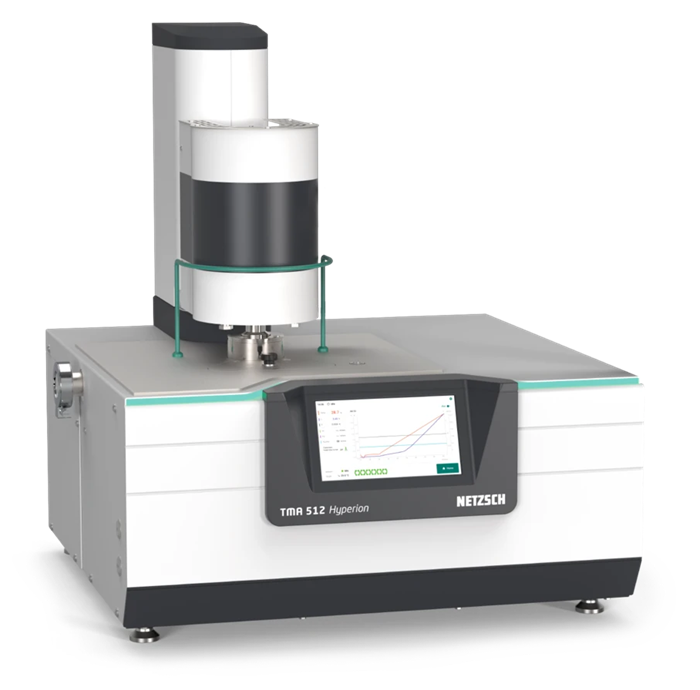

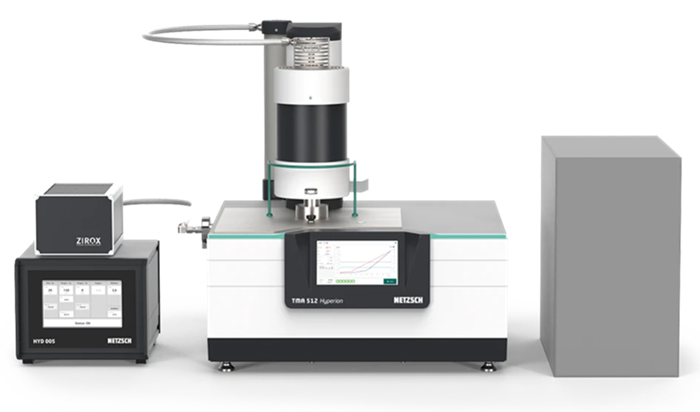

The TMA 512 Hyperion® Select can detect even the smallest dimensional changes to provide the most accurate material insights.

- Nanometer-level precision with advanced LVDT technology: At the core of the TMA 512 Hyperion® is a highly sensitive LVDT sensor capable of detecting length changes at the nanometer scale, with a remarkable digital resolution of 0.125 nm. This ultra-precise detection ensures exceptional accuracy in dimensional change measurements, delivering outstanding results for thermal analysis.

- Measurement status always in view with innovative display and LED status bar: An LED status bar provides clear, at-a-glance information about the current measurement, even from across the lab. The user-friendly touchscreen display allows easy control and real-time monitoring, seamlessly integrated with Proteus® software for fast setup and efficient measurement management.

- Flexible temperature and atmosphere control in a vacuum-tight TMA system: Interchangeable furnaces cover a wide temperature range - from –70 °C to 1500 °C in the Select version (optionally up to 1600 °C). The system also supports various gas atmospheres. Models equipped with two furnaces allow rapid changeover to meet different testing requirements.

- Force Modulation: Digitally programmable force or displacement control up to 3 N is available, with linear or stepwise force alteration and continuous force modulation. This enables precise characterization of viscoelastic properties such as relaxation, creep, and strain/stress.

- Hydrogen research: Performs measurements in atmospheres containing up to 100 % hydrogen with maximum safety.

- Seamless instrument compatibility: Furnaces for the TMA 512 Hyperion® are fully compatible with other NETZSCH thermal analyzers, including the STA 509 Jupiter® and DSC 500 Pegasus®, ensuring smooth integration into multi-instrument laboratory setups.

Image Credit: NETZSCH-Gerätebau GmbH

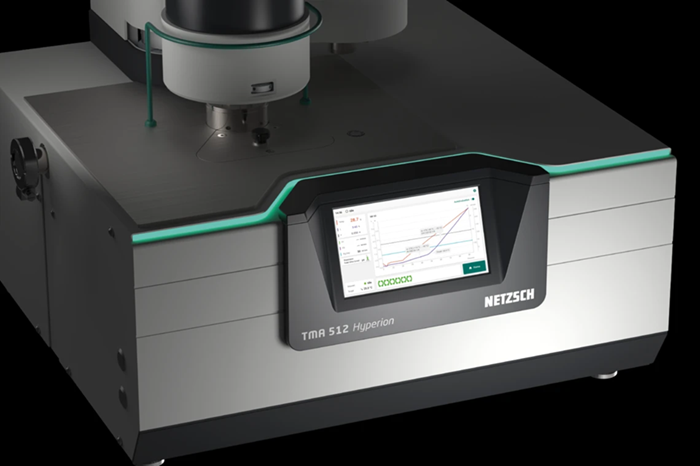

Intuitive Monitoring

The TMA 512 Hyperion® features an LED status bar that clearly indicates instrument status with easily visible color codes, even from a distance. Its integrated touch display offers intuitive control, enabling users to adjust measurement settings quickly and effortlessly.

