From Specac LtdReviewed by Maria OsipovaFeb 10 2026

In this interview, Bisirat Araya, Jim Delaney and Jeff D’Agostino share how Specac's collaborative approach to customs transforms scientific intent into tailored spectroscopy solutions.

Jim Delaney

As leader of the applications team at Specac, Jim brings experience from both his scientific background and his eight years at Harrick Scientific, prior to their acquisition by Specac in 2024. Jim talks to us here about his team's approach to customisation and special projects.

What are the first questions you ask to truly understand “the science behind the request”?

When a customer approaches us with a request, the first step is understanding their scientific intent. We start by asking what question the experiment is meant to answer and what success would look like in the data. That frames the discussion around outcomes rather than hardware.

From there, we focus on the sample itself, its physical form, chemistry, and how it interacts with infrared radiation. Whether a sample is a powder, liquid, gas, film, or catalyst bed strongly influences technique and accessory selection. We also ask about operating conditions such as temperature, pressure, reactive or corrosive gases, and safety requirements.

Finally, we consider instrument integration. The spectrometer platform, optical geometry, and experimental workflow all matter.

Often, a simple sketch or photo provides more insight than a formal specification. At this stage, our goal is to listen, clarify assumptions, and ensure the scientific problem is well-defined before discussing solutions or costs.

Often, the winning solution involves a customisation of an existing product. What’s your favorite example of this?

One of the most effective custom solutions we deliver involves adapting existing reaction cells for more demanding chemical or thermal conditions. Rather than designing a new system from scratch, we often modify proven platforms by changing window materials, upgrading seals, or adjusting optical path lengths to match sensitivity requirements.

This approach reduces technical risk, shortens development timelines, and keeps costs under control, essential factors for academic and industrial research groups alike. It also supports long-term usability by delivering solutions that are easier to maintain and replicate.

A recent example involved a university group seeking to perform simultaneous infrared and Raman measurements on the same catalyst sample. By adapting the industry standard Praying Mantis diffuse reflectance accessory and its reaction chamber, we enabled both techniques to probe the same sample volume under identical conditions in a compact, cost-effective setup.

This multimodal approach supports synchronized datasets, which are increasingly crucial for advanced analysis and machine-learning-driven catalyst optimization.

How do you build and iterate a concept with a customer, and what helps avoid over-engineering while keeping designs fit-for-purpose?

The concept summary is central to our custom process. Once feasibility is established, we translate the scientific requirements into a shared proposal that typically includes early sketches, performance trade-offs, and a preliminary budget and lead time.

Iteration is key. Customer feedback often clarifies which requirements are essential and which can be relaxed, for example, adjusting the maximum temperature or path length to simplify the design without compromising the science. In some cases, we also perform quick internal checks to validate assumptions before finalizing the scope.

By discussing trade-offs early and transparently, we keep designs focused on delivering meaningful data rather than unnecessary complexity. The result is a solution that is practical, affordable, and aligned with how the experiment will actually be run.

