For scrap metal recyclers, having access to fast and reliable analytical technologies is critical. These tools enable accurate sorting of materials, ensuring consistent alloy composition and quality before recycled scrap is delivered to foundries and secondary aluminum producers.

Lightweight metals—such as magnesium, aluminum, and titanium alloys—are valued for their high strength-to-weight ratios and excellent corrosion resistance. These properties make them essential in sectors like automotive, aerospace, construction, packaging, and power infrastructure.1 As a result, many distinct grades of lightweight metal alloys are in circulation, each with unique compositions and characteristics.

Aluminum stands out as the most widely used lightweight metal, and demand continues to rise. This trend is driven by population growth and the increasing shift toward replacing steel components with lighter alternatives, especially in vehicle manufacturing, where reducing weight can improve fuel efficiency or electric range.

However, producing aluminum comes with a significant environmental cost. Roughly 3 % of the world’s direct industrial CO2 emissions come from aluminum production.2

A major portion of these emissions is linked to primary production, where aluminum oxide is refined from bauxite ore and then smelted into metal. This smelting process, typically done via the Hall-Héroult method, requires a substantial amount of electric power, often generated from fossil fuels like coal or natural gas.

Once produced, aluminum is considered a sustainable metal, as it can be recycled indefinitely without losing its physical properties. Products made from recycled aluminum scrap retain the same quality. Compared to primary production from ore, recycling aluminum reduces energy consumption by 95 percent.3

However, using scrap in aluminum alloy production presents challenges, since there exist a wide variety of alloy grades that are not interchangeable and mixed when collecting scrap. Accurate grade sorting in scrapyards is therefore essential. It helps streamline the recycling process by enabling the straightforward melting of scrap to recover alloys with the desired properties for specific applications.

A clear example is beverage cans, which can be recycled with a 100 percent recovery rate for the same use. But in many cases, recycling becomes more complex, especially when scrap comes from the same application but involves different alloy grades.

Milestones of Handheld Alloy ID Technologies

Handheld X-ray fluorescence analysis (HHXRF) was first introduced in scrapyards about 20 years ago, giving operators the ability to perform rapid, manual sorting of metal scrap across a wide range of alloys.

At the time, however, sorting aluminum alloys was limited. Available instruments could only differentiate between grades based on the presence of titanium and elements with higher atomic numbers, such as chromium, manganese, iron, nickel, copper, zinc, silver, tin, lead, or bismuth.

This was sufficient for sorting common wrought alloy grades from the 2000, 3000, 4000, or 7000 series—and to some extent, alloys in the 1000, 5000, and 6000 series—but precise identification based on magnesium and silicon content wasn’t possible.

That changed with the introduction of silicon drift detectors (SDDs) in HHXRF analyzers around 15 years ago, which made it possible to detect both silicon and magnesium. Still, accurately measuring magnesium at levels below 1 percent remained a challenge, and each reading typically took between 15 and 60 seconds—too slow for scrap operations that need to sort thousands of items daily.

A breakthrough in aluminum alloy sorting came about a decade ago with the introduction of handheld laser-induced breakdown spectroscopy (HHLIBS) analyzers.

This optical emission spectrometry method enables sorting of aluminum alloy grades based on magnesium content in as little as three seconds. However, it comes with some trade-offs.

For instance, HHLIBS is more sensitive to the condition and geometry of the specimen’s surface. Additionally, the transient nature of the light emitted from the plasma, generated by laser pulses, makes HHLIBS inherently less precise than HHXRF. In contrast, HHXRF benefits from continuuous X-ray emission, resultsing in more stable signal and better precisions.

Because of these limitations, the scrap metal industry has generally viewed HHLIBS as a complementary tool rather than a replacement for HHXRF analysis.

The versatility of HHXRF increased further with the development of LIBS technology, particularly through the introduction of instruments equipped with more powerful 5 W X-ray tubes and graphene windows on SDDs.

These advancements brought a five- to tenfold improvement in magnesium sensitivity. Still, the analysis process required two steps: measuring heavier elements in two to five seconds, followed by lighter elements in an additional three to ten seconds, bringing the total analysis time to five to 15 seconds.

While this marked a major improvement, it still couldn’t match the speed of HHLIBS instruments.

