This article briefly describes the wide range of seals and products available from Omniseal Solutions™ and shows how they are used in the Aerospace, Oil & Gas, Automotive, Life Sciences and Industrial industries.

Omniseal Solutions™: Aerospace

Precise Fit

APU

- High linear speed: > 15 m/seconds

- Seal at various temperature during flight cycle: -54 °C / +177 °C

- Needs to be compatible with aerospace oil

Jet Engine

- No thermal aging: constant performance

- Seal at various temperature during flight cycle: -54 °C / +350 °C

- Wear resistant to fretting

Landing Gear

- Seal at various temperature during flight cycle: -54 °C / +80 °C

- Needs to scrape dust, ice and other polluting agents

- Needs to be compatible with all hydraulic aerospace fluids

Lifetime Confidence

APU

- Needs to perform during 50,000 hours of flight

Jet Engine

- Needs to perform during 20,000 hours

Landing Gear

- Needs to perform during more than 20,000 flight cycles

Omniseal Solutions™: Oil and Gas

Lifetime Confidence

FPSO Turret Swivels

- Manufactured to precise tolerances up to 1.5 meter diameter

- Pressures up 10,000 psi / 690 bar

- Low wear seal capable of millions of cycles/year

- 30 years lifetime

Subsea Production & Pipeline Valves

- Qualified up to 1,200 mechanical cycles

- Pressures up 20,000 psi / 1,380 bar

- 30 years lifetime

Precise Fit

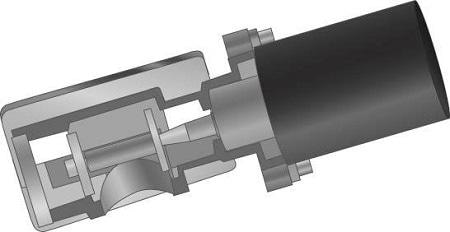

Subsea Hydraulic Couplers

- Manufactured to precise tolerances

- Pressures up 20,000 psi / 1,380 bar

- Compatible with methanol, hydrocarbon-based fluids

- 30 years lifetime

Cryogenic Valves for LNG Carriers

- Manufactured to precise tolerances

- Cryogenic operating temperature -196 °C

- No leakage allowed

- 5 years lifetime

Omniseal Solutions™: Automotive

Precise Fit

Transmission (Seal Rings)

- Pressures up to 8 MPa

- Speeds up to 7,500 rpm

- Optimized designs for controlled and constant leakage and friction

Transmission (Thrust Washers)

- Pressures up to 11 MPa

- Speeds up to 11 m/s

- Optimized designs to minimize space

- 80% friction reduction when compared to traditional tribological grades

Lifetime Confidence

Emission Control (Components)

- High chemical resistance

- Low and constant leakage: < 10 ml/minute over lifetime

- Constant low friction: < 0.5 N over lifetime

Brake System (Components)

- Intelligent brake systems for the future

- Key partner to international market leaders for critical parts

- Increased safety over vehicle lifetime

Omniseal Solutions™: Life Sciences

Precise Fit

Liquid Chromatography – HPLC/UHPLC

- Temperatures up to 176 °F / 80 °C

- Pressures up 18,000 psi / 1,240 bar

- Proprietary material validated by testing

- Manufactured to precise tolerances

- Low wear seal capable of millions of cycles/year

- Compatible with a wide range of harsh solvents

Surgical Tools

- Temperatures up to 266 °F / 130 °C

- Dry running up to 40,00 psi

- Precision tolerances

- Withstands steam autoclaving

Lifetime Confidence

Portable Oxygen Concentrator

- Seals offer up to 15,000 hours of service life

- Reciprocating up to 3,000 cycles per minute

- Dry running part acts as seal and bearing

Blood Analyzer

- Validated 1 million cycle life

- Dry running/reciprocating

- Extend maintenance cycle x 3

Omniseal Solutions™: Industrial

Lifetime Confidence

Commercial HVAC Recovery Pump

- Pressures up to 2.7 MPa

- Speeds up to 5,000 rpm

- Seals will last lifetime of pump

- Compatible with a wide variety of refrigerants and oils

Chemical Diaphragm Pumps

- Most important component of pump

- High chemical resistance

- Designed for long life

Precise Fit

Screw Compressors

- Speeds up to 6,000 rpm

- Temperature from -55 °C / +165 °C

- Pressures from vacuum to 2.7 MPa

- Tight leakage control

- Seals air and oil

- Seal life in excess of 15,000 hours

- Able to run dry

- Reduces warranty claims

This information has been sourced, reviewed and adapted from materials provided by Omniseal Solutions™.

For more information on this source, please visit Omniseal Solutions™.