HFM 706 Lambda Series provides precise thermal conductivity measurements customized to your sample size.

Three Instrument Versions for Every Sample Size: Small, Medium, and Large

The HFM 706 Lambda Series comes in three versions, small, medium, and large, each of which is adapted to fit your specific sample dimensions. Whether evaluating small laboratory specimens or large industrial materials, the models provide accurate and dependable results.

HFM 706 Lambda Small Heat Flow Meter

Highlights

- The small version of the HFM 706 Lambda series is ideal for samples up to 203 mm×203 mm×51 mm in height. The Medium and Large variants can handle larger samples, giving versatility across applications.

- High-sensitivity heat flux transducers for accurate thermal analysis: The HFM 706 Lambda Series uses dual heat flux transducers to continuously monitor heat flow with exceptional sensitivity and accuracy. Its advanced calibration process relies on reference materials with known thermal conductivity, and by combining multiple calibration methods, it ensures consistently high measurement precision. The result is reliable, reproducible data every time.

- Achieve faster results and enhanced performance with cutting-edge Peltier technology: Experience precise temperature control with our advanced Peltier system for both hot and cold plates. Powerful bidirectional Peltier elements, combined with an external chiller, enable rapid and accurate heating and cooling. This optimized system quickly reaches thermal equilibrium, delivering consistent, reliable data in less time, and helping your lab work more efficiently.

- The optimized test chamber design provides reliable results and minimal condensation. The innovative test chamber minimizes environmental interference and greatly reduces condensation inside the chamber and on plate surfaces. For even greater control, an optional dry gas purge feature maintains optimal humidity levels, ensuring consistent test conditions and enhancing measurement reliability.

- The HFM 706 Lambda hardware and software assess the samples' specific heat capacity (cp), resulting in a full thermal profile. This dual-function capability broadens the scope of measurements and gives deeper insights into material attributes for research and quality control.

Image Credit: NETZSCH-Gerätebau GmbH

HFM 706 Lambda Medium Heat Flow Meter

Highlights

- The medium version of the HFM 706 Lambda is ideal for samples up to 305 mm x 305 mm x 105 mm in height. The Small and Large variants can handle both smaller and larger samples, giving you flexibility across different applications.

- The HFM 706 Lambda Medium version uses dual heat flux transducers to continuously monitor heat flow with exceptional sensitivity and accuracy. Its advanced calibration process relies on reference materials with known thermal conductivity, and by combining multiple calibration methods, it achieves consistently high measurement precision. The result is reliable, reproducible data every time.

- Achieve faster results and enhanced performance with cutting-edge Peltier technology. This state-of-the-art Peltier system delivers precise temperature control for both hot and cold plates. Powerful bidirectional Peltier elements, paired with an external chiller, provide rapid and accurate heating and cooling. This optimized setup quickly reaches thermal equilibrium, ensuring consistent, reliable data in less time and boosting your lab’s efficiency.

- The test chamber minimizes environmental interference and significantly reduces condensation inside the chamber and on plate surfaces. For even greater control, an optional dry gas purge feature maintains optimal humidity levels, ensuring consistent test conditions and enhancing measurement reliability.

- The HFM 706 Lambda hardware and software also measure a sample’s specific heat capacity (cp), producing a complete thermal profile. This dual-function capability expands the scope of your measurements, delivering deeper insights into material properties for both research and quality control.

Image Credit: NETZSCH-Gerätebau GmbH

HFM 706 Lambda Large Heat Flow Meter

Highlights

- The large HFM 706 Lambda system is ideal for use with samples up to 611 mm x 611 mm x 200 mm in height. It has a second opening opposite the front door, which allows for inserting different-length specimens. Insulation panels can be tested with excess material extending beyond the front and back. This is useful for vacuum insulation panels (VIPs), which are often supplied as long panels.

- High-sensitivity heat flux transducers for accurate thermal analysis. The HFM 706 Lambda Series is equipped with dual heat flux transducers that continuously monitor heat flow with exceptional sensitivity and accuracy. The system's advanced calibration process uses reference materials with known thermal conductivity. Thanks to this combination approach, high measurement precision is achieved. This way, you get reliable, reproducible data every time.

