Sponsored by QATMReviewed by Emily MageeFeb 17 2026

Accurate geological and mineralogical analysis begins long before the microscope or analytical instrument is switched on. In mining, exploration, and geoscience laboratories, sample preparation is the foundation of reliable results.

Image Credit: Shutterstock.com/Phawat

From heterogeneous ores and hard rock formations to fragile, porous minerals, each material presents its own preparation challenges.

Cutting, mounting, grinding, polishing, and thin sectioning must protect fragile structures and deliver reproducible surfaces. QATM combines equipment, consumables, and application know-how into an end-to-end preparation workflow built to maintain sample integrity.

End-to-end geology preparation workflow: Cutting, mounting/impregnation, grinding & polishing, and thin section preparation. Image Credit: QATM

Learn more about our expertise in Geology and Mining on our website

Why Preparation Quality is a Mining-Critical Variable

Geological samples are inherently complex. They vary widely in hardness, grain size, porosity, mineral composition, and structural integrity. Any damage introduced during preparation, such as microcracks, pull-outs, smearing, or thermal alteration, can compromise subsequent microscopic or analytical evaluation.

Reliable preparation ensures:

- Representative cross-sections of rocks, ores, minerals, and fossils

- Preservation of microstructures

- Flat, scratch-free surfaces suitable for optical microscopy, SEM, and image analysis

QATM’s preparation workflows are designed to maintain material integrity while delivering reproducible, high-quality surfaces, even for the most challenging geological specimens.

At-A-Glance Workflow: From “As Received” to “Analysis-Ready”

A robust geology workflow typically follows four connected steps:

- Cutting a representative piece from the starting material

- Mounting/impregnation (especially for porous, brittle, or powdered samples)

- Grinding and polishing to reach the required surface quality

- Thin sections when transmitted-light petrography is required

The key point: each step is a quality gate for the next one. The highest-polishing process cannot “fix” damage created during cutting.

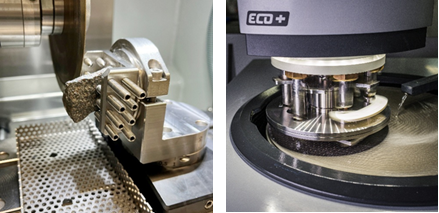

Cutting: Fast, Clean Sectioning Without Mechanical Damage

Cutting is where sample quality is either protected or quietly compromised.

To meet geology’s wide range of hardness and sensitivity, QATM offers multiple wheel options, including diamond, CBN, corundum, and silicon carbide. To safeguard the specimen from the very first step, QATM combines cutting performance with efficient coolant delivery that cools and lubricates the cutting interface directly.

This helps minimize thermal influence and keeps dust generation under control. Available in manual, semi-automatic, and fully automatic configurations, QATM cut-off machines enable fast, clean sectioning without damaging or deforming geological samples.

Precision cutting concept: wheel selection (diamond/CBN/corundum/SiC) and coolant supply to reduce thermal damage and dust formation. Image Credit: QATM

QATM Solution Highlight: Qcut 200 A (Precision Cutting)

QATM’s Qcut 200 A offers multiple operating modes (including grinding mode with diamond cup wheels) and process-support features such as cross feed, a “zone cutting” function, a honing device for diamond discs, and an integrated database for cutting processes.

Watch our video to see precision clamping devices in action.

Clamping devices precision I QATM

Video Credit: QATM

What Role Does Mounting Play in Reliable Geological Analysis?

Mounting stabilises the specimen, protects edges, and provides the mechanical support required for consistent grinding and polishing. In geology and mineralogy, mounting is especially important for porous, cracked, fissured, fine-grained, or fragile materials, where insufficient support can lead to edge break-out and loss of structural detail.

To match different sample requirements, we use three main mounting approaches:

- Hot mounting: performed under pressure and temperature, delivering excellent planarity and edge retention.

- Cold mounting: ideal for heat- or pressure-sensitive samples, with resin systems selected according to curing behaviour, hardness, and removal rate.

- UV mounting: the fastest option, using light-curing acrylic resins for transparent mountings without mixing.

For mineralogical samples, cold mounting with epoxy resins is the most common method. For thin sections, including thin sections prepared from powdered samples, we recommend low-viscosity epoxy systems to ensure pores and cracks are filled effectively, and powder particles are securely enclosed. For reliable light-microscopy evaluation, the refractive index of the mounting material should be close to that of glass to avoid optical distortion during transmitted-light analysis.

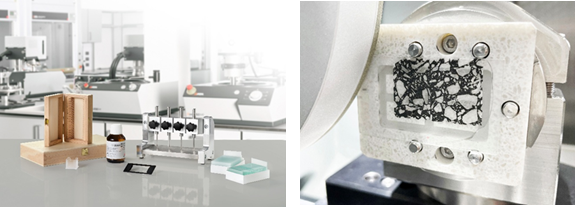

Vacuum Impregnation (When Porosity and Cracks Are the Real Challenge)

Vacuum impregnation is essential whenever pores, microcracks, or fissures would otherwise trap air and weaken edge stability during preparation.

