Tsubakimoto Automotive, a primary manufacturer of industrial chain drives, large conveyor chains, and attachment chains, is dedicated to durability and functionality in its power transmission products.

Internal strength and durability criteria, alongside rigorous industry requirements, allow Tsubakimoto to achieve consistent and reliable test results. Such solutions improve the reliability of quality control processes while enhancing operational efficiency and maintaining high production rates.

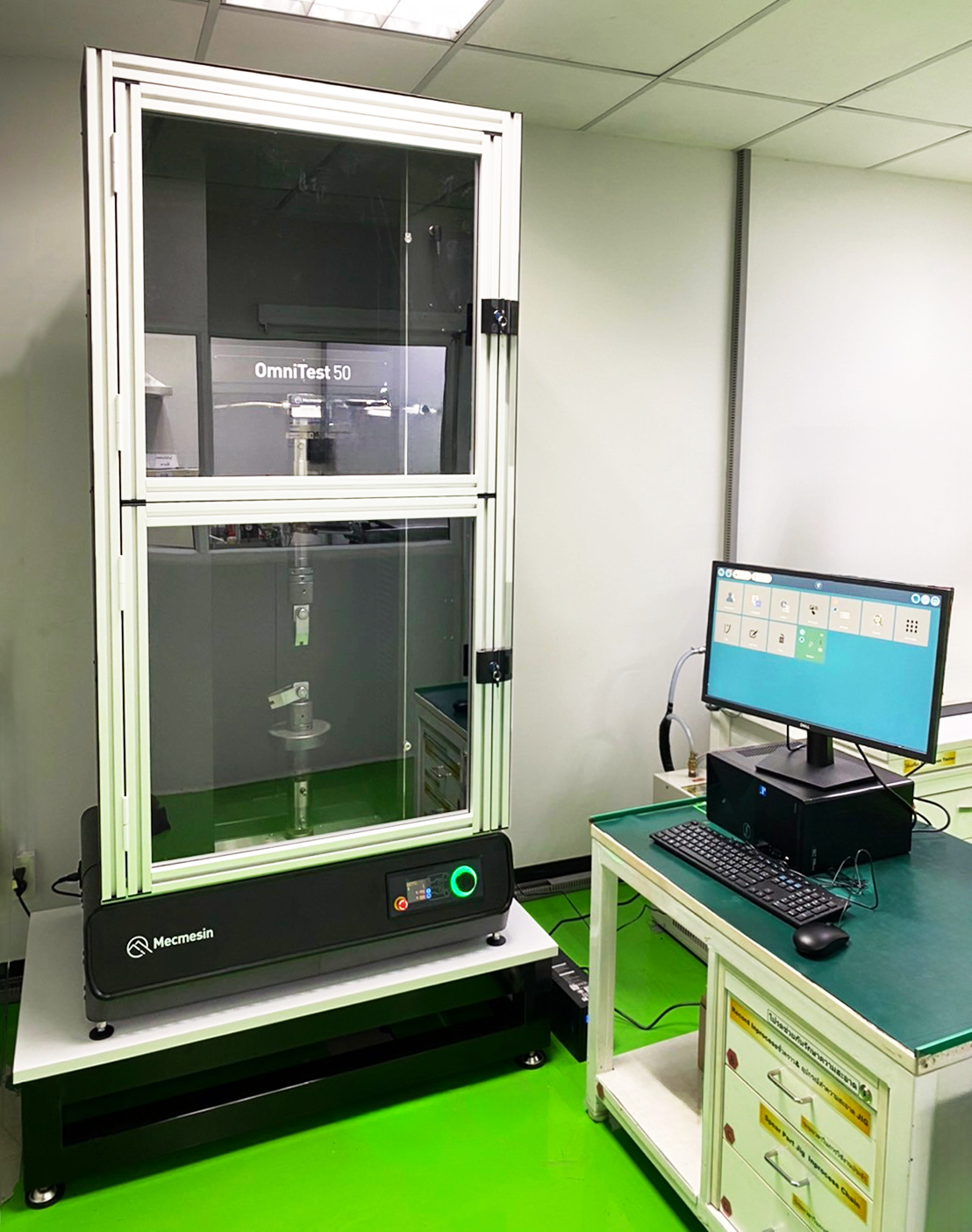

Image Credit: Mecmesin

Tensile Testing

Tsubakimoto required a system to perform multiple testing scenarios, including compression and tension testing, to guarantee that chain components meet demanding durability expectations.

Compression tests guarantee chains can endure compressive forces that could cause deformation. Tensile tests ensure chains can withhold the forces experienced during operation without elongation or breakage.

The particular internal standards and processes of Tsubakimoto necessitated a flexible testing system.

The Solution

Mecmesin delivered a complete, high-capacity universal testing machine (UTM) to meet these demands.

The OmniTest 50 kN twin-column UTM was coupled with Mecmesin’s VectorPro software, enabling precise tension and compression testing and allowing the business to evaluate strength and durability efficiently. The 50 kN ELS load cells deliver accurate force measurement and guarantee the tests align with internal standards and industry obligations.

One of the most important parts of this solution is the customizable test programs offered by VectorPro software. The software allows the company to integrate its unique test methods into the system and offers enhanced testing consistency and data accuracy. The intuitive interface simplifies managing testing protocols while reducing the chance of errors.

Image Credit: Mecmesin

Better Safety and Efficacy

The system is fortified with a high-quality interlocked safety guard to safeguard operators’ safety during testing. This characteristic averts potential accidents and injuries and creates a safe environment without reducing testing speed or efficacy.

By integrating the OmniTest 50 kN, the VectorPro software, and the safety guard, Tsubakimoto’s quality control processes have been significantly improved. The system delivers the testing accuracy and safety required to preserve high standards while streamlining production, meaning they can surpass internal and industry-wide potential for product performance.

This information has been sourced, reviewed, and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.