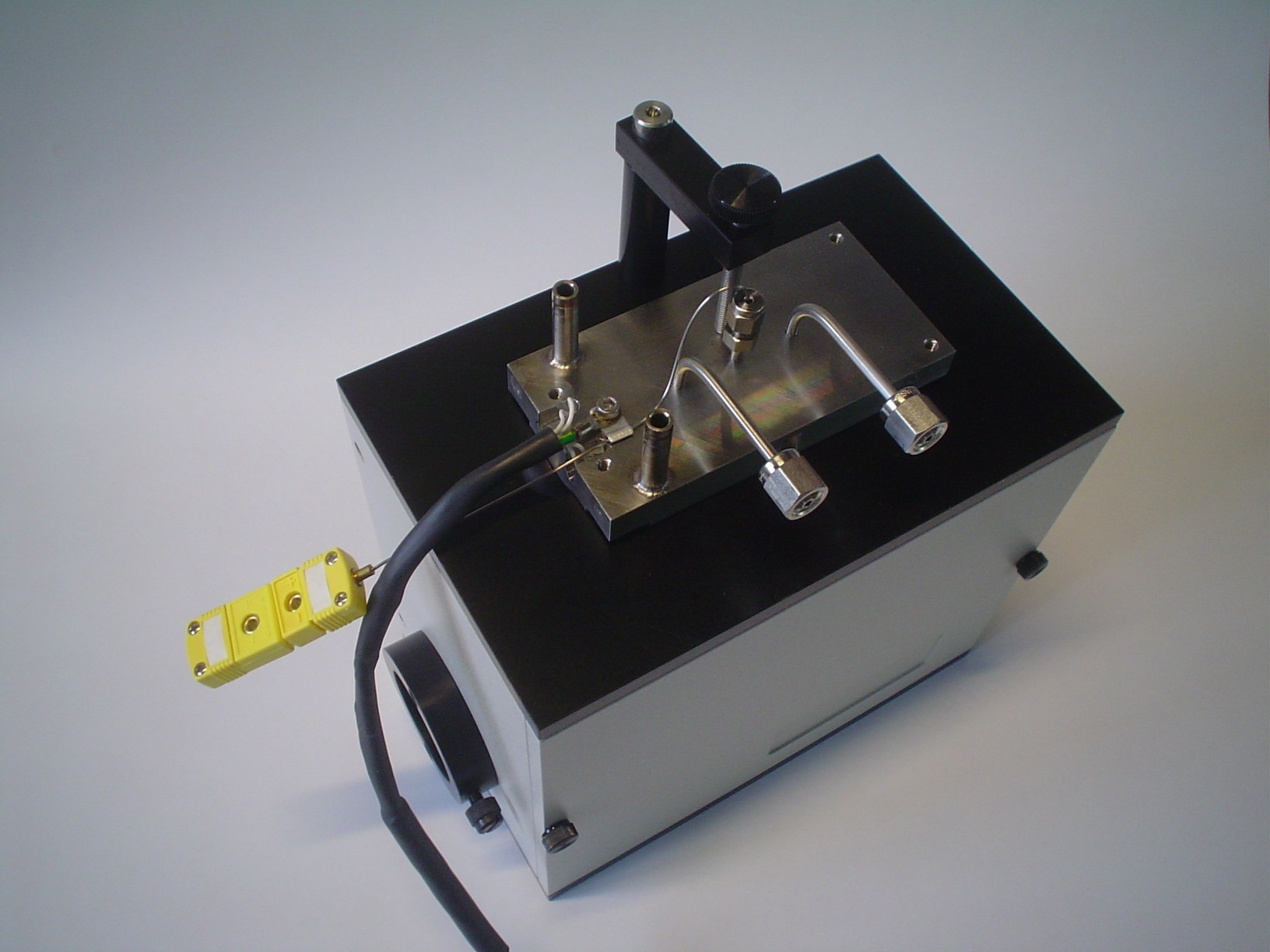

Image Credits: Custom flow cell design for horizontal ATR measurements with high pressure, high temperature (c. 300 °C) liquids. Specac

Your team blends decades of hands-on experience across applications, setup, and documentation. How does that collective memory shorten time-to-answer for new customers with novel samples?

Our Applications team brings together over 60 years of combined, hands-on experience across spectroscopy techniques, sample preparation, instrument setup, troubleshooting, and documentation. That collective experience allows us to recognize patterns quickly, even when customers present novel or unconventional samples.

In practice, very few samples are truly unprecedented. A new material often behaves like something we have encountered before under similar conditions. This allows us to anticipate challenges such as weak signal, scattering effects, or compatibility issues early, rather than relying on trial-and-error.

As a result, we can recommend the right technique or configuration upfront, dramatically shortening time-to-answer and helping customers reach reliable data faster. That experience is shared internally and continuously refined, allowing insight to compound over time and strengthening our ability to support new applications with confidence.

Jeff D’Agostino

Jeff has over 40 years' experience in the spectroscopy industry. He has been at Specac for more than ten years and now looks after the brand new applications laboratory.

Applications, Lab Capabilities & Hands-On Proof

Specac’s application expertise is now supported by a newly expanded Applications Lab at our Mount Kisco, New York facility. The lab was designed specifically around real-world FT-IR and UV-Vis-NIR workflows, allowing us to move seamlessly between ATR, diffuse reflectance, transmission, and specular reflectance measurements, as well as advanced environmental and in situ studies.

Importantly, the lab reflects the diversity of instruments our customers use every day, enabling demonstrations, feasibility studies, and training that feel immediately transferable to their own laboratories and workflows. To support this, the lab features instrumentation from many of the prominent spectrometer manufacturers in the industry, reflecting the platforms our accessories are routinely used with in real-world research and industrial environments.

Image Credits: Specac

Customizing Training for Different Users

The strength of the lab is not just its breadth of techniques, but how it enables hands-on learning. Whether working with a first-year PhD student or a time-pressed QC technician, we tailor training around what success looks like for that user.

