Sponsored by Park SystemsReviewed by Olivia FrostJun 16 2025

Polymer materials have become increasingly important across various industrial applications due to their distinctive physical and chemical properties. Among these, Young's modulus is a key mechanical property, as it quantifies a material’s stiffness or rigidity.1

Temperature fluctuations can have a significant impact on the mechanical behavior of polymers.2 As temperature increases, Young’s modulus typically decreases, making the material more flexible and less rigid. This change occurs because thermal energy enables polymer chains to move more freely, reducing their resistance to stress-induced deformation.3-5

Understanding how a polymer’s mechanical properties respond to temperature variations is essential for designing materials that can perform reliably under diverse environmental conditions.

In this study, atomic force microscopy (AFM) was used to investigate how temperature affects the mechanical properties of polymer materials, with a particular focus on Young’s modulus. The PinPoint™ nanomechanical mode was employed to map localized areas of the polymer surface and estimate the average Young’s modulus—a mechanical property measurable by AFM.

To observe temperature-induced changes, a temperature-controlled stage (TCS) was integrated with the AFM system, allowing for continuous monitoring as the sample was heated from room temperature (RT, 25 °C) up to 170 °C.

AFM and TCS

These measurements were taken using the FX40, Park Systems' recently announced AFM model for research. The FX40 is a high-performance AFM model intended for research applications in a variety of domains, including nanotechnology, material science, life science, and semiconductor manufacturing.

It has various advanced features, such as high-resolution imaging and a diverse set of imaging modes. It also incorporates a high-precision motorized stage that allows for accurate sample positioning and scanning.

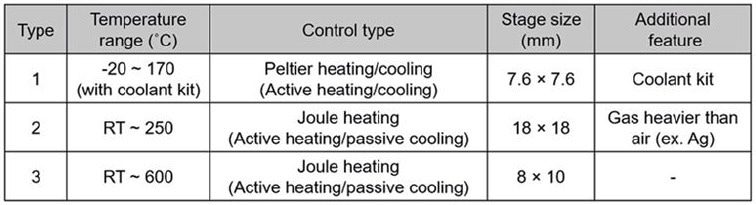

Park Systems also offers TCS, which can be coupled to an AFM model to measure changes in various sample parameters as a function of temperature. There are three types of stages, each with a particular temperature adjustment range, stage size, and hardware setup. TCS type 1 experiences rapid temperature changes because of active heating and cooling.

While TCS types 2 and 3 rapidly raise the temperature by active heating, passive cooling may take some time to lower the temperature (Figure 1). Depending on the type of TCS, it can be used at temperatures ranging from -20 °C to 600 °C.

In this study, type 1 was used, which has a temperature range of -20 °C to 170 °C.

Source: Park Systems

Figure 1. Three types of TCS modules of Park Systems. Image Credit: Park Systems

Result

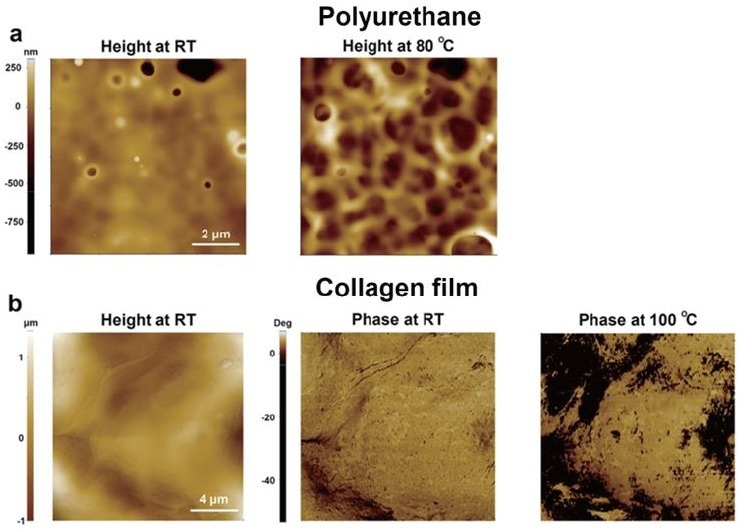

To begin, changes in the surfaces of polyurethane and collagen films resulting from temperature variation were examined using non-contact mode and Tapping mode, respectively.

As shown in Figure 2a, temperature changes noticeably affect the surface morphology of polyurethane.

At room temperature, the surface appears relatively smooth, but it becomes increasingly rough as the temperature rises. This roughening is likely due to a phase transition—from a crystalline to an amorphous state, or a shift between different crystalline structures.