- Achieve faster results and enhanced performance with modern Peltier technology. Experience precise temperature management with our advanced Peltier temperature control system for hot and cold plates. Powerful bidirectional Peltier elements, paired with an external chiller, deliver rapid and accurate heating and cooling. This optimized control quickly reaches thermal equilibrium, providing reliable, consistent data in less time and enhancing your lab’s productivity and efficiency.

- The optimized test chamber design allows you to achieve reliable results with minimal condensation. The test chamber minimizes environmental interference and significantly reduces condensation effects inside the testing chamber and on the plate surfaces. For even better control, an optional dry gas purge feature maintains optimal humidity levels, creating consistent test conditions and enhancing measurement reliability.

Image Credit: NETZSCH-Gerätebau GmbH

Energy-Saving Eco and Idle Modes

Today, the focus on saving energy and using it efficiently has never been greater. Around the world, industries and academia are working to find better ways to conserve energy and make use of alternative resources.

To support these efforts, the HFM 706 Lambda Series includes two programmable energy-saving standby modes: Eco Mode and Idle Mode.

- In Eco Mode, both the plate temperature control and the chiller are completely shut down, cutting energy use to nearly zero during long idle periods, such as nights and weekends. This greatly reduces operational costs and minimizes environmental impact.

- In Idle Mode, the chiller runs at low power (0.5–1.0 kW) to maintain plate temperatures at preset levels, allowing measurements to restart quickly while still using significantly less energy than full operation.

Together, these modes maximize energy efficiency, lower CO2 emissions, and support sustainable lab operations, without compromising readiness or performance.

Method

Thermal Conductivity - A Key Parameter for Improved Energy Efficiency

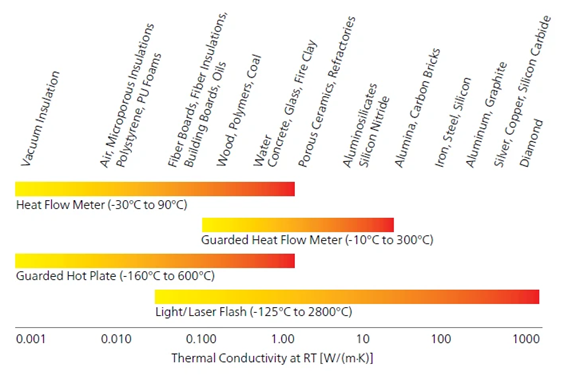

Thermal conductivity measures a material's capacity to carry energy. It measures how easily heat can pass through a material. The steady-state approach, commonly known as the heat flow meter method, is the most widely used technique for measuring thermal conductivity.

Image Credit: NETZSCH-Gerätebau GmbH

The HFM is a precise, fast, and easy-to-use instrument for measuring the low thermal conductivity (λ) of insulation materials.

