Polyurethane manufacturing is a process conducted at high-temperatures under high-risk conditions. However, Near Infrared (NIR) analysis is a technique that offers a safe and cost-effective way to monitor polymer synthesis.

Employing remote insertion probes connected to a NIR analyzer with safer fiber optic cables limit the safety risks and protects the operator in contrast to the use of grab samples or sample conditioning systems. In addition, Process Insights’ proprietary SST and shuttle probes were designed to specifically resist high temperatures and pressures with reduced maintenance requirements.

As illustrated in the above diagram, process NIR analyzers for polyurethane synthesis provide solutions at various monitoring points throughout the industrial monomers and polymerization processes. From end-point reactions to water in diisocyanates, Process Insights’ NIR-O full spectrum analyzer can simultaneously monitor up to 12 sample locations, a single analyzer is as effective as multiple analyzers. Process engineers have improved control and considerable insight due to real-time analyses, without the delay of a grab sample, which in turn allows for effective and efficient processing.

What are Diisocyanates?

Diisocyanates are a strain of chemicals used to manufacture a wide range of polyurethane products. The most popular aromatic diisocyanates are methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI). Uncommon, but still valued diisocyanates are the aliphatic group, including hydrogenated MDI (H12MDI), hexamethylene diisocyanate (HDI), and isophorone diisocyanate (IPDI).

- TDI is typically used in the manufacturing process of flexible polyurethane foam present in a variety of everyday products, including bedding, furniture, packaging, and carpet underlay.

- MDI’s principal use is in the manufacture of rigid polyurethane foams such as insulation boards.

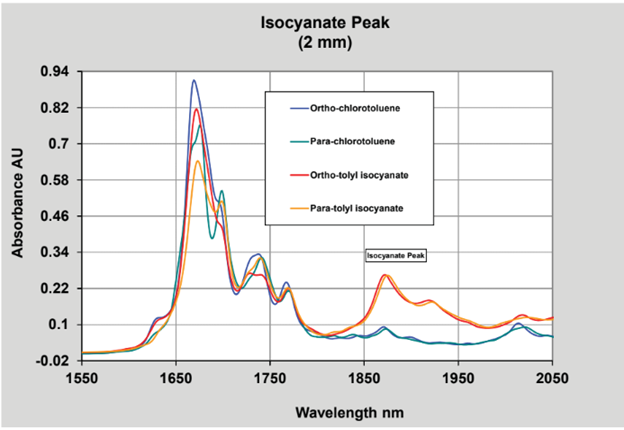

The 1875 nm Peak is Specific to Isocyanate and Allows for the Reaction to be Monitored with a ClearView db Photometer.

How Continuous NIR Process Monitoring Improves Yield During Diisocyanate Synthesis

Real-time monitoring with NIR analyzers provides extra-benefits to at several process points during diisocyanate production. For example, the return of TDI and MDI can be resolved. Additionally, the monitoring of the concentration of water is possible as this can often be the source of off-spec products that form in the reaction vessel. Once the reaction is fulfilled, the hydroxyl number (OH value) of the prepolymer can be observed to ensure the product is on-spec.

Improving Operational Safety Through Phosgene Leak Detection

Utilizing Process Insights’ High Safety Flow Cell, plant safety can be enhanced by monitoring the purity or concentration of phosgene. Built into a Class 300 flange, using welded fabrication, the High Safety Flow Cell makes use of double o-ring sealed sapphire windows and a weep or “tattletale” port to self-monitor for the failure of the o-ring. This safety mechanism enables the flow cell to be serviced once the process chemicals are established in the space between the seals of the first and second o-ring. Furthermore, by inserting a High Safety Flow Cell on the input side of the reactor vessel and the recovery line, variations in the amount of phosgene consumed by the process can be tracked, offering the prospect of an early-warning concerning a hazardous leak in the facility to plant-personnel.

NIR Analyzers can be Used for Reaction Endpoint Detection

Establishing reaction endpoint in the reactor is vital to accomplish the desired product properties, such as molecular weight. Knowing precisely when the reaction is finalized reduces batch conversion time, residence time, and lowers the general manufacturing cost. Significant improvements are achieved in the process control due to on-hand, real-time information without the delay of a grab sample.

How NIR Analyzers are Beneficial to Mono-Ethylene Glycol Synthesis

Polyurethane synthesis routinely begins by combining ethylene oxide and water in a thermal hydration reactor (about 200 °C). Utilizing near-infrared analyzers allows for the observation of reaction kinetics such as the concentration of excess water as well as the ratio of glycol reaction products. The process of ethylene oxide to ethylene glycol thermal conversion tends to return about 90–92% monoethylene glycol (MEG) and 8–10% heavier glycol products, mainly triethylene glycol (TEG) and diethylene glycol (DEG). Near-infrared measurements can be taken on the various glycols and also in the ethylene carbonate to ethylene glycol reactors.

Consequently, the water-glycol mixture from the thermal hydration reactor is then supplied to multiple evaporators where the water surplus is recovered and recycled. Finally, using vacuum distillation the water-free glycol mixture is divided into MEG and the higher glycols. Near-infrared analyzers can be utilized at this point to certify yield and other useful parameters.

Determining the Urethane Yield by NIR

Throughout polyurethane synthesis, the isocyanate is reacted with alcohol which results in a constituent urethane. This reaction procedure forms the carbamate functional group which creates the links in polyurethane. Together with hydroxyl number (OH value), NIR analyzers can be useful when monitoring the efficiency of conversion of isocyanate to urethane.

Monitor Up to 12 Reaction Points with a Single Analyzer

The Process Insights NIR-O Full Spectrum Analyzer is adept when it comes to the monitoring of up to 12 in situ locations lacking a stream switching or sample conditioning system. Combining the capacity of several analyzers into a single system and running fiber optic cables to each reaction point also offers immense savings on costs.

This information has been sourced, reviewed and adapted from materials provided by Process Insights – Optical Absorption Spectroscopy.

For more information on this source, please visit Process Insights – Optical Absorption Spectroscopy.