LED Status Bar and Color Display. Image Credit: NETZSCH-Gerätebau GmbH

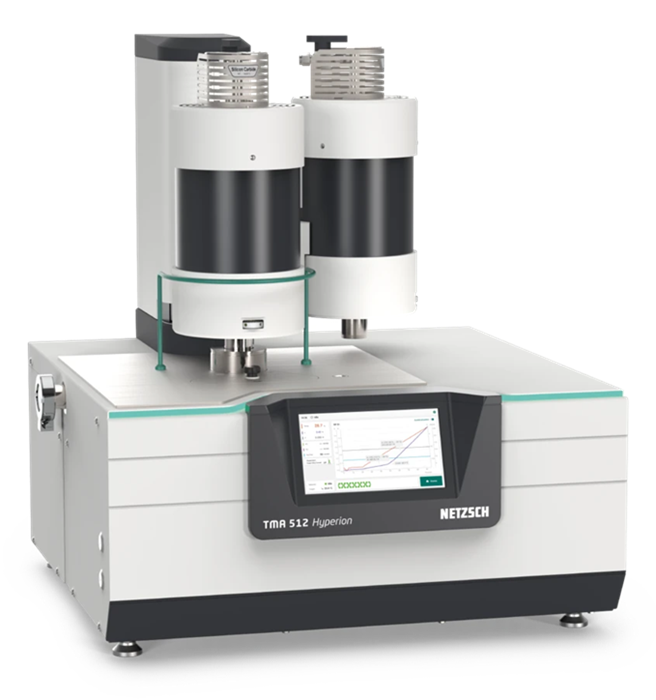

TMA 512 Hyperion® Supreme

- Nanometer-level precision with advanced LVDT technology: At the core of the TMA 512 Hyperion® is a highly sensitive LVDT sensor capable of measuring length changes at the nanometer scale, with a remarkable digital resolution of 0.125 nm. This ultra-high precision ensures exceptional accuracy in detecting dimensional changes, delivering outstanding results for thermal analysis.

- Clear measurement status with LED status bar and touchscreen display: An LED status bar provides clear visual feedback on instrument status, easily visible even from a distance. The integrated touchscreen display offers intuitive control and real-time monitoring, seamlessly connected to Proteus® software for fast setup and efficient measurement management.

- Flexible temperature and atmosphere control in a vacuum-tight system: Interchangeable furnaces support a wide temperature range, from –70 °C to 1500 °C in the Select version (optionally up to 1600 °C). The system can also operate under various gas atmospheres, and models with two furnaces allow rapid changeover to meet diverse testing requirements.

- Advanced force modulation for viscoelastic characterization: Digitally programmable force or displacement control up to 3 N is available, with linear or stepwise force alteration and continuous force modulation. This enables precise determination of viscoelastic properties, including relaxation, creep, and stress/strain.

- Hydrogen research capability: Performs measurements in atmospheres containing up to 100 % hydrogen with maximum operational safety.

- Seamless instrument compatibility: Furnaces for the TMA 512 Hyperion® are fully compatible with other NETZSCH thermal analyzers, such as the STA 509 Jupiter® and DSC 500 Pegasus®, enabling easy integration into multi-instrument laboratory setups.

Image Credit: NETZSCH-Gerätebau GmbH

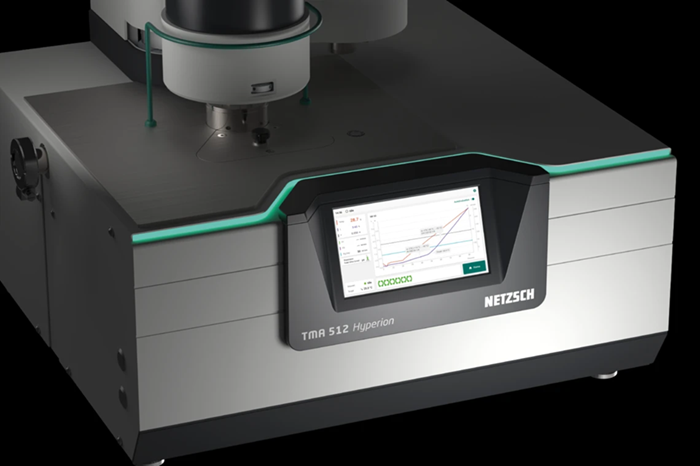

Instant Information at a Glance

The TMA 512 Hyperion® features an LED status bar that uses clear color indicators to show the instrument’s status at a glance. Its integrated touch display provides straightforward, uninterrupted control over measurements, enabling users to adjust settings quickly and easily.

