Across many industries, particle analysis plays a key role in quality control, process monitoring, and contamination detection. Traditionally, when measuring particles, it is useful to have access to a laboratory equipped with complex assemblies and well-trained personnel.

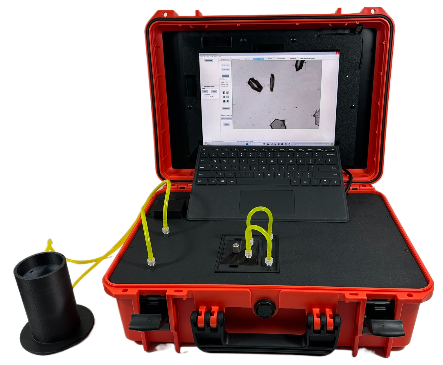

Image Credit: Vision Analytical Inc.

Yet accessing this set-up can impede decision-making processes, especially when immediate access to results is required, such as when in the field or on the production line.

To address these concerns, Vision Analytical created the Raptor Portable, a robust, feature-rich portable particle size and shape analyzer that uses Dynamic Image Analysis (DIA) to measure particle size, particle shape, and particle concentration in-situ.

Rather than relying solely on indirect calculations, Dynamic Image Analysis captures authentic particle images and produces accurate measurement data that can be used right away.

Watch the short video below to see a demonstration of Raptor Portable’s easy-to-use functionality:

Raptor Portable Particle Analyzer | How It Works + Easy Step-by-Step Operation

Raptor Portable overview and operation. Video Credit: Vision Analytical Inc.

What Does the Raptor Portable Measure?

The Raptor Portable was developed to generate essential particle metrics that have application significance in real-world scenarios as follows:

- Particle size distribution

- Particle shape analysis (morphology)

- Particle concentration/particle count

- High-quality particle images for visual confirmation and investigation

Having the capacity to acquire all four metrics in a single instrument gives operators more power beyond simply reporting a number. Operators can understand the exact goings-on inside a sample and, depending on the configured application, whether the sample being measured is a fluid, suspension, or particulate material.

Why Dynamic Image Analysis (DIA) Matters

Numerous conventional particle measurement techniques typically report particle size based on an assumed spherical shape. Yet, industrial real-world environments rarely produce particles that are perfect spheres. Shape can affect everything from how a product behaves to filter performance and contamination sources.

Dynamic Image Analysis (DIA) resolves this by generating real-time images of particles as they are transmitted through the measurement zone. The system uses these images to directly measure each particle and classify it based on both size and shape parameters.

This offers two key benefits:

- Direct Measurement (of particle size and particle shape).

- Visual evidence that supports faster troubleshooting and better decision-making, as operators have direct access to what the particles look like.

A Simple Workflow: From Sample to Results

The Raptor Portable is a favorite among operators for its ease of use. The simple, repeatable workflow was designed to make the instrument suitable for users in the lab and in industrial environments.

A standard workflow analysis is mapped out below:

- Prepare the sample

- Load the sample into the Raptor Portable

- Run the measurement

- Review results and particle images

- Export or report data as necessary

In just a matter of minutes, the user has access to particle shape and size distribution, concentration results, and thumbnail images that verify particle identity or contamination type.

Portable, Rugged, and Built for Real-World Use

The Raptor Portable is housed in a reinforced case with built-in portability features that facilitate testing across a wide variety of environments. This makes it the perfect solution for scenarios where conventional lab instruments are not fit for the task at hand.

Examples include:

- Field testing

- On-site quality control

- Remote facility sampling

- Process monitoring

- Rapid contamination investigation

With portable particle imaging, results can be easily integrated into decision-making at the location, eliminating delays caused by sending samples to centralized labs.

Available Measurement Ranges

The Raptor Portable supports analysis of a wide range of particle types and sizes due to its capability across multiple magnifications, including:

- Standard magnification: ∼1 to 300 μm

- Low magnification: ∼20 to 2500 μm

This flexibility allows users to synchronize the system configuration with their specific application, whether they are inspecting fine contaminants or larger particles.

More Than “Pretty Pictures”: Real Decision Support

While high-quality particle images are valuable, the built-in capabilities of the Raptor Portable mean it can do more than simply capture images. These include data visualization and analysis tools such as:

- Distribution plots

- Correlation plots

- Classification tools

- Manufacturing pass/fail capability

- Particle concentration reporting

By combining measurement data with particle image capabilities, users can rapidly make informed decisions with confidence, even when particle identification is central to the problem-solving process.

Typical Applications for the Raptor Portable

Portability combined with real particle imaging makes the Raptor Portable a valued and well-trusted instrument across a diverse range of industries and workflows, including:

- Field-based particle testing

- Fluid cleanliness investigation

- General quality control for raw materials

- Particle contamination monitoring

- Process troubleshooting

- Research & development

In fluid-related applications, particle images can help identify contamination sources, such as wear, debris, fibers, sand, and corrosion particles. This allows maintenance and engineering teams to respond quickly and address any issues.

This information has been sourced, reviewed and adapted from materials provided by Vision Analytical Inc.

For more information on this source, please visit Vision Analytical Inc.