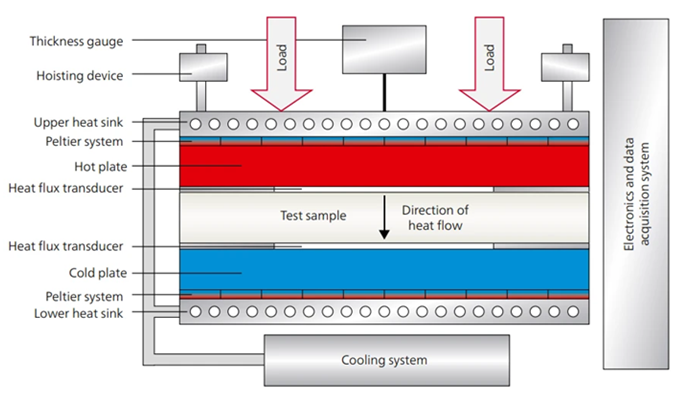

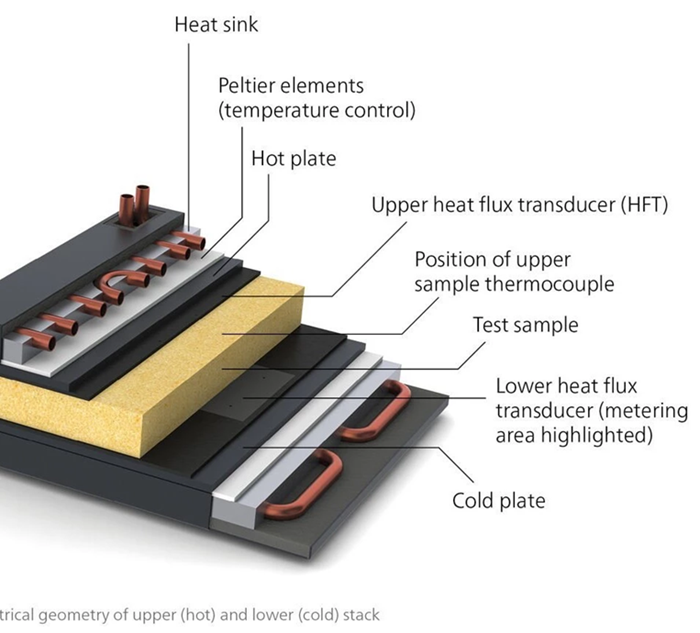

In a heat flow meter (HFM), the test specimen is placed between two heated plates that are controlled to a user-defined mean sample temperature and temperature gradient. This setup measures the heat flowing through the specimen. The sample thickness (L) is determined by an internal thickness gauge, or - if preferred - the user can set and drive to a desired thickness, which is especially useful for compressible samples. Heat flow (Q) is measured by two calibrated heat flux transducers, each covering a large area on both sides of the specimen.

Once thermal equilibrium is reached, the test is complete. The heat flux transducer output is calibrated using a reference standard. To calculate λ and thermal resistance (R), the system uses the average heat flux (Q/A), the sample thickness (L), and the temperature gradient (ΔT), in accordance with Fourier’s Law.

Image Credit: NETZSCH-Gerätebau GmbH

Which Questions Can be Answered with a Heat Flow Meter?

- How can I ensure the quality of my insulation material production?

- How does this change with the weather, and how can you improve it?

- What is the heating/cooling load of a building?

- What is the right thickness for my insulation material so that it meets the national and international guidelines for building insulation?

Material characteristics such as thermal diffusivity and thermal conductivity need to be well understood to address inquiries of this kind effectively.

For analyzing low-conductivity materials, such as fiber insulation or vacuum insulation panels, NETZSCH offers a range of HFMs designed to accommodate different sample sizes and temperature ranges.

Cross-section model. Image Credit: NETZSCH-Gerätebau GmbH

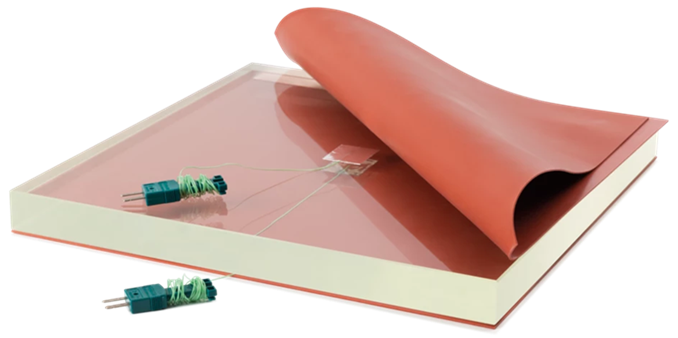

Thermocouples. Image Credit: NETZSCH-Gerätebau GmbH

Thermocouples are placed in the specimen's center. Image Credit: NETZSCH-Gerätebau GmbH

The key material parameter in this context is thermal conductivity - the amount of heat per second that flows through a material layer 1 meter thick and 1 m2 in area when there is a temperature difference of 1 K. The thicker the material layer, the greater its thermal resistance (R-Value), meaning it resists the flow of heat more effectively. The reciprocal of thermal resistance is thermal transmittance (U-Value), which is typically specified for structural components.

