Recently, International Gas Detectors (IGD) finalized a large gas detection system project in collaboration with Medical Pipelines Services Ltd.

The Manchester Engineering Campus Development, for the University of Manchester, is the largest engineering campus in the UK, with more than three hundred (300+) IGD TOC-750 addressable gas detectors running 24/7 to protect students and staff.

The turnkey project was concluded with one of IGD’s Aftercare partners Medical Pipeline Services Ltd. The resultant installation contains over three hundred TOC 750 safe area detectors and ten TOCSIN 750 control panels connected to a centralized HMI panel, all protected by IGD’s 10-year guarantee.

This case study will explore the MECD facility, who Medical Pipeline Services Ltd is, and how IGD’s industry-first, 2-Wire Addressable gas detection systems are protecting students and staff at Manchester University.

Manchester University and MECD Overview

The largest engineering department in the UK, Manchester Engineering Campus Development, covering 80,000 sqm of research and educational space, is home to a community of 8,000 students, researchers and academics.

The MECD building configuration includes Engineering Building A and B, the James Chadwick Building (Upper Brook Street), Oddfellows Hall and York Street Building.

MECD makes up a world-leading research and innovation hub directly adjacent to two flagship centers of excellence – the National Graphene Institute and the Henry Royce Institute, the UK’s national institute for state-of-the-art materials research and innovation (both institutes have already installed IGD gas detection systems).

UoM MECD Teaching and Labs. Image Credit: International Gas Detectors Ltd

The University of Manchester places first in the ‘Impact Rankings,’ and this investment will make sure that Manchester remains out in the front of the field of conducting world-class research.

A variety of inert and toxic gases are used in various scenarios throughout the MECD building and across all other buildings. Gases such as nitrogen, oxygen, argon, carbon dioxide, carbon monoxide and fluorine can be found throughout the campus. UK legislation, therefore, requires a gas detection system on-site that can continuously monitor for these hazards.

In addition to legislative requirements, the system must be flexible to add or easily change gas types as the site evolves over time.

Gas Detection System Scope of Work – MECD

The initial plan at MECD was to provide connected gas detection systems across ten floors and three buildings as required.

Due to the required size of the gas detection system, the project was sent out to tender to a number of gas detection companies.

Unlike IGD, most of the tendering companies proposed dated analog technologies or PLC-based systems. These types of systems introduce a range of performance issues.

PLC (or Programmable Logic Controller) based systems are predicated on a long-standing approach in a process control environment. They can offer reasonable connectivity but also require custom programming. In gas detection terms, this is their downfall.

Gas detection systems are life safety systems and, therefore, necessitate strict third-party approval to accepted standards in the same way that fire and smoke detection systems do.

Custom programmed PLC systems fabricated using standard parts may not have undergone the necessary checks and cannot offer the level of security needed to meet safety standards.

This type of system typically uses analog detectors in field. Companies that offer approved systems but use analog detectors also present major downsides.

Shortcomings of Analog Gas Detectors

The analog systems used today are generally superseded by digital technologies. Analog detectors necessitate their own individual interface cable back to the controller. This makes them expensive when it comes to installation.

The detector head output signal requires calibration, as does the PLC or controller input. This may introduce errors when observing readings on controllers and detectors and significantly increase the cost of ownership.

Analog signals are also vulnerable to EMC interference from other nearby installations. This presents major issues, even in a small environment, such as a lab, not to mention the problems one may encounter in a large multi-gas detection system.

Functionality is also restricted, requiring a lot of meddling to add or change detector types, further exacerbating the ongoing cost of ownership. Such systems typically rely on traditional alarm signaling, which can be perplexing in a complicated engineering environment with numerous safety systems.

Analog (4-20mA) systems tend not to offer flexibility by design. This means they are difficult to adapt to change, particularly on sites/labs where gas hazards can often change, which means completely switching out gas detector heads to match the gas hazard.

IGD’s Gas Detection Solution

IGD’s solution for MECD and several other clients is its addressable gas detection systems. Developed in IGD’s specialized facilities, these systems are approved to international third-party approvals and are subjected to rigorous testing. This offers the client peace of mind, knowing that required safety standards have been met or exceeded.

The IGD systems on offer are completely digitally addressable, enabling efficient networking of detectors to controllers. IGD’s Sentinel+ technology platform facilitates the use of multiple detectors on a single 2-Core cable run up to 1000M. The detectors communicate and are powered over a 2-Core cable with no polarity requirement when installing.

This feature limits connection errors and significantly reduces installation time. Additionally, each detector is equipped with isolated I/O ports enabling interfacing to a range of other devices without the need for additional hardware and thereby reducing extra installation costs.