LED Status Bar and Color Display. Image Credit: NETZSCH-Gerätebau GmbH

Providing Real-World Conditions for TMA Measurements

Experience accurate, reliable simulation of environmental influences to take your material analysis to the next level. The TMA 512 Hyperion® Supreme offers advanced furnaces and humidity control systems designed to precisely replicate real-world humidity and temperature conditions.

- Water-vapor furnace: Operates from room temperature up to 1250 °C and connects seamlessly to a humidity or steam generator. This allows precise control of water vapor for high-temperature testing.

- Copper furnace: Ideal for temperatures between –150 °C and 500 °C, it supports in-situ drying and controlled humidity environments from 0 °C to 100 °C. For added convenience, a built-in humidity calculator is available in the TMA Proteus® software.

Humidity generator connected to the TMA 512 Hyperion®. Image Credit: NETZSCH-Gerätebau GmbH

H2Secure: The Ultimate Safety Solution for Hydrogen Testing

NETZSCH’s innovative H2Secure concept for the TMA 512 Hyperion® delivers a comprehensive, safe, and flexible solution for testing materials in environments with varying hydrogen concentrations. Its robust, built-in safety protocol allows you to perform complex oxidation–reduction cycles with confidence, providing precise insights into reaction kinetics and material behavior, without compromising safety.

With H2Secure, you can count on cutting-edge performance and complete peace of mind in hydrogen testing.

TMA 512 Hyperion® connected to H2Secure for measurements under hydrogen. Image Credit: NETZSCH-Gerätebau GmbH

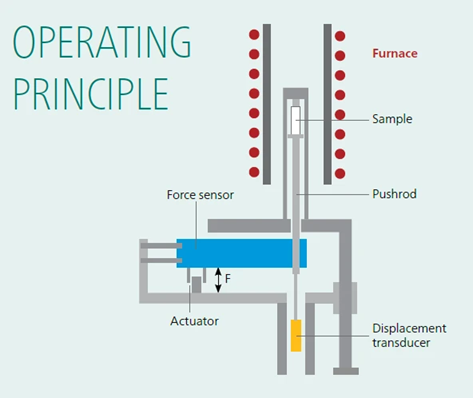

The Determination of Dimensional Changes with TMA

Thermomechanical Analysis (TMA) is a technique used to measure dimensional changes in solids, liquids, or pasty materials as a function of temperature and/or time under a defined mechanical force (DIN 51005, ASTM E 831, ASTM D696, ASTM D3386, ISO 11359 – Parts 1 to 3). It is closely related to dilatometry, which measures length changes in specimens under negligible load (DIN 51045).

In TMA, a defined force is applied, and various measurement modes - such as compression, tension, or bending - can be used to gain detailed insight into material behavior. TMA can detect thermal expansion and transitions, including phase changes, softening, and sintering (the process of forming a mechanically strong body from ceramic or metallic powder).

This method is widely used in research, development, and quality control, and is essential for analyzing materials such as plastics, elastomers, composites, adhesives, films, fibers, ceramics, glass, and metals. TMA helps engineers optimize material performance and ensure long-term product reliability.

Image Credit: NETZSCH-Gerätebau GmbH

Specifications

TMA 512 Hyperion® Select. Source: NETZSCH-Gerätebau GmbH

| |

|

| Temperature range |

-70 °C to 1500 °C/optional 1600 °C |

| Furnaces |

- IC furnace for use with intracooler

- SiC furnace

|

| Specimen dimensions |

Sample length max.: 30 mm

- Expansion: Ø 12 mm, Ø 10mm, Ø 8mm

- 3-Point Bending: Length: 24 mm, width: 5 mm, free bending length: 5, 10, 20 mm

- Tension: Width: 6/8 mm, thickness: 1 mm

|

| Temperature accuracy / precision / resolution |

1 K / 0.1 K / 0.001 K |

| Force range (load at the sample) |

10 mN … 3 N (valid for compressive and tensile force depending on the sample holder) |

| Heating / Cooling Rate |

0.001 K/min to 50 K/min |

| Gas flow control |

3-way switch

optional 1-way/3-way/4-way MFC |

| Force and displacement |

Simultaneous measurement of force and displacement signal |

| Force resolution |

< 0.01 mN |

TMA 512 Hyperion® Supreme. Source: NETZSCH-Gerätebau GmbH

| |

|

| Temperature range |

-150 °C to 1600 °C |

| Furnaces |

- IC furnace for use with intracooler

- SiC furnace

- Steel

- Copper (for humidity)

- Water vapor

|

| Sample dimensions |

Sample length max.: 30 mm

- Expansion: Ø 12 mm, Ø 10mm, Ø 8mm

- 3-Point Bending: Length: 24 mm, width: 5 mm, free bending length: 5, 10, 20 mm

- Tension: Width: 6/8 mm, thickness: 1 mm

|

| Heating/cooling rate |

0.001 K/min to 50 K/min |

| Force range (load at the sample) |

10 mN … 4 N (valid for compressive and tensile force depending on the sample holder) |

| Heating / Cooling Rate |

0.001 K/min to 50 K/min |

| Gas flow control |

1-fold MFC or

optional 3-way/4-way MFC |

| Force and displacement |

Simultaneous measurement of force and displacement signal |

| Force resolution |

< 0.01 mN |