Welding pouch cells is key in manufacturing lithium-ion batteries. Preferred for their pliable and lightweight design, pouch cells comprise various layers of electrodes and separators enclosed in adaptable aluminum foil. Welding guarantees the cell’s hermetic sealing, pivotal for the battery’s safety and endurance.

The cell is initially housed in a specialized fixture that accurately aligns the foil layers before the aluminum foil’s open edges are secured using ultrasonic or heating welding.

In heat welding, the foil is warmed to a certain temperature, triggering the fusion of the materials. In ultrasonic welding, high-frequency sound waves disturb the foil’s molecules, making a solid bond.

Image Credit: Optris GmbH & Co. KG

Manipulating welding parameters like temperature, pressure, and time ensures a constant and dependable seal. Poor welding can cause leaks, potentially harming the battery or affecting performance.

Each cell endures leak testing following welding, usually through vacuum tests or helium leak detection. These quality assurance measures keep the cell free from air or moisture, which would impact its chemical stability and lifespan. Accurately welding pouch cells is vital to ensuring the quality and safety of new lithium-ion batteries.

The most integral part of sealing a pouch cell is surrounding the connectors (flags). Sealing the flags is tough because of their geometric shape. Manufacturing such battery cells requires a quality assurance test to verify that the cell welding is free of concerns.

High-Resolution Infrared Detection of Minute Battery Pouch Cell Leakage

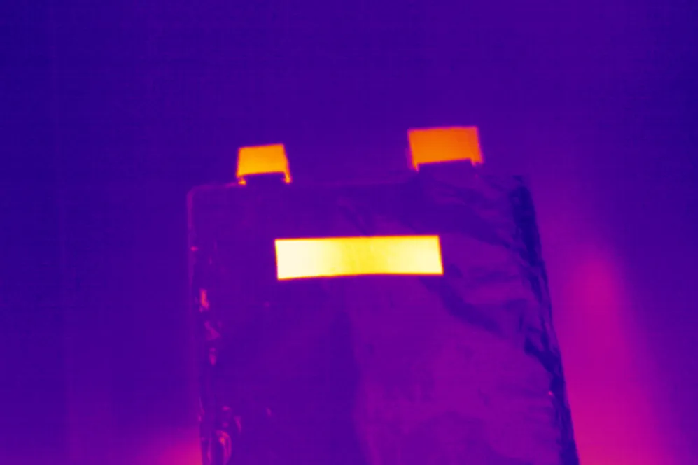

The flag’s edge traverses the foil, and if the sealing is weak here, it will prompt a temperature rise at the leakage site during load tests. A single-point pyrometer can only target the region if the precise position of a potential leak is identified.

An infrared image can highlight hotspots, simplifying the detection of leaks of unidentified position and size. These leaks can be minute, demanding the infrared image to capture minimal regions.

The temperature variation may be tiny if there is a slight leakage. The thermal image must, therefore, have high optical and good temperature resolution.

The aluminum surface presents issues for an 8–14 µm camera, but luckily, the flags are partly coated in the crucial region, improving emissivity and assisting exposure.

Image Credit: Optris GmbH & Co. KG

The Optris PI 640i infrared camera has a high optical resolution of 640 x 480 pixels, facilitating leak detection as little as 1 mm with the standard lens. This camera predominately identifies leakages to ensure battery pouch cell quality.

The software can mark the temperature difference as a standard for a good cell, initiating an alarm when an incorrect temperature deviation is identified. This alarm is dispatched to the control units, enabling each battery cell to be recorded with an “OK” or “NOK” mark from the infrared imager.

Battery pouch cells demonstrating a thermal difference revealing leaks are then scrapped. Quality assurance is now included in the automated manufacturing procedure.

Small MFOV, VGA Resolution, and low NETD are Crucial to Identify Defects

The video graphics array (VGA) resolution and low noise equivalent temperature difference (NETD) of 40 mK are critical for identifying battery pouch cell manufacturing leaks. The VGA resolution delivers a high optical clarity of 640 x 480 pixels, enabling comprehensive visualization of the cell surface.

This high resolution is crucial for detecting tiny faults that could cause major problems if unrecognized. The clarity afforded by VGA resolution ensures even the smallest abnormalities are noticeable, enabling accurate quality control.

Image Credit: Optris GmbH & Co. KG

The low NETD of 40 mK improves the infrared camera’s thermal stability, essential for identifying slight temperature differences that reveal possible leaks.

A low NETD indicates that the camera can discern very slight temperature variations, crucial for exposing tiny leaks where the variation might be minimal. This ability ensures no fault is overlooked, preserving cell integrity and safety.

The measurement field of view (MFOV) is crucial in battery pouch cell operations where uncovering small leaks demands high-resolution imaging. A low NETD, MFOV with a low NETD ensures the thermal camera can detect minor temperature variations, emphasizing possible concerns.

This spatial resolution is key for precise temperature measurement and quality control, making MFOV a crucial consideration in effective thermal imaging. The MFOV is fundamental for precisely defining the smallest target size required for accurate temperature readings.

In thermal imaging, MFOV is like the measuring spot in pyrometer devices, identified by a certain number of pixels. It ensures that 90 % of the target’s energy is captured.

This information has been sourced, reviewed and adapted from materials provided by Optris GmbH & Co. KG.

For more information on this source, please visit Optris GmbH & Co. KG.