For MECD, this simplified the process of interfacing to gas control valves, ‘break glass’ units and illuminated signage, etc.

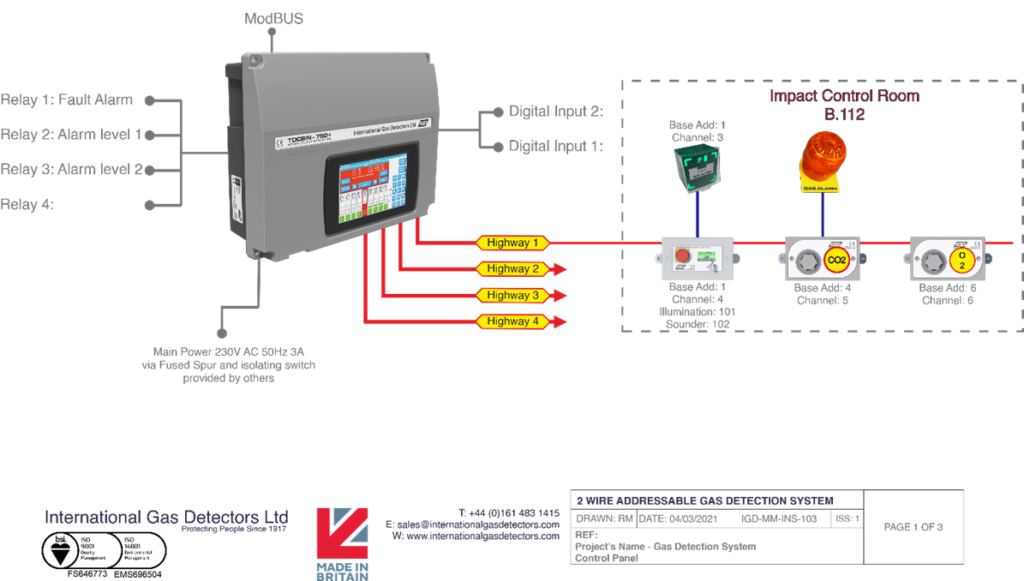

Control Panel

Typical Installation Line Diagram for MECD. Image Credit: International Gas Detectors Ltd

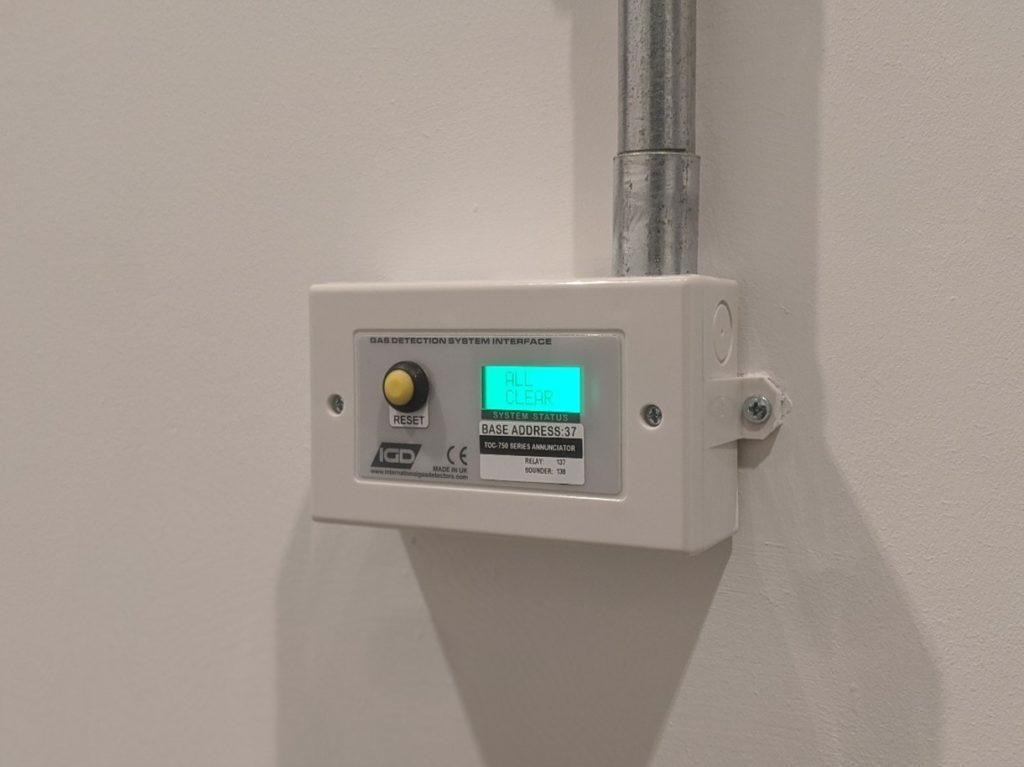

Additionally, room entries are safeguarded employing IGD’s Room Status Indicators. These offer a clear, straightforward indication in an otherwise complex environment. Room Status Indicators are installed and powered on the same cable run as the detectors.