Evacuate the vacuum container to draw air out of these cavities; under vacuum, a low-viscosity resin can then penetrate and stabilise the specimen. After filling the mould, place the sample under 2 bar overpressure for two hours to reduce bubble formation.

Keep in mind that light-curing mounting materials typically have higher viscosity, so complete impregnation of fine pores and cracks may not be achievable.

For laboratories that want to standardise these steps and handle other preparation challenges with confidence, QATM provides a dedicated Preparation Guide that brings together proven procedures, practical parameters, and expert know-how across the full geology and mineralogy workflow.

Vacuum impregnation principle for porous or cracked specimens: evacuation removes air, so low-viscosity resin penetrates cavities under vacuum. Image Credit: QATM

Access our free Preparation guide to learn more about best practices

Image Credit: QATM

Grinding and Polishing: Achieving Flatness, Contrast, and Repeatability

Grinding and polishing transform the mounted specimen into an analytical-ready surface. Geological samples often combine minerals with very different hardness levels, making controlled material removal essential.

QATM’s grinding and polishing systems range from manual and semi-automatic units to fully automated platforms, supported by an extensive portfolio of consumables. Diamond grinding discs, silicon carbide papers, polishing cloths, and diamond suspensions are carefully matched to the sample material and analysis objective.

Intelligent control of pressure, speed, and processing time ensures:

- High planarity across heterogeneous structures

- Minimal relief between mineral phases

- Excellent reproducibility for routine and research applications

In our experience, preparation choices are strictly linked to specimen type, for example:

- Rocks requiring smooth, flat, reflective surfaces

- Ores requiring fine, uniform, high-contrast surfaces

- Minerals requiring clear, clean, detailed surfaces

This approach allows laboratories to efficiently prepare samples for reflected and transmitted light microscopy, SEM analysis, and quantitative mineralogical evaluation.

While these principles form the technical basis of high-quality preparation, selecting the right parameters and workflows often requires deeper application experience - especially when dealing with complex or heterogeneous geological materials.

Our comprehensive Expert Guide provides beginners and experienced users with a structured guide to materialographic sample preparation. Numerous photographically documented examples, practical tips, and a new chapter on geology and mineralogy make this book your competent reference work - ideal for everyday and unusual preparation tasks.

Image Credit: QATM

Access our Comprehensive Expert Guide here

QATM Solution Highlight: High Throughput Solutions

QATM suggests manual/semi-automatic systems like Qpol 300 A1/A2, and fully automatic systems such as Qpol 250 BOT / Qpol 300 BOT using central pressure.

Complete range of grinding and polishing systems

Thin Sections: Revealing Geological History Layer by Layer

Thin section preparation is a cornerstone of petrographic analysis. By reducing a sample to a thickness of approximately 20–30 µm, mineral textures, grain boundaries, and optical properties become visible under polarized light.

QATM provides dedicated solutions for thin section preparation, offering a reliable and complete route:

- Grinding the mounted sample flat (example abrasive grain size 65-75 µm, depending on material) with low contact pressure, low speed, and good cooling, checking under a stereomicroscope after each step to avoid coarse scratches

- Bonding the dried sample to a glass slide using Qpox adhesives or UV-curing materials, and using a thin section press to reduce detachment or bubble formation

- “Pre-thinning” by cutting to roughly 300-1000 µm while maintaining plane parallelism (using vacuum clamping devices available for Qcut 150 A and Qcut 200 A)

- Final grinding to a typical thickness of 20-30 µm, with guidance that pores/cracks opened during pre-thinning should be closed (example medium: Qpox 94), and using optical appearance as a practical check (e.g., quartz should remain white; yellowish indicates too thick).

At QATM, we also define the key requirements for thin-section glass slides: uniform thickness with low tolerances, a defined refractive index, and a roughened surface to ensure secure bonding.

Thin section thickness control: pre-thinning to 300–1000 µm with plane parallelism, followed by grinding to 20–30 µm final thickness. Image Credit: QATM

What Makes QATM a Trusted Partner for the Mining Industry?

QATM’s strength lies not only in individual machines but in its holistic understanding of the preparation process. By offering perfectly matched equipment, consumables, and application expertise, QATM enables laboratories to standardize workflows, improve efficiency, and achieve consistent results.

Key advantages include:

- Deep application know-how in geology and mineralogy

- Complete preparation solutions from cutting to thin sections

- Robust, reliable equipment designed for demanding laboratory environments

- Expert support to tailor preparation methods to specific materials and objectives

For mining and geoscience professionals, this translates into greater confidence in analytical results, faster turnaround times, and a solid foundation for exploration, quality control, and research decisions.

Secure what you do: With QATM, geological and mineralogical analysis is built on precision you can trust.

Get in contact with our experts

This information has been sourced, reviewed, and adapted from materials provided by QATM.

For more information on this source, please visit QATM.