In industries where dry powder analysis is essential, such as pharmaceuticals, cement production, additive manufacturing, and beyond, accuracy, efficiency, and adaptability are key. But until now, most dry powder systems have been bulky, stationary, and difficult to fit into fast-paced or mobile work environments.

To this end, Vision Analytical Incorporated is excited to introduce the Raptor Portable Dry Powder Analyzer - the first system of its kind designed to deliver high-performance dry powder analysis in a truly portable format.

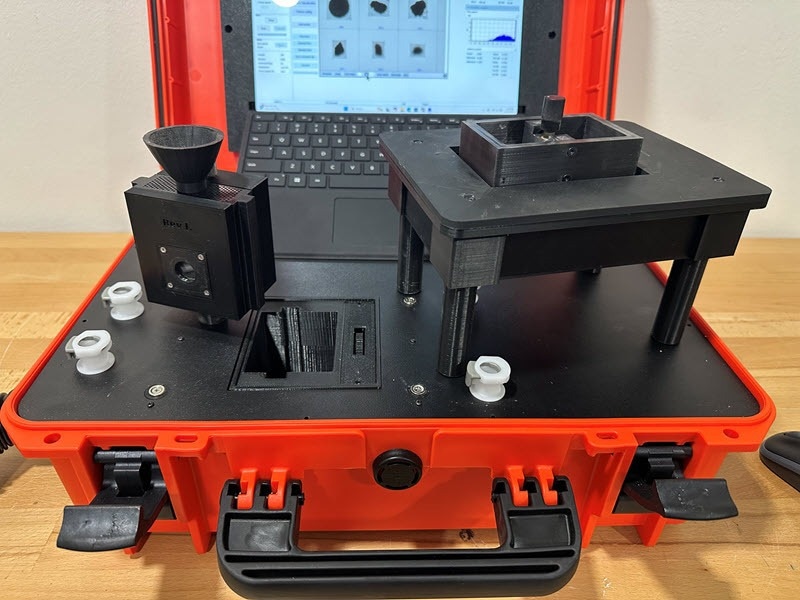

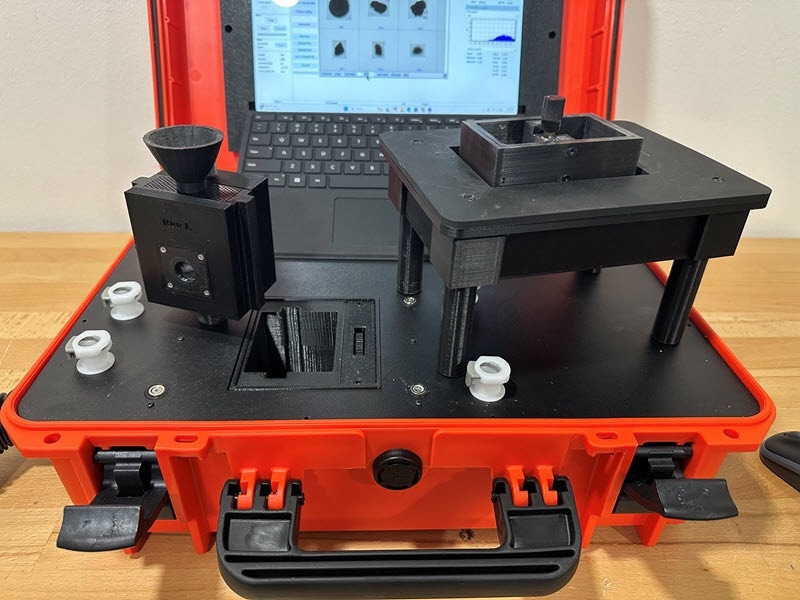

Dry Powder Module on Raptor Portable particle size and shape analyzer. Image Credit: Vision Analytical Inc.

Why Portability Matters in Dry Powder Analysis

Traditional dry powder systems often require transporting samples to a separate lab for analysis - a step that can lead to:

- Risk of sample contamination

- Wasted time

- Slower, less efficient production workflows

The Raptor Portable Dry Powder Analyzer offers a smarter alternative. It brings advanced particle size and shape analysis directly to where it’s needed - whether that’s on the production line, in a clean room, or out in the field. This means faster insights, fewer disruptions, and more confident decision-making right at the point of need.

Key Features of the Raptor Portable Dry Powder Analyzer

- Thumbnail Images - With thumbnail images as objective evidence of what’s in your sample, you don’t need to be an expert to SEE what’s happening in your process and make a decision in the field.

- Truly Portable - Lightweight, compact design that fits into existing workflows without disruption.

- High-Precision Measurement - Leveraging dynamic image analysis to deliver particle size and shape information with exceptional accuracy.

- Rugged Design - Built for mobility while maintaining the robustness needed for industrial environments.

- User-Friendly Interface & Tools - Intuitive dashboard with tools allowing for FAST decision-making in the field. No experts required.

- Versatile Application - Engineered to perform reliably across a wide range of powders: pharmaceutical excipients, cement powders, specialty chemicals, and more.

Dry Powder Module on Raptor Portable particle size and shape analyzer. Image Credit: Vision Analytical Inc.

Industries That Will Benefit

- Advanced Manufacturing & 3D Printing: Optimize powder bed fusion and other additive manufacturing processes by ensuring the right particle characteristics are maintained.

- Cement and Construction Materials: Monitor particle size distribution and material consistency on-site to ensure product quality and optimize formulation.

- Chemical Manufacturing: Analyze specialty powders without interrupting manufacturing flow or compromising sample integrity.

- Pharmaceutical Industry: Perform real-time analysis of active ingredients and excipients without leaving the cleanroom or production site.

Setting a New Standard

With the Raptor Portable Dry Powder Analyzer, Vision Analytical Inc. is setting a new standard for what's possible in powder analysis. It's more than just a piece of equipment - it’s a practical tool for faster insights, improved product quality, and more responsive operations.

Whether you're ensuring pharmaceutical quality, producing high-grade cement, or pushing the boundaries of advanced manufacturing, the Raptor gives you the ability to analyze with speed, precision, and mobility - right where the work happens.

Raptor Portable Analyzer: Dry Powder Module Demonstration for Particle Analysis

Video Credit: Vision Analytical Inc.