TOC-750 Room Status Indicator installed at MECD. Image Credit: International Gas Detectors Ltd

Controllers can automatically ‘find’ and install connected devices, with each device feeding back precisely what it is and its status to the controller. As such, controllers automatically install detectors and room status indicators autonomously.

This eliminates potential commissioning errors when implementing new/modified systems and frees up the engineer’s time, allowing them to focus on the cause-and-effect alarm setup.

Controllers are also WiFi-enabled, securely facilitating offline programming and backup of each system. Clients have the ability to connect from any WiFi-enabled device to download event logs and system reports without the need for internet connectivity.

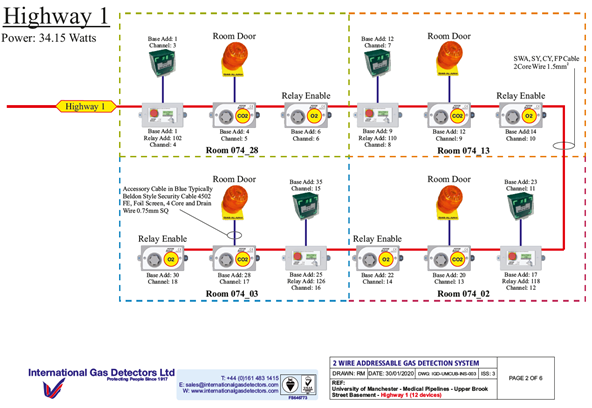

Typical Installation Line Diagram Created by IGD. Image Credit: International Gas Detectors Ltd

This allows both clients and service engineers to have access to full traceability: the system controllers (10 in total) all interfacing back to a centralized HMI panel. Controllers can have individual GSM connection for complete IoT (Internet of Things) connectivity.

The staff at MECD opted for a digital interface to a command HMI. This offers a complete overview of the entire system network with full data logging and trending facilities. Additionally, the HMI has connectivity to the site BMS system to facilitate effective alarm status.

IGD Remote Color Touch Screen HMI. Image Credit: International Gas Detectors Ltd

The TOC-750 addressable gas detectors were supplied with pre-calibrated further speeding installation, which enables rapid sensor swap out or replacement. This secondary detail is crucial as the systems can identify when a gas detector has been ‘hot swapped’ and then communicate and update the new sensor.

These hot-swappable sensors facilitate rapid replacement when detectors/sensors come to the end of their operational lifetime. An added benefit of IGD’s hot-swappable system is the capacity to also change gas types easily. This is well-suited for laboratories with varying requirements and gas hazards.

For example, switching from a CO sensor to a CO2 sensor on a traditional system would necessitate a specialized engineer and additional site work to modify the controller setup. On an IGD addressable gas detection system, however, it’s as simple as just changing the sensor, and the controller will pick up the change.

IGD TOC-750 Safe area addressable gas detector installed at MECD. Image Credit: International Gas Detectors Ltd

The TOC-750 series gas detector will automatically update to the new gas type, new range and update alarm levels. The detector remains in its configured alarm group so plugging in the new detector head is the only requirement. This offers complete flexibility in an ever-changing safety environment.

Of course, the other main advantage that digital technologies offer is that it is the same digital reading whether you’re observing it on a detector, at a room status indicator, on the controller, HMI, BMS or over the internet. The errors associated with analog systems are eliminated.

IGD’s Long Life Sensor Technology and 10 Year Warranty

Manchester University also gains benefits from IGD’s leading long-life sensor technology, ensuring their oxygen depletion, CO2, N2O and CO detectors come with a lifetime of over five years. The industry standard for oxygen and CO lifetimes are less than three years.

The university also benefits from IGD’s 10-year no quibble warranty on the electronics it manufactures, ensuring benefits from the most advanced gas detection technology with low maintenance cost.

IGD’s TOC-750S N2O detector is the only stable and commercially available N2O detector today.

TOC-750 Series Safe Area Gas Detector and Beacon Sounder installed in bottle store. Image Credit: International Gas Detectors Ltd

IGD Aftercare and Medical Pipeline Services

After effectively installing over 300 gas detectors at MECD, IGD has offered the university staff free training on integrating the gas detection system (s) into their site safe operating procedure (SOP).

IGD successfully trained Medical Pipeline Services on its certified gas detection service engineer’s course. This offers a number of benefits to both Medical Pipelines and the university.

