The SensoSCAN software has a clear, intuitive and user-friendly interface, which drives the systems. A unique user experience is delivered, as the user is guided through the 3D environment.

Sample Navigation

The user can inspect the sample during measurement preparation, check measurement positions before acquisition as well as assist in the automation procedure, all through an overview tool. This ameliorates the experience of working with high magnification, as users will know where they are at every moment.

Auto 3D Function

With the selection of 3D Auto function, SensoSCAN software can automatically determine the correct illumination and the appropriate measurement range, and subsequently perform the chosen measurement type. It therefore requires just a few seconds to obtain a high-quality result.

Analysis and Reporting

The user can also create analysis templates, in order to apply pre-determined filter and

operator configurations to repeated measurements. Finally, an accurate and well-structured report for each measurement is provided, displaying the 3D data, a 2D profile and all the ISO parameters.

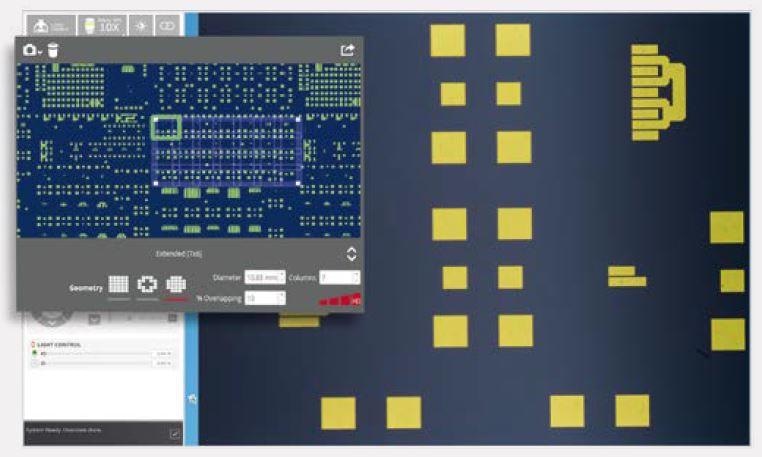

Extended Measurements Module

The user can easily define the measurement layout on the surface by means of the overview image within SensoSCAN’s extended measurements module. Rectangular, circular, or ring areas of interest can be highlighted with the automatic crop function, with the possibility of including wide areas up to 500 million pixels. Several scanning strategies are available, such as autofocusing on each field, or focussing tracking to minimize vertical scanning range.

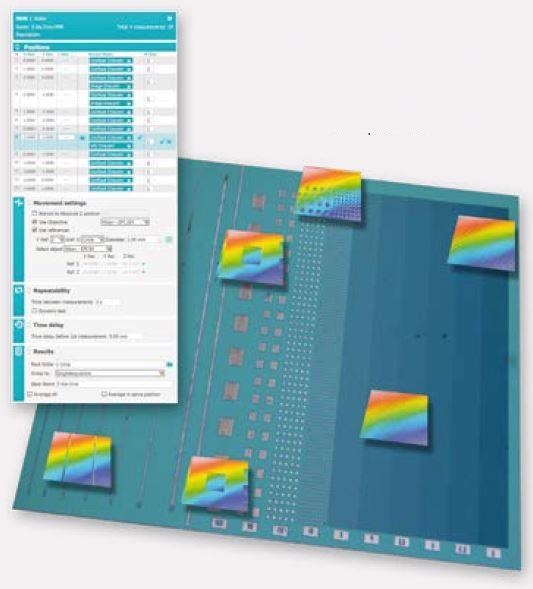

Automating Procedures Module

The Recipes tool - an easily customizable tool for creating quality control procedures - allows the user to obtain automated measurements. This tool is ideal for Quality Control inspection, as the profile manager tool, sample identification, data exportation and ‘pass or fail’ criteria render the procedure-defining process extremely simple.

Multiple Powerful Acquisition Settings

It is possible to adapt numerous acquisition parameters to best suit the intended measurement. For example, the acquisition time can be reduced by various autofocus settings, the illumination of complex 3D structures is helped by HDR function and the opportunity to optimize the acquisition for varying 3D surfaces is provided by selectable Z-scan options.

Powerful Advanced Analysis Software

SensoVIEW

SensoVIEW is the ideal software for a wide scope of analysis tasks. Advanced software packages are additionally available for applications requiring a more complete analysis suite, such as SensoMAP and SensoPRO.

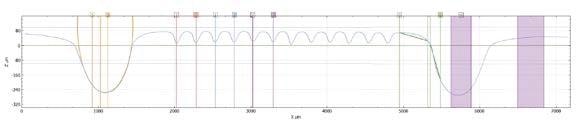

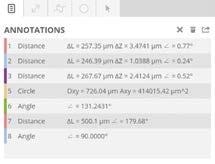

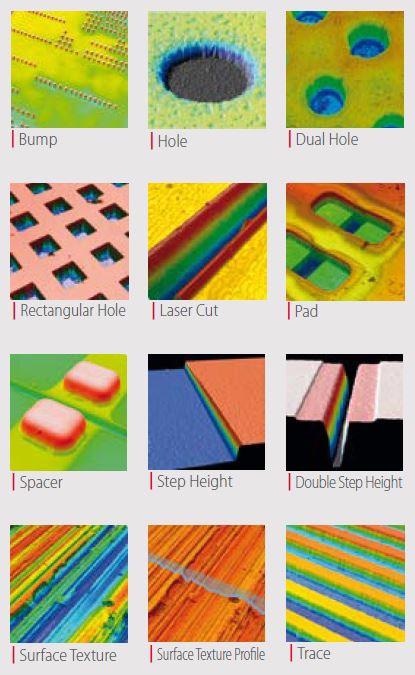

Interactive Analysis Tools

Multiple scaling, display and render options are provided by 3D and 2D interactive views, as well as a comprehensive suite of tools for preliminary examination and analysis of 3D or 2D measurements. Angles, distances, diameters and critical dimensions can be measured, and features can be highlighted with new annotation tools.

SensoPRO

Fast quality control in a production line has never been easier. With SensoPRO, the production line operator only needs to load the sample and follow guided instructions. A high degree of flexibility is provided by plug-in-based data analysis algorithms. New modules are easily customizable to other industry needs.

Sequential Operators

A comprehensive set of operators provides the opportunity to retouch data points, restore non-measurable data, remove form (plane, sphere, polynomial), apply a range of filters and/or generate alternative layers by cropping, subtracting or extracting a profile.

Analysis templates can also be created, in order to apply pre-determined filter and operator configurations to repetitive measurements.

SensoMAP

SensoMAP is a vastly powerful tool for analysis and reporting, based on Mountains technology from Digital Surf, and completely modularly adaptable to customer requirements. Options available include two levels (standard and premium) and several modules (2D, 3D or 4D modules, Advanced Contour, Grains & Particles, Statistics and Stitching).

This information has been sourced, reviewed and adapted from materials provided by Sensofar.

For more information on this source, please visit Sensofar Metrology.