In this interview, AZoM talks to Dr. Robert Keighley, senior staff scientist at SHIMADZU, about spectrophotometer, and the capabilities of the next-generation models available on the market.

Can you give a brief overview of Shimadzu and the markets you serve?

Shimadzu is one of the largest Scientific Instrument manufacturers in the world, with over 12,500 employees. Over 4,000 Shimadzu employees work in R&D to create cutting edge technology, with an ethos that innovation is paramount. Founded in 1875, Shimadzu has continued to grow organically and consists of five primary business units, of which Scientific Instruments is one. Shimadzu has a number of research facilities globally and its products cover a very large range of markets from Academic Research, Pharmaceuticals, Contract Testing, and a vast range of manufacturing markets from Paints and Polymers through to Petrochemical Refining, Automobiles, Plastics, Recycling, Agriculture and many others. Shimadzu aims to provide innovative solutions to real-life problems within these industries.

How does the processing power of programmable circuits effect spectrometers?

The very first Spectrophotometers were made in an era before programable circuits were widely available and therefore had a poor processing power and used manual readings recorded to create a ‘scan’ via a hand-drawn chart. Since then, technology has advanced considerably to instruments which not only scan automatically but also record the data. A parallel advance in display technologies and display drivers allowed the real-time display of spectra during acquisition, whilst faster processors and bigger memory capacity allowed complex interpretation of data (such as derivative spectra) or internal storage of standard calibration curves. Modern spectrophotometers can store file names and unique labels for hundreds or even thousands of spectra, which can be recalled and displayed or exported and printed. Complex relationships can also be calculated between data sets or for deduction of spectral quality.

What are the differences between the processing powers of early spectrometers compared to the spectrometers of today?

As mentioned in the previous question, the very first spectrophotometers had no processing power, and they were based on analog circuits with no memory. All recordings had to be either fully manual or via an analog constant-speed chart. Nowadays, over half a century later, memory storage capacity and processor speed are unrecognizably greater. The highly popular Shimadzu UV-1900i spectrophotometer is fitted with an internal computer controller including a full-color display and a memory capacity of thousands of scans. And that is when the instrument is used standalone, computer control adds even more power and flexibility. There have been many other advances in the speed and precision of control electronics. For instance, the UV-1900i includes a wavelength drive that has an ability to move a grating with precision and repeatability of better than 0.1 nm, at a tracking speed of 29000 nm/min. This motion is not continuous, it involves the drive ‘stopping’ for the read period of both front and rear beams at each wavelength, so the movement is divided into over impressive 4000 stages (stop-move-stop) per second.

What has brought about these differences?

The primary differences between spectrophotometers from 70 years ago and today are the advent of 3 main technologies. Stepper motors have dramatically increased drive precision, removing the need for elaborate mechanical drives with a microswitch or photo-mechanical end-stops. They have also dramatically increased scan speeds by allowing synchronization of a monochromator, source-mirror, second-order filter, and beam chopper drives to tiny fractions of a second. Memory circuits have allowed the control of multiple motors with sub-microsecond co-ordination, whilst also allowing complex programming of the parameters of a scan and any data analysis. Finally, display technology has made it possible for instruments to carry their own fully computer-quality display embedded in the instrument.

What other hardware differences do today’s spectrometers have when compared to early spectrometers?