Firstly, Medical Pipeline Services are now integrated into the brand new IGD Aftercare program. They can show the university that their engineers are completely trained and competent enough to maintain the IGD gas detection systems installed on-site.

Medical Pipeline Services attending IGD's gas detection installation and maintenance training. Image Credit: International Gas Detectors Ltd

Alex Tighe from Medical Pipeline Services comments on this project:

“The IGD 2-wire system with the TOC 750 panel was the perfect fit for the MECD project, offering the flexibility, potential for future expansion and the connectivity required to deliver a future proof installation.”

Tighe further explains his thoughts about working with IGD, IGD equipment and being part of the IGD Aftercare+ brand: “IGD have supported our project team all the way from product manufacturing through to technical support, becoming an IGD Aftercare partner has been an easy choice to make.”

This was a fantastic project to work on. It started just over 2 years ago with IGD assisting in the design of the system in conjunction with Medical Pipeline Services and the University.

Adam Pilkington, UK Sales Manager, IGD

Being part of IGD’s aftercare and training program, Medical Pipeline Services can ensure the gas detection systems at MECD are correctly maintained and keep up their 10-year warranty.

“This project not only demonstrates the capability of both IGD and Medical Pipeline Services, offering design, installation, service and training. But it also demonstrates the immense flexibility IGD’s ground-breaking 2-Wire Addressable gas detection systems have compared to what is currently available on the market. It also further demonstrates customer requirements for digital and IoT enabled gas detectors which is exactly what the TOC-750 systems provide. I am immensely proud of both Medical Pipeline Services and the IGD team for implementing and completing this project. It truly is both a monumental and historic project for the gas detection industry,” states Pilkington.

The Outcome

The MECD gas detection system is now one of many large UK gas detection projects IGD has completed using IGD’s 2-Wire Addressable gas detection systems. The MECD building now contains more than 300 digital addressable TOC-750 gas detectors with improved long-life sensors.

The university is equipped with an advanced, IoT-enabled, addressable gas detection system which is future-proofed owing to IGD’s excellent 10-year warranty and long-life sensors. IGD was pleased to work with Medical Pipeline Services, incorporating the company as part of the credited IGD Aftercare brand.

This project demonstrates the industry’s move towards true addressable technology and IoT-enabled gas detection systems, of which IGD are the main innovators and manufacturers.

For over a century, IGD has proudly manufactured gas detection equipment and has the ability to help users fulfill their gas detection requirements. From portable to fixed monitors and project design, and from installation to ongoing traceable service, no project is too big or too small for the IGD team.

Contact the IGD team today to benefit from the advantages of true addressable gas detection technology.

Image Credit: International Gas Detectors Ltd

Medical Pipelines Services Partnership

Medical Pipelines Services is a UK-based medical and industrial pipeline company. Founded in 1987, Stockport, Manchester, the company supplies a range of Medical, Laboratory and process gases services across numerous industries.

Since the company was founded, Medical Pipeline Services has diversified into the fields of Industrial gases, Specialist gases, Gas Detection and Maintenance. The company’s clients include some of the world’s largest pharmaceutical companies, NHS Trusts, Private Hospitals and Universities.

Medical Pipelines Services are now approved members of IGD’s aftercare program. This means the company and its staff can access IGD’s comprehensive training facilities. As part of the program, IGD provides Medical Pipelines with full certification to promote, supply and support the range of industry-first, addressable gas detection systems.

This partnership allows Medical Pipeline Services to offer their clients complete turnkey projects from pipeline installations with gas detection to continuous traceable calibration. Their engineers continuously access IGD training facilities, building upon and updating skills, allowing the Medical Pipeline Services team to further improve upon their service offering.

IGD is delighted to have Medical Pipeline Services as part of the IGD Aftercare program.

We are excited to officially have Medical Pipeline Services as part of our new IGD Aftercare brand and programme. We have been working with Medical Pipeline Services for a number of years, on multiple laboratory projects. It has been a fantastic success working with the team at Medical Pipeline Services and we look forward to have them as part of our authorized gas detection service engineer programme, IGD Aftercare.”

Colin Peake, Sales Director, IGD

Require a Gas Detection System?

IGD has more than a century’s worth of dedicated gas detection system design and manufacturing. With teams situated all over the UK and one of the largest global distributor networks, IGD can help you with total project support.

Discover more about the TOC-750 control panel by visiting the product page and learn about the TOC-750 safe area detector.

Contact the IGD team today to exploit the potential of addressable gas detection technology and have total support from system design to installation and ongoing aftercare.

This information has been sourced, reviewed and adapted from materials provided by International Gas Detectors Ltd.

For more information on this source, please visit International Gas Detectors Ltd.