Sponsored by MicrotracReviewed by Emily MageeFeb 17 2026

The mining and geology industries form the backbone of modern infrastructure, technological development, and economic growth. These sectors depend on accurate and timely data to guide decisions in exploration, mineral processing, environmental management, and production of construction materials.

Image Credit: Shutterstock.com/domnitsky

In recent decades, particle size, shape, and surface charge analysis has become a prominent analytical approach, offering broad applicability to both fine and coarse geological materials.

Particle size and shape influence virtually every aspect of mining operations – from the transport and deposition of sediments in exploration environments to the extraction of valuable minerals in grinding circuits and the geotechnical stability of aggregates in civil engineering projects.

As mining operations strive for greater efficiency, better process control, and decreased environmental impact, the ability to quickly quantify particle size distribution (PSD) becomes increasingly valuable.

This article presents a selective overview of the mining value chain and how particle characterization knowledge can streamline the process.

Integration of laser diffraction and dynamic image analysis instruments, such as Microtrac's portfolio, provides reliable, robust data.

Basic Impact of Particle Size in Geology and Mining

Particle size affects geological materials on a fundamental level, influencing their physical, chemical, and mechanical properties. In exploration geology, grain size gives insight into depositional environments, erosional processes, and mineralization events.

During processing, grind size determines the separation of valuable minerals and the efficiency of downstream processing steps. In environmental monitoring, particle size affects sediment transport, dust generation, and tailings stability. Even in construction and geotechnical applications, particle size distribution directly affects compaction, strength, and permeability.

Traditional methods such as sieving and sedimentation have long been used to characterize particle size. However, these approaches can be slow, labor-intensive, and less effective for fine materials.

Laser diffraction systems measure the scattering angles of laser light passing through dispersed particles, wet or dry. The indirect size technique converts scattering patterns into a size distribution using a reliable model based on Mie theory.

Results are delivered quickly with low material consumption, in accordance with the requirements of ISO13320:2020. Systems like the Microtrac SYNC go further by integrating dynamic image analysis, allowing operators to simultaneously evaluate particle shape and morphology - data critical for understanding material properties such as mechanical strength and settling.

Applications of Particle Size in Mineral Exploration and Resource Characterization

During mineral exploration, geologists work to understand the distribution, origin, and context of mineralized zones. Particle size analysis provides a window into the geological history of a region by revealing details about sediment transport, weathering processes, and depositional environments.

Fine-grained sediments may indicate low-energy depositional settings such as floodplains or lacustrine environments, whereas coarse, angular particles may signal proximity to source material or tectonically active regions. In placer exploration, the particle-size distribution within alluvial deposits can help identify trap sites for heavy minerals such as gold or ilmenite.

Particle size distributions also assist with interpreting paleoenvironments and stratigraphy.

When combined with geochemical and mineralogical data, PSD helps delineate alteration halos, identify dispersion patterns, and improve the spatial resolution of resource models.

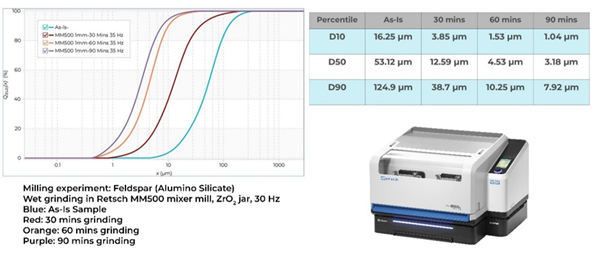

Operators can generate PSD data within minutes rather than hours, enabling more adaptive sampling strategies and improving the cost-effectiveness of field programs. Figure 1 illustrates a typical PSD curve derived from a milling experiment, demonstrating the level of detail obtainable through laser diffraction.

Figure 1. Particle size distribution from a controlled milling experiment. Image Credit: Microtrac

A Look Into Ore Processing and Milling Efficiency

Once ore is delivered from the mine, its processing cost and efficiency depend heavily on achieving the appropriate grind size. Comminution alone can account for 30-50 % of total energy use in a typical mineral processing plant, making real-time PSD monitoring essential for optimizing both energy consumption and mineral recovery (Anderson, 2014).