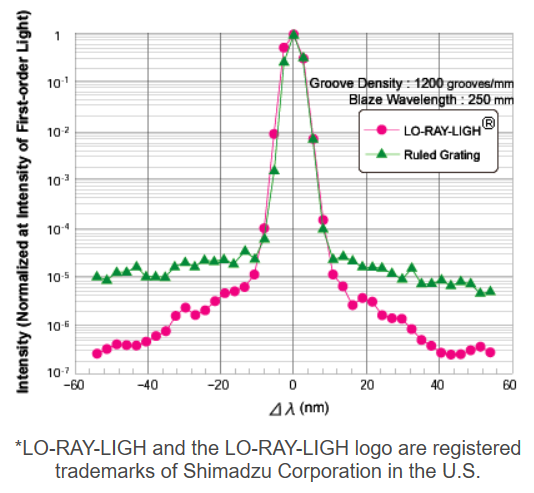

The early spectrophotometers had many design challenges, from requiring heavy castings and expensively machined non-linear prism drives to large hydrogen lamps producing a great amount of heat. This required complex multiple axis adjustment to allow the best precision of alignment. The technological advances moved a long way since then, with new designs no longer using heavy steel or aluminum cast chassis, but modern composites, which can be stiffer than their metal counterparts and have far less thermal expansion reducing the warm-up effects. Modern spectrophotometers no longer use quartz prism but opt for less expensive and more flexible diffraction grating as a monochromator element. These, however, have a limitation of producing “stray light”. The primary technique for removal of stray light is to include a ‘second-order filter set’ in the beam-path. More advanced instruments with an ability to read to higher absorbance levels (which would otherwise become impossible due to stray light) use two monochromators in series, such that (eg) 0.1% stray light from a single monochromator is reduced to 0.1% OF 0.1% by a second monochromator (0.000001%). This stray light performance is dramatically improved with the latest patented Lo-Ray-Ligh® grating technology from Shimadzu, in comparison to conventional designs, whilst retaining high throughput at the same time (Oppermann et al J Chem Chem Eng 7(2013) 1117-1120).

The detector technology has also evolved significantly. Early instruments had little option but to use Photomultiplier tubes, which still offer very high sensitivity, but are expensive and bulky and require very precise, high voltage power supplies and extensive electronic shielding of the signal. They are also typically effective over narrower wavelength ranges than the near-equivalent photodiodes. Newer devices are available such as already mentioned Silicon Photodiodes, which offer slightly less sensitivity but allow the much simpler design or CCD detectors that can use advanced signal processing to compensate for beam artifacts arising in the sample or monochromator optics. The overall design of modern spectrophotometers includes many components that counteract this loss of sensitivity. In the case of the UV-1900i, the Lo-Ray-Ligh® grating provides more input light, solid-state beamsplitter (instead of the rotating chopper) means that the instrument can be far more compact, and yet the overall performance is as far better in many cases, than older designs based on less well-designed gratings, rotating choppers, and photomultipliers. In addition, the UV-1900i uses two matched silicon photodiode detectors to give true double beam performance to achieve fantastic sensitivity at an extended wavelength range to 900 nm (A photomultiplier is typically limited to 900 nm).

The higher models of Shimadzu UV-Vis range, the UV-2600i, UV-2700i and UV-3600-i Plus, use photomultipliers in order to improve the sensitivity to the best possible. In addition, UV-2600i can operate at an extended rate of 1400 nm when used with the integrating sphere. It is, therefore, the only UV-Vis (normally 185-900 nm) instrument on the market that can also measure in the range between 1100 and 1400 nm. This extra range is useful for a lot of materials including photovoltaics, building glass, and laser optical components for communications lasers (fibreoptic).

The highest model, UV-3600-i Plus is equipped with three detectors providing optimal sensitivity across the entire 185-3300 nm range of the double gratings. These include a UV-Visible sensitive Photomultiplier, A very near-infrared InGaAs photodiode, and a Lead Sulphide detector for the range from approx. 1700-3300 nm.

All Shimadzu spectrophotometers in the latest UV-i range are true double beam systems. Double-beam designs have many advantages, but the main advantage is that the system is always completely compensating for any errors which could arise from slight fluctuations in the lamp energy or from warm-up effects on the instrument.

How has spectrometer software evolved?

From the earliest beginnings of computer control, software for instrument control has evolved even more than instrument hardware. The very first control packages were very elementary, usually communicating with a programmed mainboard inside the instrument and receiving part-processed data back which was displayed on the very low resolution (720 x 350) monochrome display. Printing was usually via a screen-dump to a dot matrix or daisywheel type printer. Eventually, color displays permitted an easier understanding of multiple traces on the same axes. The changes accelerated with the advent of Windows type PC operating systems, with massive increases in processor speeds, memory storage, and screen resolution. For a long while, there was a challenge regarding the communication between the instrument and the computer. The traditional COM port was used by some vendors, whilst others favored the IEEE format. In the end, USB seems to have become dominant. Modern software can control all parameters of the instrument. The most advanced software runs in a secure environment, allowing the process to be fully compliant with the FDA electronic records requirements (21CFR part 11) by storing all data and methods in database form. The very latest generation of software, such as the LabSolutions UV developed for the latest range of UV spectrophotometers, also allows fully automatic appraisal of all parameters from an investigation with automatic pass/fails to label for all samples, across any number of test parameters.

How does the new generation of Shimadzu spectrometers demonstrate a further evolution in the field?

