G.T. Michelli Co. offers systems and products in the force measurement field as well as support services for maintaining the applications provided in a myriad of markets and industries, ranging from biomedical facilities to petrochemical manufacturing.

The Requirement

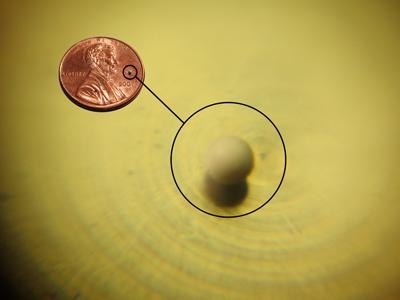

A customer of G.T. Michelli Co. required a new system to optimize the accuracy and precision of compressive crush force measurements for its spherical alumina products with a diameter of 0.7mm (Figure 1). These high-purity spheres are employed in peptization processes or as efficiency-improving catalysts in the chemical industry. Hence, they need to deliver consistent performance under extreme conditions. The customer has preset conditions for the crush failure characteristics required to be met. However, the existing manually-operated stand and gauge system was not able to deliver the required level of confidence.

Figure 1. High-purity pharmaceutical alumina sphere

Mecmesin’s Solution

The alumina product samples were tested by Mecmesin. A video footage of the process was created by Mecmesin along with an in-depth report covering the measured force characteristics output from the proposed computer-controlled system. Using this data, the required solution was adopted by G.T. Michelli’s end customer.

The system consists of a single-column Mecmesin test stand 2.5kN intelligent loadcell fitted with a self-leveling 50-mm diameter upper compression plate and a self-leveling 70-mm diameter base compression plate, exerting a top load on an individual sphere until it breaks down (Figure 2). The force exerted on the sphere under load is read as a real-time graph, recording the first-peak failure value as the critical data. The sample testing is performed under laboratory conditions and the entire process is automated by the connected PC running Emperor™ software through the custom-made test program created by Mecmesin engineers.

Figure 2. A single sphere compressed to failure

Conclusion

Human error or inconsistency is eliminated using the Emperor™ software, a crucial advantage of the new solution that provides particular value to G.T. Michelli’s end customer. In addition, the Mecmesin test stand’s fixed compression plates do not require any adjustments, and the upper and lower travel limit switches of the crosshead secure the loadcell from overload damage. These are the other advantages of the new solution over earlier system.

Note: The MultiTest test stand and Emperor software has been superseded by the OmniTest universal testing machine and VectorPro software.

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.