR sensors help control the temperature of critical components, ensuring they satisfy stringent performance criteria. Non-contact temperature measurement also enhances safety and efficiency, minimizing the likelihood of equipment damage and reducing maintenance requirements.

In addition, IR temperature measurement supports energy efficiency through optimization of heating and cooling processes. This reduces operational expenses and supports sustainable production practices.

By integrating IR technology, automotive producers can achieve superior product quality, reduce manufacturing expenses, and improve operational dependability, making it a true game-changer for the industry.

Image Credit: Optris GmbH & Co. KG

Challenges of IR Non-Contact Temperature Measurement in the Automotive Sector

Infrared (IR) non-contact temperature measurement presents several challenges in the automotive sector. One of the most significant is the variation in emissivity. Automotive parts are built from a range of materials, each with distinct emissivity properties. Precise temperature readings require accurate calibration to account for these differences. Incorrect emissivity settings can result in inaccurate readings, which in turn affect quality control and process optimization.

Elevated ambient temperatures and thermal interference from nearby equipment can also influence IR sensor performance. Automotive production environments, including those involving metal forging or high-temperature curing procedures, produce substantial heat that may distort IR measurements. Safeguarding IR devices against excessive heat and calibrating them for ambient conditions is essential to maintain measurement precision.

Surface reflectivity is another challenge. Highly reflective surfaces, common in automotive parts, can distort infrared readings. To mitigate this, advanced IR sensors with adjustable emissivity settings and regular calibration are critical for reliable temperature measurements.

Image Credit: Optris GmbH & Co. KG

Advantages of Infrared Non-Contact Temperature Measurement

Despite these obstacles, IR non-contact temperature measurement provides significant advantages in the automotive sector, especially in energy savings and quality improvement.

A major advantage is energy efficiency. IR sensors deliver accurate temperature data that supports optimization of heating and cooling procedures, minimizing energy use and reducing operational expenses.

For example, in metal casting and heat treatment, precise temperature control reduces unnecessary energy consumption, supporting more sustainable production practices.

Improved quality control is another key advantage. IR cameras and pyrometers provide instantaneous temperature monitoring during critical automotive processes, including welding, painting, and assembly.

This instantaneous data allows for immediate adjustments, preventing defects such as warping, misalignment, or uneven curing. Maintaining optimal temperatures ensures components meet strict quality specifications and perform reliably, reducing the risk of expensive rework or product recalls.

Image Credit: Optris GmbH & Co. KG

Applications and Efficiency Gains

Infrared non-contact temperature measurement delivers significant efficiency improvements across a wide range of automotive production applications. In engine part manufacturing, IR sensors monitor component temperatures during machining and assembly, ensuring they remain within optimal thermal ranges.

This accuracy helps preserve component integrity and enhances overall performance.

During paint curing, IR cameras facilitate uniform heating, ensuring uniform coating quality while reducing energy use. In battery production, precise temperature measurement during assembly and testing prevents overheating, improving safety and extending battery lifespan.

Overall, integrating IR temperature measurement technology into automotive production processes improves operational efficiency, lowers energy expenses, and ensures outstanding product quality. By delivering precise, instantaneous thermal data, IR technology enables process optimization, waste reduction, and improved sustainability, making it an essential instrument in modern automotive manufacturing.

Image Credit: Optris GmbH & Co. KG

Automotive Industry Applications

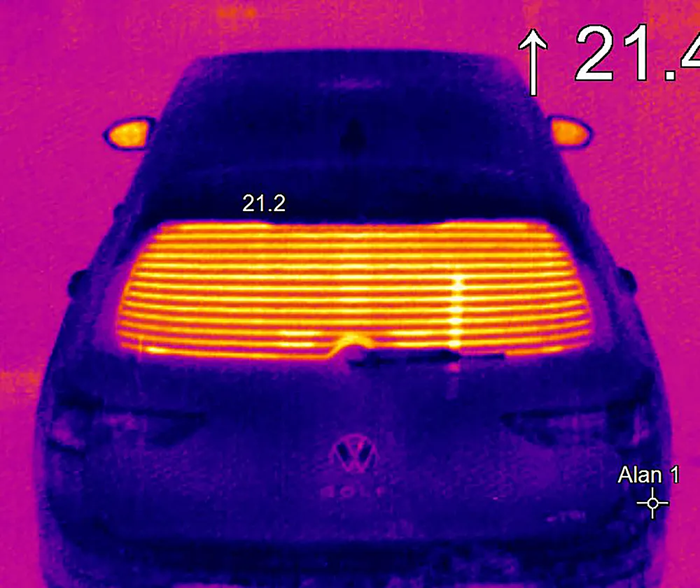

- Car window heater control - Infrared visioning and temperature measurement technology boost manufacturing speed and enhance quality in automotive production

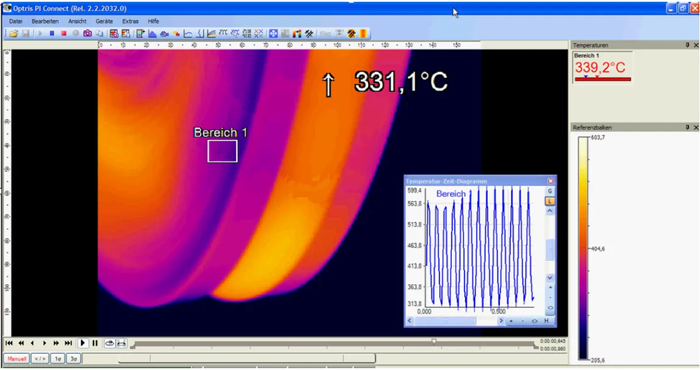

- PAN stabilization - Cutting-edge temperature control methods for PAN oxidation improve carbon fiber quality for automotive production

- Gearbox quality control - Monitoring temperature increases ensures gearbox health and prevents damage in end-of-line inspections

- Fuel tank welding - Uniform heat distribution during plastic fuel tank welding

- Car seat heater testing - Thermal imaging cameras identify and prevent faulty cable connections in car seat heaters

- Brake disc design validation - Thermal imaging improves brake disc testing on test benches for enhanced brake disc design

- Carbon and plastic part bonding - Implementation of Optris Infrared solutions supports automated production in large carbon and plastic component bonding procedures

- Tire curing and vulcanizing procedures - Overcome challenges caused by ambient temperature fluctuations in tire production

- Fiber-reinforced thermoplastics - Pyrometers provide precision temperature control during combined thermoforming and injection molding of thermoplastics

- Addressing thermoforming challenges in automotive exterior component manufacturing - Infrared cameras minimize scrap in thermoforming processes

This information has been sourced, reviewed, and adapted from materials provided by Optris GmbH & Co. KG.

For more information on this source, please visit Optris GmbH & Co. KG.