Shimadzu’s latest generation of ‘I’ series spectrophotometers all shares the new and very powerful LabSolutions UV software. The software allows full evaluation of experiments across many parameters without operator ‘judgment’ being required and can operate in Database mode for full 21 CFR 11 compliance. At the heart of each Shimadzu Instrument, new patented technology ‘Lo-Ray-Ligh®’ diffraction gratings reduce the stray light and increase the beam energy throughput beyond any previous generation of grating, offering up to 10x higher stray light rejection. The result is instruments that have better signal to noise performance, faster data acquisition, lower stray-light, and higher productivity than ever before. The UV1900i has the fastest data acquisition rate of any scanning instrument (29000 Data points per minute). Some instruments claim higher survey scan speeds but only collect data at 4 or 5 nm steps, thus producing fewer data points per minute. UV-1900i can collect data at 1 nm steps, even at 29000 nm/min.

What other advantages does the new line of spectrometers have over anything else that is currently on the market?

Shimadzu has an impressive range of instrumentation to cover an array of applications. The Shimadzu range includes options for Deep UV (down to 165 nm) as well as offering the only compact instrument capable of reading to very high absorbance. The UV 2700i can read to in excess of 8.5A yet is one-third the size and less than a third of the weight of any competitive instrument able to read 8A or above. The Shimadzu UV 2600i can be fitted with a unique dual-detector integrating sphere extending the wavelength range to 1400 nm, again in a chassis much smaller than any instrument with a range above 1100 nm). The Shimadzu UV 3700i is able to measure very large samples with a fully automated x-y stage and is available in a deep UV version. The Shimadzu UV 3600i and UV 2600i/2700i models can be fitted with a large external sample compartment to allow measurement of absolute reflectance and transmission at variable angles and measure large assemblies such as lenses or large pieces of optical glass. All the Shimadzu range now have the LabSolutions UV software with fully automatic evaluation of color, haze, yellowness, film thickness, and other parameters normally only possible in specialist instruments.

What additional benefits does a user receive when choosing to use a Shimadzu spectrometer?

Shimadzu practices “Excellence in Science” and apply the concept throughout all aspects of the company to the advantage of our customers. With over 4000 members of staff working in the R&D department, instrumentation (both hardware and software) is continuously improving so users receive the latest cutting-edge technology with excellent performance. We are proud to have over 1 million satisfied UV-Vis spectroscopy customers globally since 1952. A consultative approach is applied in the sales process to ensure the customer has the most appropriate solution to their problem. Shimadzu also has a very comprehensive after-sales support system. The expertise of the Spectroscopy Technical Team can offer high caliber knowledge in the initial training through to ongoing support on a variety of applications. Finally, Shimadzu has a large, factory-trained service team that only works on Shimadzu equipment and know-how to optimize performance. The service team is also highly competent with all aspects of operation and compliance from validation to 21 CFR 11 compliance.

What’s next for Shimadzu?

What’s next? Shimadzu’s R&D is driven by scientific curiosity and designs tomorrow’s solutions - today. To provide Excellence in Science.

About Dr. Robert Keighley

Dr. Robert Keighley completed a degree in Applied Biological Sciences and then a Ph.D. in Biochemistry and Subcellular Fractionation. He began his Scientific Instruments career in 1985 with Liquid Scintillation Counter technology, then Laser Light Scattering Particle Counters, before joining Beckman Instruments where he specialized in Spectrophotometers, Liquid Scintillation Counters, Ultracentrifuges, and Analytical Ultracentrifuges. From there he moved to Varian Instruments to specialize in UV-Vis and FTIR, before joining Shimadzu in 2011. He has over 35 years of direct Scientific Instrument Experience after an Academic Introduction to the technologies during his degree and Ph.D. He has given lectures at many major scientific conferences across the globe on subjects from Identifying Microplastics in Deep Ocean sediments using Microscope FTIR to Revealing the Subunit Structure of Multimeric Peptides by Fluorescence and Analytical Ultracentrifugation.

Dr. Robert Keighley completed a degree in Applied Biological Sciences and then a Ph.D. in Biochemistry and Subcellular Fractionation. He began his Scientific Instruments career in 1985 with Liquid Scintillation Counter technology, then Laser Light Scattering Particle Counters, before joining Beckman Instruments where he specialized in Spectrophotometers, Liquid Scintillation Counters, Ultracentrifuges, and Analytical Ultracentrifuges. From there he moved to Varian Instruments to specialize in UV-Vis and FTIR, before joining Shimadzu in 2011. He has over 35 years of direct Scientific Instrument Experience after an Academic Introduction to the technologies during his degree and Ph.D. He has given lectures at many major scientific conferences across the globe on subjects from Identifying Microplastics in Deep Ocean sediments using Microscope FTIR to Revealing the Subunit Structure of Multimeric Peptides by Fluorescence and Analytical Ultracentrifugation.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.