O-rings of five different kinds were tested using the iNano indentation system from KLA. The data on each is displayed in Table 1. A flat cylindrical punch (D= 100 µm) was used to measure the complex modulus of each O-ring, at room temperature. The method was “Dynamic Flat Punch Complex Modulus,” in which the punch was pressed down until it made complete contact with the O-ring. At this point, the iNano was employed to find the storage modulus (E’) and the loss modulus (E”) using a range of oscillatory frequencies between 1 and 200 Hz.

Table 1. O-ring sample information

| ID |

Product Name |

Storage Modulus at 35 Hz (MPa) |

Loss Modulus at 35 Hz (MPa) |

Loss factor at 35 Hz |

| 1 |

Oil-Resistant Buna-N Multipurpose O-Ring Size 210 |

34.40±0.93 |

6.11±0.13 |

0.18±0.001 |

| 2 |

Super-Resilient High-Temperature Silicon Ring |

18.53±0.55 |

1.16±0.04 |

0.06±0.001 |

| 3 |

Chemical-Resistant Multipurpose O-Ring |

14.93±0.65 |

7.42±0.32 |

0.50±0.003 |

| 4 |

Steam-Resistant EPDM O-Ring |

47.33±0.68 |

6.06±0.07 |

0.13±0.003 |

| 5 |

Oil-Resistant Buna-N Multipurpose O-Ring Size 202 |

27.96±0.62 |

5.38±0.07 |

0.19±0.003 |

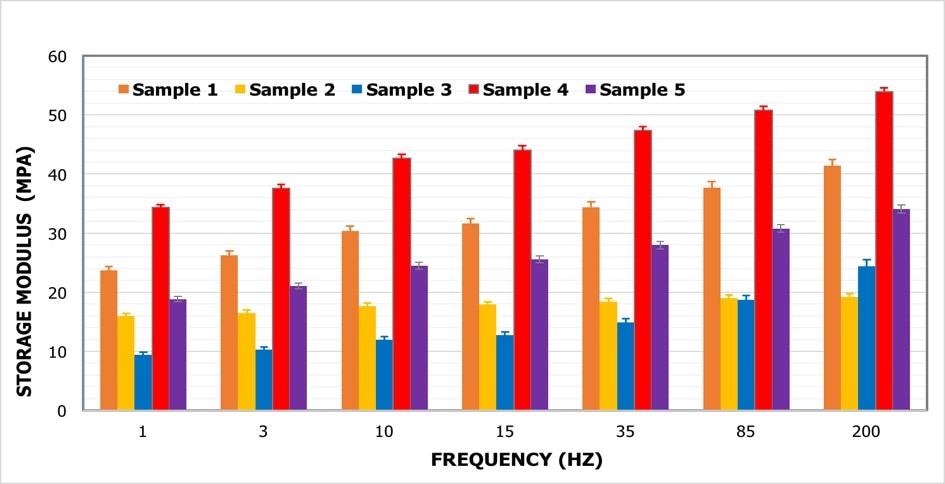

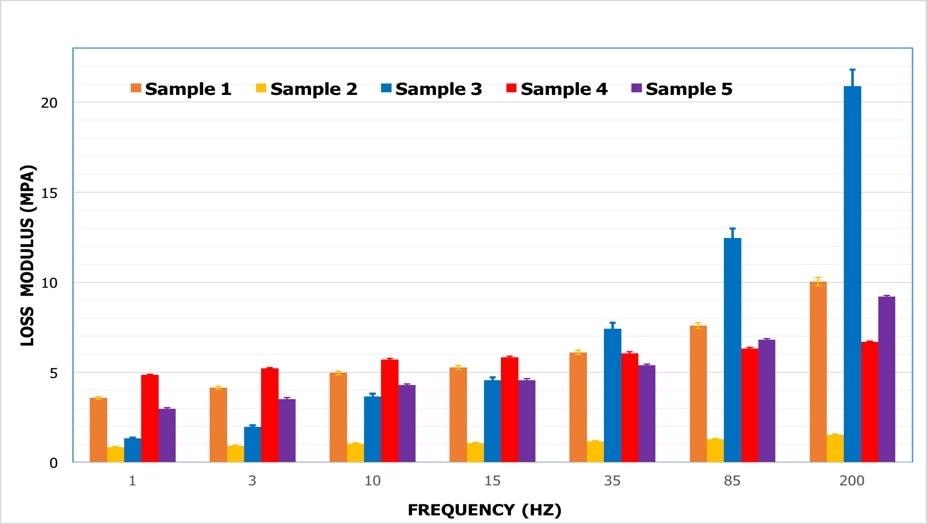

The iNano instrumented indentation system can assess the same parameters as the more traditional DMA, but the measurements are more focal, and the results are faster and easier to obtain. For instance, Figure 1 shows the storage modulus (also called elasticity) and Figure 2 the loss modulus (or damping) in relation to frequency variations. It is obvious that mechanical properties are quite different between the O-rings tested, which means the choice of ring should be suited to the application in mind. For instance, the silicon O-ring showed properties which did not vary much with the frequency of oscillation, but the others were frequency-dependent, especially the sample 3 chemical-resistant O-ring.

Figure 1. Storage modulus of o-ring samples as measured by oscillatory indentation

Figure 2. Loss modulus of o-ring samples as measured by oscillatory indentation

This information has been sourced, reviewed and adapted from materials provided by Nanomechanics, Inc., a KLA-Tencor company.

For more information on this source, please visit KLA.