Laser diffraction provides high-frequency measurement capabilities that are well-suited for integration with automated plant control systems. By feeding PSD data directly into control loops, processing plants can regulate in real time.

These adjustments support more consistent grind sizes, reducing variability that could otherwise lead to overgrinding or insufficient extraction. Overgrinding produces excessive fines that can interfere with flotation or filtration, while undergrinding leaves valuable minerals locked within larger particles, reducing recovery.

In addition to enhancing efficiency, rapid PSD feedback enables operators to detect system upsets - such as changes in ore hardness, mill liner wear, or classifier malfunction - far earlier than traditional manual testing would allow. This leads to increased throughput, reduced operational risk, and more stable downstream processing.

Assisting With Flotation, Leaching, or Other Beneficiation Processes

Flotation and leaching circuits rely heavily on particle size, as both processes depend on maximizing the interaction between minerals, reagents, and liquid phases (CEEC, 2021). If particles are too coarse, flotation recovery drops due to insufficient release.

If particles are too fine, they may become entrained in froth or require excessive reagent addition. Similarly, leaching kinetics depend on surface area availability, which directly correlates with PSD.

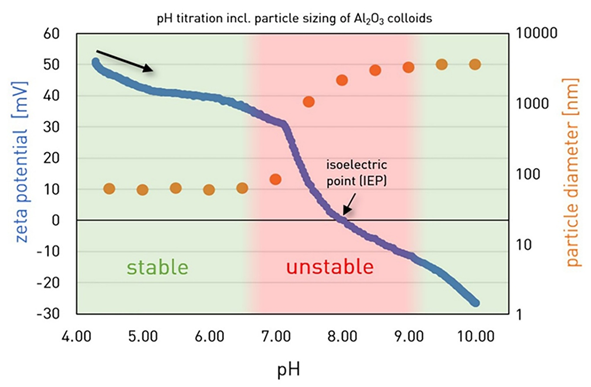

Dynamic Light Scattering (DLS) offers similar rapid, reproducible measurements that help maintain feed material within optimal particle size windows. This leads to improved reagent efficiency, enhanced selectivity, and higher recovery rates. Figure 2 demonstrates DLS with streaming Zeta Potential (ZP) analysis. Mapping particle charges reveals insights into slurry chemistry, dispersion behavior, and agglomeration tendencies.

Figure 2. Streaming zeta potential of alumina suspension during NaOH titration. Image Credit: Microtrac

For complex ores or fine-grained materials, the combination of PSD and colloidal stability data supports a more nuanced understanding of flotation performance.

By identifying where fine fractions may be contributing to poor froth stability or where coarse particles are failing to attach to air bubbles, treatment plants can adjust grinding, reagent dosages, or conditioning times to improve overall efficiency.

Environmental Impacts: How Characterization Helps Monitoring and Regulatory Compliance

Mining operations face strict environmental standards governing water quality, dust emissions, sediment discharge, and tailings management. Particle size plays an essential role in all these issues. Fine particles can remain suspended for long periods in water bodies, posing ecological risks and complicating settling processes.

Similarly, airborne respirable fractions, particularly those below 10 µm in diameter, present health and visibility concerns (Huang, 2023).

Regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and Environment and Climate Change Canada (ECCC) require quantifiable data for environmental reporting. The speed and repeatability of laser diffraction give operators the ability to respond rapidly to potential compliance issues.

For instance, if a tailings discharge begins to exhibit unexpectedly fine particle content, operators can quickly identify whether a grinding circuit upset, a cyclone malfunction, or a change in ore characteristics is responsible.

Dynamic Image Analysis Benefits Construction Aggregates, Cement Production, and Geotechnical Applications.