A New Approach to Sorting Lightweight Metals and Alloys

More recently, high-end HHXRF systems (see Figure 1) have reached a new milestone in the rapid identification of lightweight metals and alloys.

Unlike earlier methods, this new approach is specifically optimized for analyzing lightweight metals. It measures light elements, such as magnesium, aluminum, and silicon, alongside transition metals from titanium to zinc in the first phase, followed by heavier elements in the second phase. This configuration allows for the identification of the most common aluminum and magnesium alloy grades in just a few seconds, enabling scrapyard operators to sort these materials with very high throughput.

Figure 1. The Thermo Scientific™ Niton™ XL5 Plus Handheld XRF Analyzer offers a dedicated method for lightweight alloy analysis. Image Credit: Thermo Fisher Scientific

This approach is particularly effective for quickly sorting aluminum alloys that have similar concentrations of transition elements but differ in light element content. It helps prevent the mixing of casting alloys containing silicon with wrought alloys and is especially useful for separating “twin” alloys that vary only in their magnesium content.

One example is the distinction between 3003, used in rigid foils, containers, and signage, and containing no magnesium, and 3004, which includes about 1 percent magnesium and is commonly used for beverage cans. Another example comes from the aerospace industry, where alloy grades 2014 and 2024 differ solely in magnesium content, yet are not interchangeable.

This new analytical method for HHXRF instruments also proves highly effective when separating alloys that differ by only a few tenths of a percent in light element composition, such as silicon, magnesium, copper, or iron.

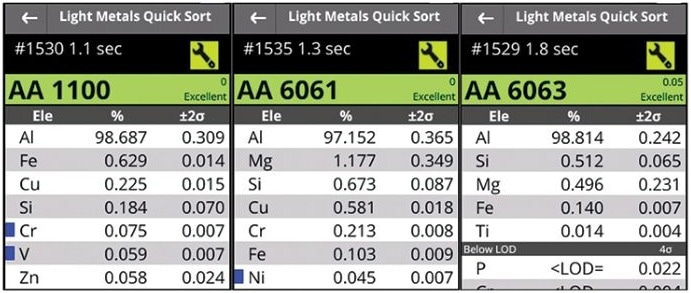

In the past, it was difficult to distinguish between application-specific alloys like high-value 6061—used in aerospace, marine, and automotive components—and more general-purpose grades like 6063 (used for window frames) or 1100 (used in cooking utensils, sheet metals, and similar applications).

Thanks to this updated method for analyzing lightweight metals, scrapyards can now sort these different grades in under two seconds, as shown in Figure 2.

Figure 2. Quantitative analysis and grade identification for aluminum alloys with similar composition can be achieved in less than two seconds. Image Credit: Thermo Fisher Scientific

Rapid and Reliable Analytical Technologies

Access to fast and reliable analytical technologies, such as HHXRF, is essential for scrap metal recyclers. These tools enable high-quality sorting, ensuring consistent alloy composition and grade when delivering recycled scrap to foundries and secondary aluminum producers.

In doing so, they help recyclers maintain the value of their aluminum scrap and protect their reputation by minimizing the risk of contaminants and unwanted materials entering the recycling stream.

The latest dedicated method for rapid analysis of lightweight metals further boosts productivity in aluminum and magnesium alloy sorting, thanks to significantly shorter measurement times—just a few seconds per sample.

References and Further Reading

- Canada. (2025). Natural Resources Canada | Ressources naturelles Canada. (online)Available at: https://natural-resources.canada.ca/minerals-mining/mining-data-statistics-analysis/minerals-metals-facts/aluminum-facts (Accessed 12 Jun. 2025).

- Simon, R. and Vass, T. (2023). Aluminium. (online) IEA. Available at: https://www.iea.org/energy-system/industry/aluminium.

- The Aluminum Association (2021). Infinitely Recyclable. (online) The Aluminum Association. Available at: https://www.aluminum.org/Recycling.

Acknowledgments

Produced from materials originally authored by Mathieu Bauer from Thermo Fisher Scientific.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Handheld Elemental & Radiation Detection.

For more information on this source, please visit Thermo Fisher Scientific – Handheld Elemental & Radiation Detection.