For some, that means understanding fundamentals and experimental design; for others, it means speed, repeatability, and confidence in routine measurements. The same accessory may be used in both environments, but the training emphasis changes accordingly.

Formal Training & Outcomes

This approach extends into our formal training offerings, including in-house IR courses and customer workshops. Attendees will leave with practical competencies they can apply immediately, such as choosing the right spectroscopic technique, the right accessory for their sample, and how to prepare their samples correctly.

Because the training is grounded in real instruments, real accessories, and real samples, users return to their labs able to work independently and with confidence.

Bisirat Araya

Bisirat is also from the Harrick Scientific group, bringing over eleven years of experience to the role. For "Bisi", walking the customer through the details of a product, or closing the gap in knowledge between the physical product and their desired scientific outcomes, is key to the service that Specac provides.

Where do you most often see the “knowledge gap” in spectroscopy workflows, and how do you help close these gaps for the customer?

The most common knowledge gaps we see are in sample preparation, accessory selection, and the practical limits of spectroscopic techniques. Even users who understand spectroscopy theory well can encounter challenges when that theory is applied to real samples with specific mechanical, optical, or chemical constraints.

In practice, this often involves underestimating the impact of sample thickness, beam geometry, or chemical compatibility, or assuming an accessory can compensate for limitations in spectrometer configuration, such as purge conditions or detector sensitivity. Sample preparation is also frequently treated as a separate step rather than an integral part of the analysis, which can lead to poor reproducibility.

We address these gaps proactively by engaging early, before any accessory is selected. By understanding the full analytical context and asking targeted questions upfront, we help users choose solutions that align with both their scientific goals and operational constraints. This approach reduces trial-and-error and significantly shortens the path to reliable data.

You offer free 15-minute consultations with an Application Scientist. What kinds of problems are ideal for that first touch, and what signals tell you a deeper feasibility study is warranted?

The 15-minute consultation is designed to quickly assess whether a proposed approach is fundamentally aligned with the sample and measurement goal. These conversations are ideal for early-stage questions around technique selection, such as whether ATR, transmission, or reflectance is most appropriate, or whether an accessory is compatible with a sample’s physical and chemical properties.

A deeper feasibility study is warranted when the application involves non-standard samples, extreme operating conditions, or requirements that fall outside standard configurations. In those cases, additional testing or discussion ensures the chosen solution will deliver reliable data within the customer’s workflow.

Can you share a case where early questions about sample type, operating conditions, or instrument integration prevented downstream delays or mis-purchases?

One example involved a customer interested in using specular reflectance to analyze thin films on metallic substrates. While this initially seemed appropriate, further discussion revealed the films were only 5 to 10 nanometers thick. At that thickness, specular reflectance would not provide sufficient sensitivity.

Instead, we recommended a grazing-angle germanium ATR approach using the VariGATR accessory. The high refractive index of germanium and the grazing-angle geometry significantly enhanced surface sensitivity, resulting in stronger absorbance signals. By identifying the sample constraints early, we prevented a mis-purchase and helped the customer reach meaningful data much faster.

About Bisirat Araya

Bisirat holds a B.A. and M.S. in Chemical Engineering from Manhattan University and is an Applications Scientist at Specac-Harrick with over eleven years of experience at Harrick Scientific. She specialises in technical customer support, sample evaluations, equipment setup, and technical documentation.

Bisirat collaborates with customers to optimise equipment performance and works with applications and engineering teams to develop new products.

About Jim Delaney

Jim is the Applications Team Manager at Specac, with over 10 years of experience supporting advanced spectroscopy applications across research, industrial, and commercial environments. He leads a global applications team that partners closely with sales and product management, providing technical leadership throughout the customer engagement process. Jim works directly with customers to evaluate samples, optimize measurement approaches, and enable successful implementation of spectroscopy solutions. He also plays an active role in special/custom application development, technical training, and guiding new product direction through close collaboration with customers and B2B partners."

About Jeff D’Agostino

Jeff has over 40 years in the FT-IR spectrometer accessory industry, including work with three of the top four companies in the field.

He earned a B.S. in Chemistry from Central Connecticut State College (now University) and an A.S. in Chemical Engineering from Norwalk State Technical College.

His roles have included applications support, product management, training, sales, and marketing. Jeff has helped develop new IR accessories, presented at industry events, and authored publications. He is a member of the Coblentz Society, SAS, and ACS.

This information has been sourced, reviewed, and adapted from materials provided by Specac Ltd.

For more information on this source, please visit Specac Ltd.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.