Whether it’s expanded polystyrene (EPS), extruded polystyrene (XPS), PU rigid foam, mineral wool, bloated perlite, foam glass, cork, fleece, or natural fiber materials - or building materials containing phase change materials, aerogels, concrete, plaster, polymers, or even high-performance insulation like vacuum insulation panels (VIPs) - the new HFM 706 Lambda applies a standardized method for measuring thermal conductivity. This method is equally suited for both research and development and quality assurance applications.

Benefits

The HFM 706 Lambda Series is an advanced range of instruments designed for accurate, efficient thermal conductivity measurements across a wide variety of materials, including insulation, polymers, phase-change materials, aerogels, and non-wovens. Built for precision and ease of use, it features a quick setup process with factory calibration using internationally certified reference materials, ensuring reliable results right from the start.

Offering measurement speeds up to 40 % faster than previous models, the series also includes energy-saving Eco and Idle modes, which reduce power consumption without sacrificing performance. Closed test chambers maintain optimal conditions by minimizing environmental interference and preventing condensation, delivering consistent, high-quality data.

Among the innovative capacities are:

- Accurate determination of sample thickness and parallelism using a two-axis inclinometer

- High throughput enabled by motorized plate and door movement

- Extended thermal conductivity range with external thermocouple support

Sophisticated features, including the drive-to-thickness function and heat flux transducer (HFT) multi-calibration, improve measurement accuracy and precision. Through stability configuration management, the HFM 706 Lambda Series conforms with industry standards and enables complete quality assurance documentation.

Its intuitive design guarantees seamless usage in a variety of languages and operating systems. To provide a thorough thermal analysis in a single, adaptable device, the instrument also provides specific heat capacity (Cp) measurement utilizing the step approach.

Accordance to National Standards

The HFM 706 Lambda Series is designed in accordance with multiple relevant standards, including ASTM C518, ISO 8301, JIS A1412, DIN EN 12667, and DIN EN 12664 (Large Version only).

Specifications

HFM 706 Lambda Small. Source: NETZSCH-Gerätebau GmbH

| HFM 706 Lambda Small |

| Standards |

ASTM C518, ISO 8301, JIS A1412, DIN EN 12667, DIN EN 12664 |

| Type |

Bench-top device |

Thermal

conductivity

range |

0.007 to 2 W/(m·K)**

2.0 W/(m·K) achievable with optional instrumentation kit, recommended for hard materials and those with higher thermal conductivity

Performance data:

- Accuracy: ± 1% to 2%

- Repeatability: ± 0.25%

- Reproducibility: ± 0.5%

→ All performance data is verified with NIST SRM 1450 D (thickness 25 mm)

|

| Plate temperature range |

-20 °C to 90 °C |

| Air-tight system |

Sample compartment with possibility to introduce purge gas |

Metering area heat

flux transducer |

102 mm x 102 mm |

| Chiller system |

External; constant temperature setpoint over plate temperature range |

| Plate temperature control |

Peltier system |

| Plate motion |

Motorized |

Plate

thermocouples |

Three thermocouples on each plate, type K (two extra thermocouples with instrumentation kit) |

Thermocouple

resolution |

± 0.01 °C |

Number of

setpoints |

Up to 99 |

Specimen

sizes (max.) |

203 mm x 203 mm x 51 mm |

Variable load/

contact force |

0 to 854 N (21 kPa on 203 x 203 mm2)

Force-controlled adjustment of the contact force or the desired thickness, and thus density, of compressible materials |

Thickness

determination |

- Automatic measurement of mean sample thickness

- Four-corner thickness determination via inclinometer

- Compliance to non-parallel specimen surfaces

|

Software

features |

- SmartMode (incl. AutoCalibration, report generation, data export, wizards, user methods, predefined user definable parameters, user-defined parameters, cp determination, etc.)