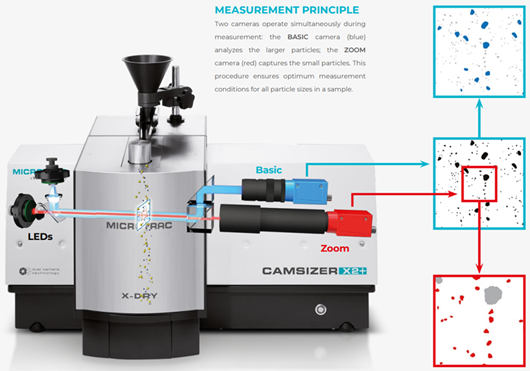

Dynamic image analysis (DIA) has become a central technique in modern particle characterization. DIA directly captures and evaluates individual particle images at high speed. This type of analysis produces statistically robust size and shape data from millions of particles in just a few minutes.

Real optical projections of particles in motion allow high-resolution size analysis, but also an understanding of how they are shaped. The size and shape results align with the practical needs of accurate gradation, consistent particle morphology, and reproducible data to control product performance.

Microtrac CAMSIZER systems apply this imaging approach to construction aggregates by using dual camera technology, as shown in Figure 5. Fine particles are recorded with high magnification, while coarse particles are captured in a large field of view, and the software merges both data sets into a seamless size distribution.

This eliminates the need for separate measurements or lens changes and ensures that wide grading materials. Sands, gravels, crushed rock, recycled aggregates, and complex mortar or plaster blends are accurately characterized in a single run. The method also handles non-free-flowing or cohesive materials effectively, especially when supported by air-pressure dispersion modules, revealing the true fine-fraction content that traditional sieving often misrepresents.

Figure 3 shows the dual camera technology, an integration of the basic and zoom cameras inside the Camsizer X2+. Image Credit: Microtrac

CAMSIZER DIA technology is a high-value technique for the construction materials sector, offering a modern alternative to sieve analysis with higher information content. For construction professionals, this means more reliable control of compaction behavior, water demand, permeability, strength development, and long-term durability of concrete and mortar.

For others in civil engineering labs, it delivers more dependable analytics and a deeper understanding of how particle size and shape drive material performance across the entire construction value chain.

Conclusion

Across mining, geology, and construction materials industries, understanding particle size and shape remains fundamental to optimizing performance, meeting regulatory expectations, and maintaining dependable product quality.

These characteristics influence nearly every stage of the value chain, from extraction and beneficiation to compliance and performance. As industries face increasing pressure to reduce environmental impact and improve products, the ability to reliably assess particle size and shape becomes a strategic advantage.

These properties offer direct insight into material behavior, helping industry professionals anticipate performance issues, adjust processes proactively, and ensure that both products and byproducts meet the specifications demanded by customers, regulators, and evolving market expectations.

In this way, particle characterization serves as an essential link between raw material variability and consistent industrial outcomes, supporting safer, more efficient, and more sustainable operations across the sectors that rely on particulate materials.

References and Further Reading

Anderson, C.D. (2014). Fundamentals of rare earth flotation surface chemistry: Electrokinetic phenomena. Mining, Metallurgy & Exploration, 31(3), pp.176–176. DOI: 10.1007/bf03402276. https://link.springer.com/article/10.1007/BF03402276.

CEEC (Coalition for Eco-Efficient Comminution). (2021). MINING ENERGY CONSUMPTION 2021. Available at: https://www.ceecthefuture.org/resources/mining-energy-consumption-2021

Huang, X. (2023). The Impact of PM10 and Other Airborne Particulate Matter on the Cardiopulmonary and Respiratory Systems of Sports Personnel under Atmospheric Exposure. Atmosphere, [online] 14(11), p.1697. DOI: 10.3390/atmos14111697. https://www.mdpi.com/2073-4433/14/11/1697.

ISO. ISO 13320:2020. Available at: https://www.iso.org/standard/69111.html

This information has been sourced, reviewed, and adapted from materials provided by Microtrac.

For more information on this source, please visit Microtrac.