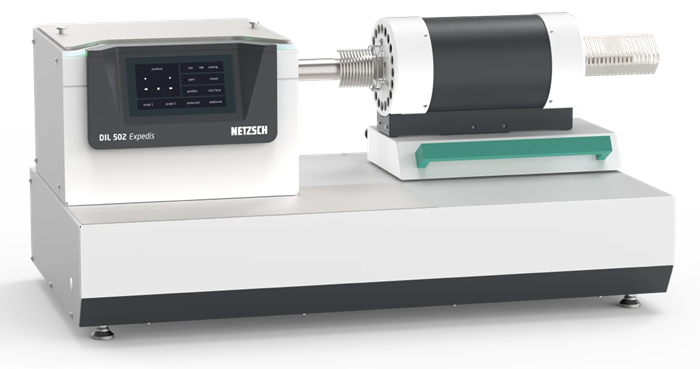

The DIL 502 Expedis® Classic provides the best price/performance ratio for cutting-edge dilatometer technology.

- Wide temperature range: Operates seamlessly from room temperature up to 1600 °C, handling even the most challenging materials with ease.

- Exceptional measurement range and resolution: The NanoEye optoelectronic displacement system offers outstanding linearity and nanometer-level resolution, detecting even the smallest dimensional changes.

- Consistent and reliable results every time: Automatic Specimen Length Detection removes the risk of manual measurement errors by automatically determining the specimen’s initial length before testing.

- High throughput capability: Optional dual furnace and dual measuring system configurations allow multiple samples to be tested simultaneously, accelerating your workflow.

- Maintenance-free operation: Designed for maximum uptime with minimal maintenance, ensuring greater operational efficiency in the lab.

- MultiTouch technology: MultiTouch’s unique, tail-like motion ensures stabilized, repeatable specimen placement, optimizing positioning and improving measurement reliability.

- Compact all-in-one design: Eliminates the need for additional chillers or power units, creating a cleaner, more organized workspace - ideal for demanding industrial environments.

Image Credit: NETZSCH-Gerätebau GmbH

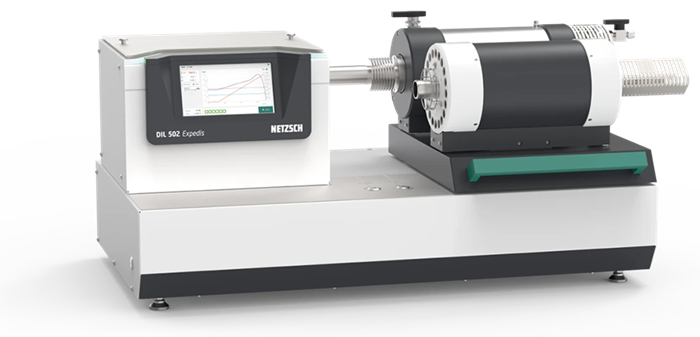

DIL 502 Expedis® Select

The DIL 502 Expedis® Select is the ultimate dilatometer for advanced industrial research and contract laboratories. This versatile system features a vacuum-tight dual furnace design, enabling an extensive temperature range of –180 °C to 2000 °C in a single instrument for maximum efficiency.

- Select the ideal furnace for your application: For ultra-low temperatures down to –180 °C, choose the copper furnace. The dual furnace configuration lets you add a graphite furnace with a range from room temperature up to 2000 °C in the Select version. Together, they cover the complete range of –180 °C to 2000 °C, meeting the needs of most applications.

- Consistent, reliable results: Automatic Specimen Length Detection eliminates manual measurement errors by automatically detecting the specimen’s initial length before testing.

- Stable sample positioning with MultiTouch technology: MultiTouch’s unique, tail-like motion ensures stabilized and repeatable specimen placement, optimizing positioning and improving measurement reliability.

- Adjustable thermocouple positioning: Easily accommodate specimens of varying lengths with an adjustable thermocouple guided by a flexible rod, allowing precise placement without bending or damage.

- AutoVac for inert atmosphere testing: The optional AutoVac system enables rapid evacuation and gas refilling for measurements under pure inert atmospheres, which is ideal for analyzing oxidation-sensitive materials.

- Compact all-in-one design: Eliminates the need for additional chillers or power units, creating a clutter-free workspace perfectly suited for high-demand industrial environments.

Image Credit: NETZSCH-Gerätebau GmbH

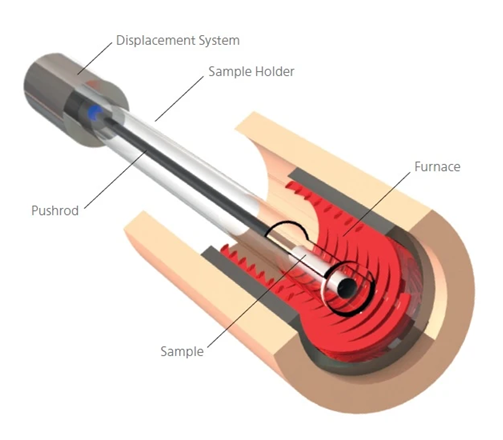

The Method for Determination of Dimensional Changes

Pushrod Dilatometry is a technique used to measure how a material’s dimensions change as it is heated or cooled over time. During testing, the sample is placed in a furnace with temperature precisely controlled according to a programmed profile. As the temperature changes, the sample expands or contracts.

