Michael Müller, our renowned head of the software department at NETZSCH Analyzing & Testing, will moderate the event and set the stage for a dynamic and insightful experience.

December 10, 2025 | 9 - 9:30 a.m. CET / 4 - 4:30 p.m. Chinese Time / 1:30 - 2 p.m. Indian Time

December 10, 2025 | 4 - 4:30 p.m. CET / 10 - 10:30 a.m. Eastern USA Time

DSC in. Composition out. Powered by Proteus® Now Quantify and DSC 300 Caliris®

Image Credit: NETZSCH-Gerätebau GmbH

Dr. Natalie Rudolph

Division Manager Polymer

With Proteus® Now Quantify, polymer analysis becomes faster, easier and more objective than ever.

The cloud-based, AI-driven platform automatically quantifies polymer blends from one DSC measurement - no expert interpretation required.

Together with the advanced features of the DSC 300 Caliris®, laboratories gain a powerful workflow for quality control and recycling applications.

What’s new on the DSC side

- DSC Camera – captures images of the sample inside the crucible and links visual effects (bubbling, deformation, residues) to thermal events

- Automatic Piercing Device (now standard) – safely pierces sealed pans just before measurement, ideal for volatile or hygroscopic samples and 24/7 operation

- EcoMode – schedules downtime to save gas and energy costs during idle periods

Why Quantify matters

- Automatic polymer quantification from a single DSC run

- Results within seconds, even for complex or overlapping melting peaks

- AI-powered accuracy, trained on thousands of data sets for high accuracy

- Uncertainty metric (RMSE) for transparent confidence displayed with every result

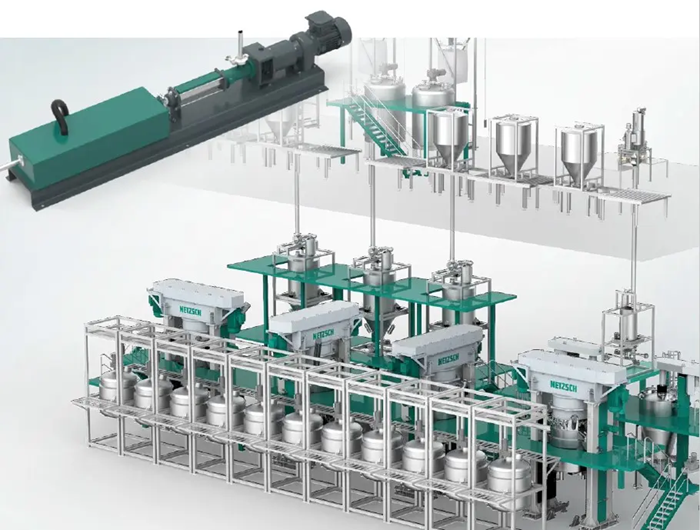

Stop Scrap. Stabilize Coating. Control Viscosity in Real Time – With Novanti

Image Credit: NETZSCH-Gerätebau GmbH

Onur Özgül

Application Expert Rheology

In modern lithium-ion battery production, slurry viscosity determines whether electrode coatings are uniform, stable, and defect-free.

With the NETZSCH Novanti inline rheometer, viscosity is no longer checked by intermittent lab tests - it is measured continuously, directly in the production line. Manufacturers gain real-time insight, rapid corrective action, and truly stable processes at industrial scale.

- Scrap & Cost Reduction

- Consistent Coating = Better Cell Performance

- Real-time control instead of delayed lab testing

- Better sustainability & less waste

UL 94 Classic: Test With Confidence. Stay Compliant. Spend Less.

Image Credit: NETZSCH-Gerätebau GmbH

Stephan Strickmann

Fire Testing Solution Expert

Fire safety is non-negotiable - and UL 94 is the globally recognized standard to classify how plastics behave when exposed to a small open flame. With UL 94 Classic, you get a rugged, budget-friendly rig that delivers fully compliant results without unnecessary extras.

It helps manufacturers in electronics, appliances, automotive, and industrial applications prove material safety by assessing self-extinguishing behavior, burn time, and flaming droplets - building confidence with customers and regulators while keeping costs in check.

- Full UL 94 compliance - same standard, same results as high-end systems

- Around 50% more affordable than supreme UL 94 system

- Rugged, reliable construction with precise manual burner adjustment

- No unnecessary extras - essential functionality, clean workflow, dependable results

MMC 315 Nexus®: Detect Hazards, Quantify Heat, Design Safer Processes.

Image Credit: NETZSCH-Gerätebau GmbH

Dr. Ekkehard Füglein

Head of Customer Training, Expert in Adiabatic Reaction Calorimetry

The MMC 315 Nexus® is a modular benchtop calorimeter that combines multiple calorimetry methods in one platform.

From adiabatic ARC testing to rapid screening and battery calorimetry, it delivers true adiabatic conditions for detecting thermal runaway and characterizing exothermic behavior. Users can screen materials for hazards, measure heat generation during charge/discharge, and calculate battery efficiency.

The system automatically recognizes plug-and-play modules, turning worst- case events into actionable data such as heat of reaction, pressure rise, and TMR. This enables safer scale-up, smarter cooling and reactor design, and faster decision-making.

- Multiple calorimetric methods in one flexible platform - ARC, scanning, battery calorimetry, and more

- Modular design - exchangeable modules with automatic recognition and calibration data included

- High precision safety data - adiabatic testing, self-heating detection, pressure rise, heat of reaction, TMR, etc.

- Battery-focused calorimetry - heat flow, efficiency, voltage/current control, True Joule calibration, minimal contact resistance

Get to Know Our Speakers

Michael Müller

Head of Software Department

TECH TALK Moderator

Dr. Natalie Rudolph

Division Manager Polymer

Introduction to DSC 300 Caliris® and Proteus® Now Quantify

Onur Özgül

Application Expert Rheology

Presents NETZSCH Novanti Inline Rheometer

Stephan Strickmann

Fire Testing Solution Expert

Introduction to UL 94 Classic

Dr. Ekkehard Füglein

Head of Customer Training Expert in Adiabatic Reaction Calorimetry

Presenting MMC 315 Nexus®