Such transitions can alter the material's crystalline morphology, leading to reduced crystallinity or changes in crystal size and arrangement.6

Collagen, a temperature-sensitive material, also undergoes significant structural changes with increasing temperature. As illustrated in Figure 2b, elevated temperatures cause collagen film to denature, triggering changes in structure, surface morphology, and phase behavior.

This denaturation process compromises the structural integrity of the collagen, resulting in a rougher and more irregular surface.7

Figure 2. Topographical comparison of materials according to temperature change. Height images of polyurethane at RT and 80 °C (a), Height and phase images of collagen film at RT and 100 °C (b). Image Credit: Park Systems

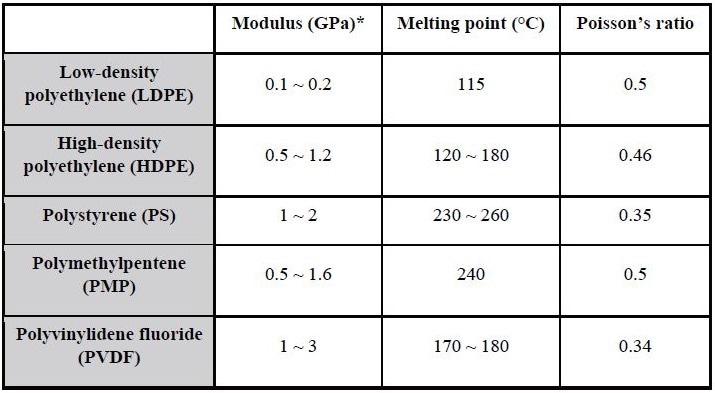

PinPoint™ nanomechanical mode was used to evaluate the Young's modulus of five polymers in response to temperature changes.

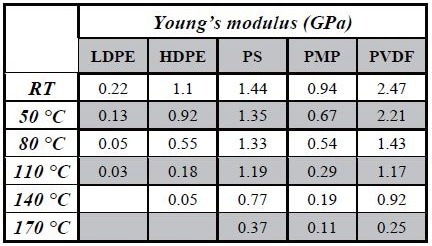

Low-density polyethylene (LDPE), high-density polyethylene (HDPE), polystyrene (PS), polymethylpentene (PMP), and polyvinylidene fluoride (PVDF) were chosen for this test because of their rigidity and melting point, as well as their thermoplastic properties (Table 1).

Polymers were made as 2×2×0.5 cm square films and bonded to a metal disk with a thermal compound.

Table 1. Properties of polymers. Source: Park Systems

All five polymers exhibit thermoplastic qualities, with a Young's modulus of 0.1 ~ 3 GPa and a melting point of 115 ~ 260 oC. Before the tests, the AFM probe was calibrated to ensure accurate and quantitative results.

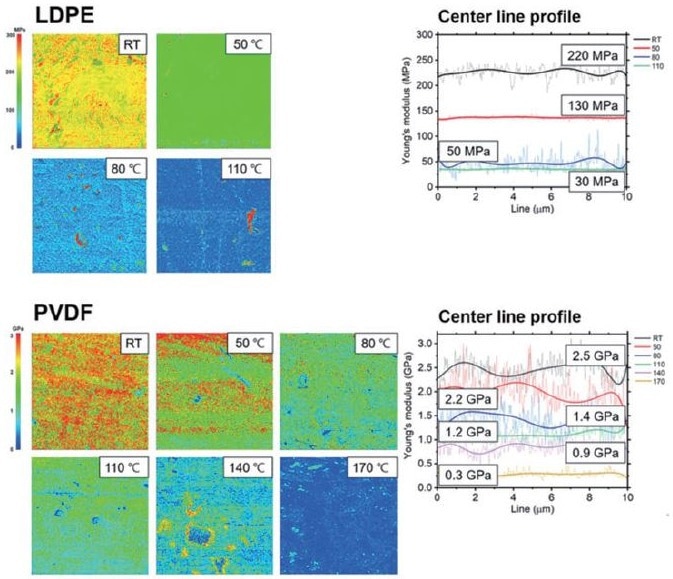

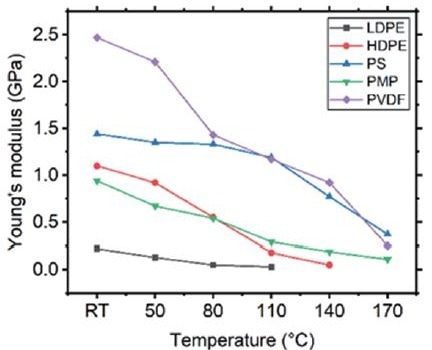

Figure 3 shows Young's modulus pictures of LDPE (which has the lowest Young's modulus and melting point among the five polymers) and PVDF (which has a high Young's modulus and melting point) as a function of temperature.

