Viscometers are often used to characterize food and drink products, and they provide straightforward and simple measurements for quality control. Viscometers are also widely employed in formulation, but here simple viscosity measurements are often unable to provide the level of detail required to describe the properties of complex non-Newtonian formulations. Hence, rheology has far more to offer compared to simple viscosity measurements for formulation measurements.

Image Credits: Trong Nguyen/shutterstock.com

Using a rheometer instead of a viscometer offers access to an extended range of test capabilities that can be applied to refine and accelerate the development of a formulation to a more successful commercial solution. Traditional barriers of exploiting rheology's full potential have been a lack of understanding about which test to apply and how to interpret the data that results.

Recent developments in the design and functionality of rheometers provide solutions to these issues, making detailed, informative rheological studies more accessible. This article discusses the potential rewards of exploiting these developments.

A More Complete Flow Curve – Extending Viscosity Measurements

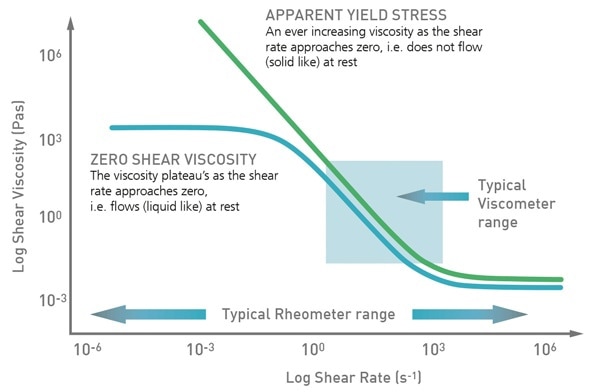

A defining principle of rheological characterization is that the measurement conditions used should reflect the conditions the product will experience during use. A failure to fulfill this condition results in the need for extrapolation beyond the measurement range, causing problems as shown in Figure 1.

The blue shaded window represents a typical measurement range for a rotational viscometer (Bohlin Visco 88, Malvern Panalytical), clearly highlighting the inability of a viscometer to completely acquire the viscosity profile of a sample, especially at the extremes of the shear rate range.

Figure 1. With a rotational rheometer it is possible to extend the flow curve across a much wider shear rate range to understand how a product will behave under all the conditions encountered during routine use.

In quality control, this limitation may be less significant because verifying consistency by testing against a single point specification within the accessible measurement range may be sufficient. However, this is not the same for formulation, where understanding how the material behaves under various conditions helps to ensure optimal performance under all situations.

For instance, the shear rate experienced by a product stored on a shelf and subjected only to the force of gravity is very low (typically below 10- 3s-1). It is possible to correlate the rheological behavior measured under these conditions with product stability, especially when the product is an emulsion or a suspension.

Rotational Rheometers

A product that appears solid-like under such conditions (apparent yield stress) will show more resistance to settling compared to a product that appears more liquid-like and has a low zero shear viscosity. Therefore, the ability to measure in the low shear rate region can directly help to develop products with target stability. Measuring up into the higher shear rate range can be equally valuable for evaluating dispensing characteristics when shear rates may be much higher.

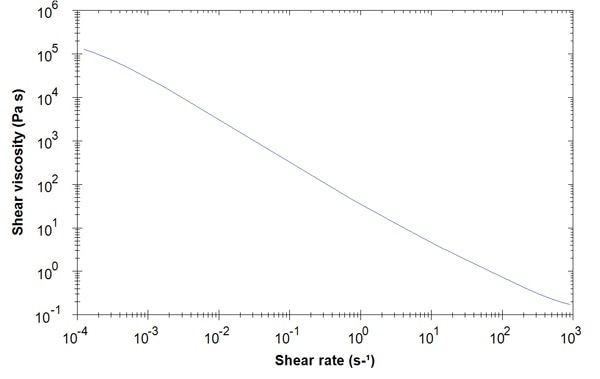

Modern rotational rheometers provide the torque and radial displacement sensitivity to perform measurements down to these extremely low shear rates and stresses. They also have the dynamic range and gap accuracy to access very high shear rates and stresses, as shown in Figure 2.

The data for ketchup measured over seven decades of shear rate and covering a viscosity range of 0.1 – 100,000 Pas is presented in Figure 2. The top left hand corner of the chart could only be accessed with a rotational viscometer.

Figure 2. A flow curve for Ketchup measured over seven decades of shear rate using a rotational a rheometer (Kinexus, Malvern Panalytical).

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.