- Measurement History Report

- Enhanced Export Settings

- Storage and restoration of calibration and measurement files

- λ90/90 Report

- Plot of plate/mean temperatures and thermal conductivity values

- Monitoring of heat flux transducer signal

|

** Please note: In the very low thermal conductivity range, accuracy of Lambda (λ) values can be limited

HFM 706 Lambda Medium. Source: NETZSCH-Gerätebau GmbH

| HFM 706 Lambda Medium |

| Standards |

ASTM C518, ISO 8301, JIS A1412, DIN EN 12667, DIN EN 12664 |

| Type |

Bench-top device |

Thermal

conductivity

range |

0.002 to 2 W/(m·K)**

Small and Medium: 2.0 W/(m·K) achievable with optional instrumentation kit, recommended for hard materials and those with higher thermal conductivity

Performance data:

- Accuracy: ± 1% to 2%

- Repeatability: ± 0.25%

- Reproducibility: ± 0.5%

→ All performance data is verified with NIST SRM 1450 D (thickness 25 mm)

|

| Plate temperature range |

-20 °C to 90 °C, optional: -30° to 90 °C |

| Air-tight system |

Sample compartment with possibility to introduce purge gas |

Metering area heat

flux transducer |

102 mm x 102 mm |

| Chiller system |

External; constant temperature setpoint over plate temperature range |

| Plate temperature control |

Peltier system |

| Plate motion |

Motorized |

Plate

thermocouples |

Three thermocouples on each plate, type K (two extra thermocouples with instrumentation kit) |

Thermocouple

resolution |

± 0.01 °C |

Number of

setpoints |

Up to 99 |

Specimen

sizes (max.) |

305 mm x 305 mm x 105 mm |

Variable load/

contact force |

0 to 1930 N (21 kPa on 305 x 305 mm2)

Force-controlled adjustment of the contact force or the desired thickness, and thus density, of compressible materials |

Thickness

determination |

- Automatic measurement of mean sample thickness

- Four-corner thickness determination via inclinometer

- Compliance to non-parallel specimen surfaces

|

Software

features |

- SmartMode (incl. AutoCalibration, report generation, data export, wizards, user methods, predefined user definable parameters, user-defined parameters, cp determination, etc.)

- Measurement History Report

- Enhanced Export Settings

- Storage and restoration of calibration and measurement files

- λ90/90 Report

- Plot of plate/mean temperatures and thermal conductivity values

- Monitoring of heat flux transducer signal

|

** Please note: In the very low thermal conductivity range, accuracy of Lambda (λ) values can be limited.

HFM 706 Lambda Large. Source: NETZSCH-Gerätebau GmbH

| HFM 706 Lambda Large |

| Standards |

ASTM C518, ISO 8301, JIS A1412, DIN EN 12667, DIN EN 12664 |

| Type |

Large bench top device with optional mobile metal base frame |

Thermal

conductivity

range |

0.001 to 0.5 W/(m·K)**

Performance data:

- Accuracy: ± 1% to 2%

- Repeatability: ± 0.25%

- Reproducibility: ± 0.5%

→ All performance data is verified with NIST SRM 1450 D (thickness 25 mm)

|

| Plate temperature range |

-20 °C to 90 °C |

| Air-tight system |

Sample compartment with possibility to introduce purge gas |

Metering area heat

flux transducer |

254 mm x 254 mm |

| Chiller system |

External; constant temperature setpoint over plate temperature range |

| Plate temperature control |

Peltier system |

| Plate motion |

Motorized |

Plate

thermocouples |

Three thermocouples on each plate, type K (two extra thermocouples with instrumentation kit) |

Thermocouple

resolution |

± 0.01 °C |

Number of

setpoints |

Up to 99 |

Specimen

sizes (max.) |

611 mm x 611 mm x 200 mm |

Variable load/

contact force |

0 to 1900 N (5 kPa on 611 x 611 mm2

Force-controlled adjustment of the contact force or the desired thickness, and thus density, of compressible materials |

Thickness

determination |

- Automatic measurement of mean sample thickness

- Four-corner thickness determination via inclinometer

- Compliance to non-parallel specimen surfaces

|

Software

features |

- SmartMode (incl. AutoCalibration, report generation, data export, wizards, user methods, predefined user definable parameters, user-defined parameters, etc.)

- Measurement History Report

- Enhanced Export Settings

- Storage and restoration of calibration and measurement files

- λ90/90 Report

- Plot of plate/mean temperatures and thermal conductivity values

- Monitoring of heat flux transducer signal

|

** Please note: In the very low thermal conductivity range, accuracy of Lambda (λ) values can be limited.