The AutoPhaseMap module in AZtecEnergy, the EDS software from Oxford Instruments, detects areas of different characteristic chemistry from X-ray map data, and identifies the composition, constituent elements, area, and distribution of each of these phases or areas. This article discusses the application of the AutoPhaseMap module in the characterization of an aluminium alloy and its inter-metallic phases.

Automatic Phase Mapping and Detection

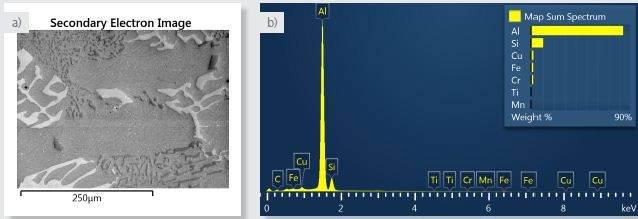

Aluminium alloys generally consist of intra- and inter-grain metallic inclusions. Figure 1a shows an SE image of a representative region of an aluminium alloy, suggesting the presence of at least two of these phases. Figure 2b depicts a spectrum acquired from this area, revealing the existence of a number of minor elements such as silicon, manganese, iron, and copper.

Figure 1. a) Secondary electron image of area analysed. b) spectrum of the area analysed from the sum of all X-ray data collected during X-ray SmartMap acquisition.

Table 1 summarizes the conditions under which an X-ray SmartMap was acquired from an area of the sample. A high map resolution and relatively low accelerating voltage were selected because of the comparatively small size of some of the phases. The X-ray maps were employed during acquisition to generate an AutoPhaseMap image (Figure 2).

Table 1. Acquisition Parameters for SmartMap Acquisition

| SEM Type |

W Gun |

| Acquisition Time (s) |

2360 |

| Acquisition Rate (cps) |

26000 |

| Accelerating Voltage (kV) |

10 |

| Map resolution |

1024x768 |

| No of pixels |

786423 |

| Counts per pixel |

60 |

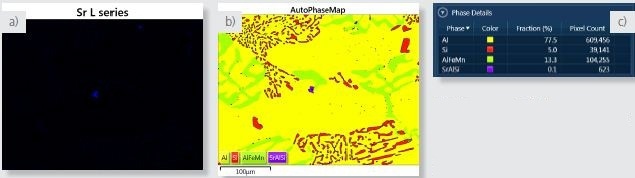

The AutoPhaseMap image not only ascertained the existence of three phases that include the two inter-metallic phases, but also revealed a small area without identifying any phase.

The reconstruction of a spectrum from this small area showed a further constituent element, strontium, which was not discovered earlier because of the scarcity of the phase, low kV, and the overlap between Sr L and the rich Si K X-rays.

After the addition of the Sr L X-ray map (Figure 2a), the AutoPhaseMap was reconstructed from this modified X-ray map data (Figure 2b), revealing the microstructure of the sample with the identification of four phases. AutoPhaseMap also provides data on the area fraction of each phase (Figure 2c).

Figure 2. a) X-ray map for Sr L b) AutoPhaseMap image calculated from the X-ray maps shows the distribution of the phases in the sample. c) Phase details page summarizes the phases found and their relative abundance.

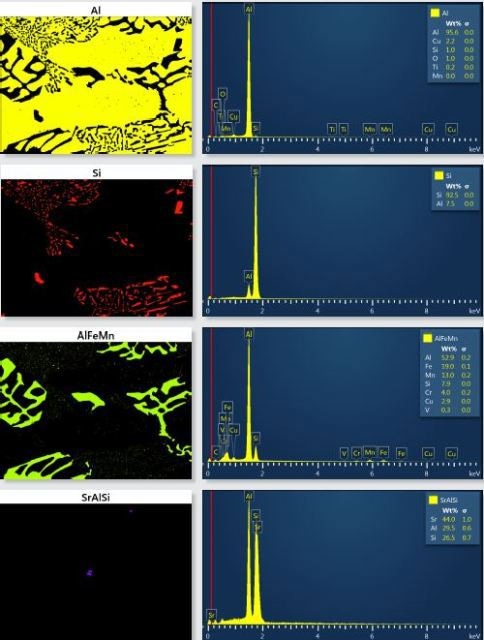

Furthermore, for each phase, the AutoPhaseMap software displays a phase image delineating the phase distribution; a spectrum constructed by summing the pixels determined corresponding to that phase; and a quantitative result for each phase providing the average phase composition. Figure 3 shows the results for the identified phases.

Figure 3. AutoPhaseMap results for the four phases identified in the aluminium alloy sample

Conclusion

AutoPhaseMap identifies the phases present in a sample using the X-ray maps calculated from an X-ray SmartMap. The AutoPhaseMap data is computed within seconds, even for a large dataset consisting of more than 700,000 pixels.

This enables AutoPhaseMap to be applied in real-time as part of the specimen analysis besides being used for analyzing the phases in the sample. In this example, the AutoPhaseMap module helped identifying a new constituent element and an additional phase.

This information has been sourced, reviewed and adapted from materials provided by Oxford Instruments NanoAnalysis.

For more information on this source, please visit Oxford Instruments NanoAnalysis.