As shown in the Young's modulus images and the center line profile of each image, the polymers' Young's modulus drops as the temperature rises. This pattern is also verified by the data for all polymers in Table 2 and Figure 4.

Figure 3. Young’s modulus images and center line profiles at different temperatures. Young's modulus values at the center line profile indicate that the values decrease as the temperature increases. Image Credit: Park Systems

At increasing temperatures, the mobility of polymer chains increases due to increased thermal energy, making the polymer more flexible and less resistant to deformation.

This greater mobility lets the polymer chains move more freely and reorganize themselves when stressed, resulting in a lower Young's modulus. At higher temperatures, the intermolecular forces that hold polymer chains together weaken, contributing to a lower Young's modulus.

As a result, at higher temperatures, enhanced chain mobility and decreased intermolecular interactions combine to reduce a polymer's Young's modulus.

Table 2. Young’s modulus of polymers at different temperatures. All measurements were performed by PinPoint nanomechanical mode and analyzed by SmartAnalysis (Image analysis program, Park Systems). Source: Park Systems

All measurements were carried out using the PinPoint nanomechanical mode and analyzed using SmartAnalysis (Park Systems' image analysis tool).

Figure 4. The graph of Young’s modulus-Tempurature of 5 polymers. The graphical information shows a similar trend for all polymers. Image Credit: Park Systems

Conclusion

This article addresses the impact of temperature fluctuations on the mechanical characteristics of polymer materials, with a particular emphasis on Young's modulus. Using an AFM with a TCS, temperature-dependent variations in Young's modulus were investigated for a variety of polymers, including LDPE, HDPE, PS, PMP, and PVDF.

As the temperature of a polymer material rises, its Young's modulus normally drops, making it more flexible and less stiff.

Polymer characteristics vary based on their molecular structure, composition, and processing circumstances, including temperature.

Studying the temperature-dependent properties of polymers is essential across a range of industries, including materials science, polymer engineering, and polymer processing.

This knowledge supports the development of new polymer materials with tailored properties for specific applications, helps optimize processing conditions, and ensures the performance and reliability of polymer-based products under varying temperature environments.

By understanding how polymers behave and perform across different conditions, researchers and engineers can design materials with targeted characteristics to meet the demands of specific applications.

References

- Ward, I.M. and Sweeney, J. (2012). Mechanical Properties of Solid Polymers. Chichester, UK: John Wiley & Sons, Ltd. https://doi.org/10.1002/9781119967125.

- Shahabaz, S.M., et al. (2021). Influence of Temperature on Mechanical Properties and Machining of Fibre Reinforced Polymer Composites: A Review. Engineered Science, (online) Volume 16 (December 2021)(8), pp.26–46. Available at: https://www.espublisher.com/journals/articledetails/553 (Accessed 30 May 2025).

- Huang, P., Guo, Z. and Feng, J. (2019). General Model of Temperature-dependent Modulus and Yield Strength of Thermoplastic Polymers. Chinese Journal of Polymer Science, 38(4), pp.382–393. https://doi.org/10.1007/s10118-020-2360-7.

- Nasraoui, M., et al. (2012). Influence of strain rate, temperature and adiabatic heating on the mechanical behaviour of poly-methyl-methacrylate: Experimental and modelling analyses. Materials & Design, 37, pp.500–509. https://doi.org/10.1016/j.matdes.2011.11.032.

- Kendall, M.J. and Siviour, C.R. (2014). Experimentally simulating high-rate behaviour: rate and temperature effects in polycarbonate and PMMA. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 372(2015), p.20130202. https://doi.org/10.1098/rsta.2013.0202.

- Said Arévalo-Alquichire, Morales-Gonzalez, M., et al. (2020). Influence of Polyol/Crosslinker Blend Composition on Phase Separation and Thermo-Mechanical Properties of Polyurethane Thin Films. Polymers, (online) 12(3), pp.666–666. https://doi.org/10.3390/polym12030666.

- Shanmugam, G. and Polavarapu, P.L. (2008). Structural transition during thermal denaturation of collagen in the solution and film states. Chirality, 21(1), pp.152–159. https://doi.org/10.1002/chir.20598.

This information has been sourced, reviewed and adapted from materials provided by Park Systems.

For more information on this source, please visit Park Systems.