The BIOPROCESS project focuses on enhancing the mechanical and barrier properties of bioplastics to produce films for flexible packaging in the food, cosmetics, personal hygiene, detergent, and cleaning sectors.

This project is funded by the Valencian Institute of Competitiveness and Innovation (IVACE+i) through ERDF funds.

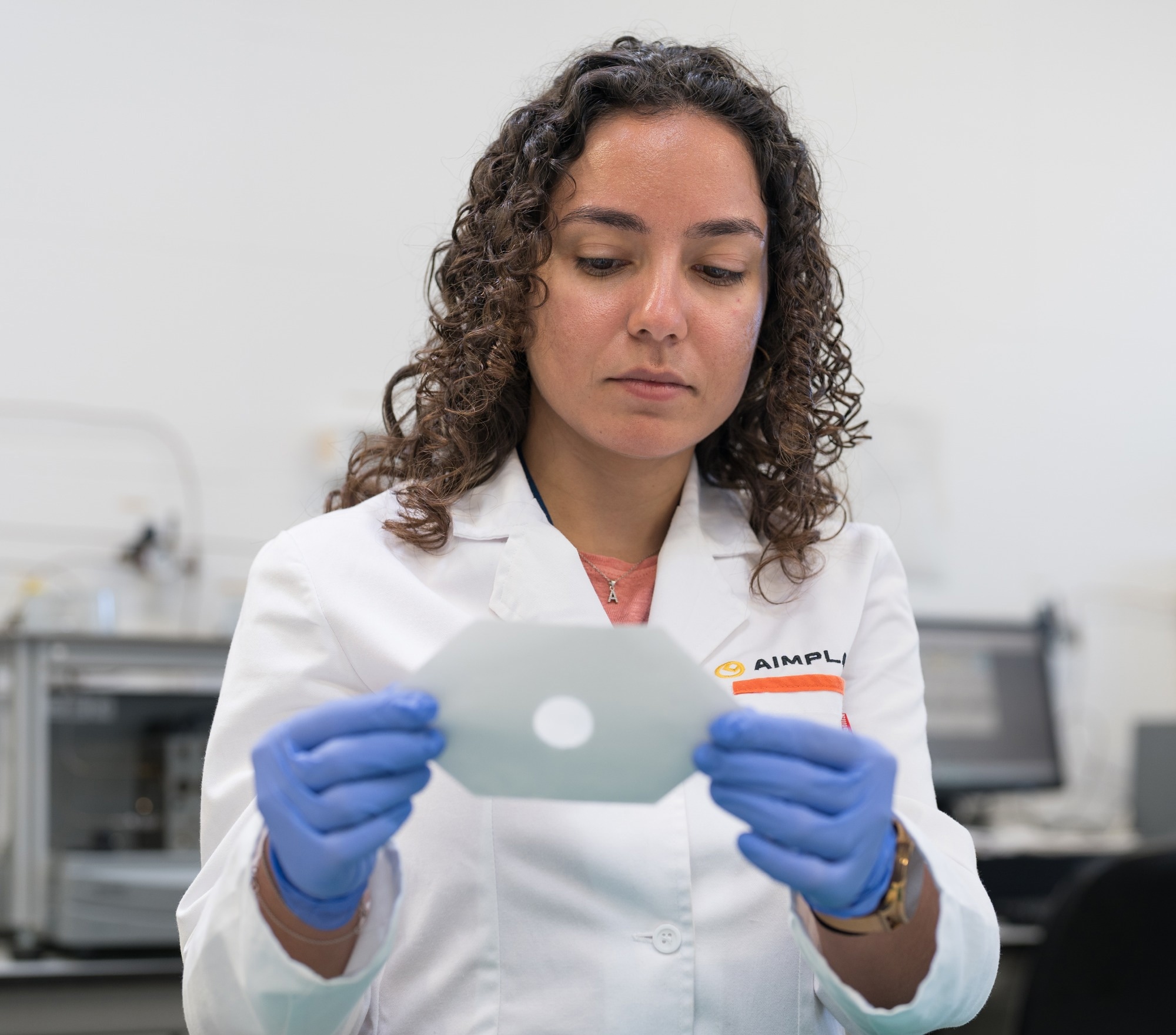

Image Credit: AIMPLAS

The use of bioplastics in packaging applications is emerging as a more sustainable alternative to conventional non-biodegradable plastics derived from fossil sources. However, further research is needed to ensure that biodegradable and/or compostable plastics can meet the necessary requirements to preserve and extend the shelf life of packaged products.

In this context, the BIOPROCESS project, led by the Plastics Technology Centre (AIMPLAS), aims to improve the mechanical and barrier properties of bioplastics to produce films for high-performance flexible packaging in sectors such as food, cosmetics and personal hygiene, detergents, and cleaning. The research involves two collaborating companies: Potato Bioplastics, a manufacturer of new bioplastics from renewable sources, and Gaviplas, a flexible film manufacturer.

Alicia Naderpour, Packaging Researcher at AIMPLAS, stated: “In BIOPROCESS, we have adopted the one-step approach for producing films from natural polymers, as it offers significant advantages in terms of efficiency, sustainability, product quality, and preservation of the natural properties of the materials. Additionally, the goal is to enhance the properties of bioplastics by orienting polymer chains for packaging applications without compromising their biodegradability and/or compostability.”

The use of bioplastics in the packaging sector, she added, “is proposed as an alternative to conventional plastics in cases where food residues remain in the packaging, making recycling difficult. Therefore, using bioplastics in such applications allows for the organic recovery of packaging waste to produce high-quality compost.”

In the BIOPROCESS project, AIMPLAS has applied Machine Direction Orientation (MDO) extrusion technology with various commercial bioplastics to produce these flexible biodegradable and/or compostable films. It has also developed new formulations of natural polymers, such as polysaccharides and animal and plant proteins, to study the modification of their mechanical and barrier properties when processed through non- oriented sheet extrusion and MDO extrusion.

These naturally sourced materials may come from algae, corn or potato starch, gelatins, or proteins, and in many cases are by-products of various industries, adding value to these low-cost materials and making them good candidates for use in sustainable packaging applications.

As Rosa González, lead researcher of the Packaging Cluster at AIMPLAS, emphasized, “The use of chemically unmodified natural polymers is gaining ground in these applications, as they are suitable for manufacturing packaging and plastic products that are banned under the SUP directive. However, these materials must have the appropriate characteristics to be processed using conventional packaging manufacturing technologies, such as extrusion processing, and must also meet the necessary requirements to preserve the products they contain.”

Image Credit: AIMPLAS

The BIOPROCESS project is part of the 2024 call for aid aimed at technology centers in the Valencian Community for R&D projects in collaboration with companies, promoted by the Valencian Institute of Competitiveness and Innovation (IVACE+i), with funding from the European Union’s European Regional Development Fund (ERDF) under the 2021–2027 Operational Program.