A pushrod in contact with the sample moves to follow these dimensional changes. Its movement is measured with high precision, allowing accurate tracking of the sample’s length variation.

This method enables the characterization of several fundamental phenomena, including:

- Thermal expansion or shrinkage

- Sintering of ceramics or metals

- Glass transition and softening point of polymers

- Phase transitions

Such information helps scientists and engineers understand how materials behave at different temperatures - critical for designing products that perform reliably under real-world conditions.

View inside the DIL 502 Expedis® furnace. Image Credit: NETZSCH-Gerätebau GmbH

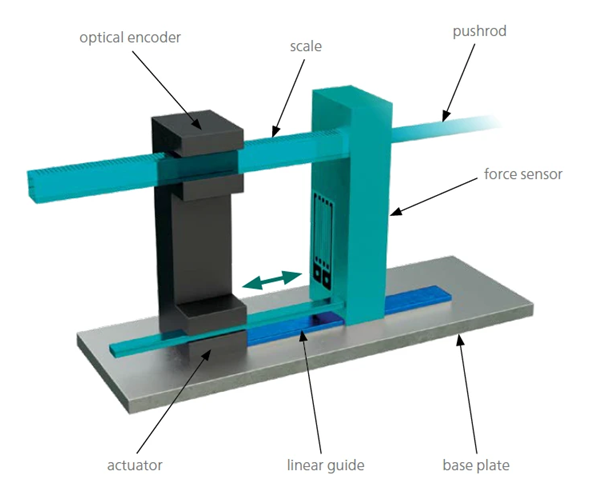

The Revolutionary Precision of the NanoEye Displacement System

In traditional dilatometry, achieving higher resolution often means compromising measurement range, and vice versa. The NanoEye system eliminates this trade-off entirely. Delivering both ultra-high resolution and an exceptionally wide measurement range, NanoEye sets a new benchmark in thermal expansion analysis.

At the core of the DIL 502 Expedis® is the advanced optoelectronic NanoEye displacement system. This technology ensures perfect linearity in every measurement, consistently outperforming conventional dilatometry systems. A linear encoder converts position into a digital signal with unwavering accuracy, regardless of temperature or sample length.

Image Credit: NETZSCH-Gerätebau GmbH

Maximizing Lab Efficiency with the Energy-Smart DIL 502 Expedis®

Today, the focus on energy efficiency is stronger than ever, with industries and academia worldwide exploring new ways to conserve resources and adopt sustainable alternatives.

The DIL 502 Expedis® sets a new standard for smart energy use. By replacing energy-intensive water-cycle thermostats with advanced electronic temperature control, it maintains exceptional stability while dramatically reducing energy consumption and heat waste. The result is highly accurate thermal expansion measurements with a smaller environmental footprint.

Customizable Idle and Eco modes further improve efficiency by intelligently reducing power use when the instrument is idle. This not only lowers CO2 emissions but also keeps your lab operating sustainably, without sacrificing performance or ease of use.

Specifications

DIL 502 Expedis® Classic. Source: NETZSCH-Gerätebau GmbH

| |

|

| Temperature range |

RT to 1600 °C |

| Furnaces |

- Fused Silica

- Silicon Carbide (fast cooling)

|

| Specimen dimensions |

Length: Max. 52 mm

- Ø 12 mm standard (optional Ø 19 mm max.)

- Ø 8 mm in dual specimen holder system

|

| Heating rate |

0.001 … 50 K/min |

| Gas flow control |

1-way switch

optional 3-way switch, MFC |

| Measuring range |

±5000 μm |

| Force range (load at the sample) |

10 mN … 3 N

(compressive and tensile force depending on sample holder) |

| ΔL Resolution |

2 nm |

| Force resolution |

0.001 N |

DIL 502 Expedis® Select. Source: NETZSCH-Gerätebau GmbH

| |

|

| Temperature range |

-180 °C to 2000 °C |

| Furnaces |

- Fused Silica

- Silicon Carbide (fast cooling)

- Copper

- Stainless Steel

- Rhodium Graphite (2000 °C)

|

| Specimen dimensions |

Length: Max. 52 mm

- (Graphite furnace: 25 mm)

- Ø 12 mm standard (optional Ø 19 mm max.)

- Ø 8 mm in dual specimen holder system

|

| Heating rate |

- 0.001 … 50 K/min

- Graphite: 0.001 … 100 K/min

|

| Gas flow control |

1-way MFC or

optional 3-way/4-way MFC |

| Measuring range |

±10000 μm |

| Force range (load at the sample) |

10 mN … 3 N

(compressive and tensile force depending on sample holder) |

| ΔL Resolution |

1 nm |

| Force resolution |

0.001 N |