Mechanical materials testing is a fundamental method in quality assurance, utilized across material development, production, and laboratory settings.

However, the integration of artificial intelligence (AI) into this established field raises important questions: Can AI algorithms effectively evaluate tensile tests, detect anomalies, intelligently control test sequences, or even replace traditional testing methods?

The short answer is yes; in some instances, AI is already being implemented. But how does this technology operate, and what advantages and risks accompany its use?

Image Credit: ZwickRoell GmbH Co. KG

Capabilities of AI in Materials Testing

AI facilitates the rapid analysis of vast datasets generated during materials testing, allowing for the identification of patterns and deviations while enhancing process efficiency. This development is particularly significant in an increasingly digital and automated environment, often referred to as Industry 4.0.

This article discusses five critical areas in which AI is currently making a meaningful impact on mechanical materials testing.

1. Automated Evaluation of Tests

The process of analyzing a stress-strain diagram and interpreting key values like tensile strength can be time-consuming for laboratory personnel, especially when multiple samples are involved.

AI can expedite this process, often completing it in mere seconds. Algorithms identify relevant data points on curves or in results tables, regardless of whether the testing follows ISO 6892-1, ASTM E8 or other standards.

This efficiency not only conserves time but also minimizes subjective errors and highlights results that warrant further expert review.

In tests where optical analysis is crucial, such as hardness testing, AI enhances evaluation speed and accuracy, thus reducing the likelihood of errors.

Image Credit: ZwickRoell GmbH Co. KG

2. Anomaly Detection and Predictive Quality

AI can discern deviations and patterns in test data that may elude human observation, enabling predictive quality assurance by identifying batch deviations or faulty samples early in the process.

Centralized storage of all test data is essential for this capability, and the testXpert Analytics platform offers such centralized access to comprehensive test and machine data.

Image Credit: ZwickRoell GmbH Co. KG

3. Intelligent Test Planning and Adaptive Control

AI has the capacity to learn from previous tests and automatically recommend optimal test parameters, including force ranges, speeds, and temperature profiles. Coupled with adaptive systems, testing can adjust in real-time to the material's behavior.

It is crucial to note that adaptive control may not be permissible under all testing standards. However, where applicable, this capability can significantly expedite the testing process and reduce the occurrence of failed tests.

Image Credit: ZwickRoell GmbH Co. KG

4. Enhancing Robotics and Automation

In contemporary testing facilities equipped with robotic systems or sample handling technologies, AI facilitates intelligent control by employing image processing to recognize samples, automate sorting, and analyze their behavior during testing. This integration results in increased throughput and more stable processes.

For optimal performance, testing systems must support the integration of camera systems and other sensors. Achieving this necessitates modern measurement and control electronics, alongside testing software equipped with the necessary interfaces.

Image Credit: ZwickRoell GmbH Co. KG

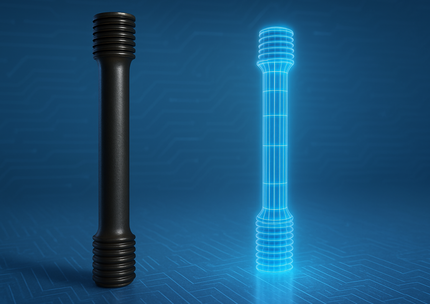

5. Digital Twins and Simulation-Based Testing

AI-supported digital twins can simulate real material properties and compare these simulations with actual test results. This capability allows for the virtual execution of certain aspects of mechanical testing, which is particularly advantageous for cost-intensive or hard-to-reach components.

In safety-critical fields, fully eliminating tests under real-world conditions is typically not allowed. A more practical approach combines simulation with carefully targeted real-world testing.

It is essential that the digital twin is continuously updated with real test results, which should be verified regularly to ensure its reliability.

Image Credit: ZwickRoell GmbH Co. KG

The Benefits of Utilizing AI

The potential benefits of using AI are substantial:

- Accelerated evaluations, resulting in shorter test cycles.

- Enhanced accuracy, as subjective evaluation errors are minimized.

- Cost savings achieved through reduced testing efforts and fewer rejections.

- Scalability, allowing for the analysis of large data sets without difficulty.

- Improved decision-making capabilities, facilitated by trend analyses or cluster recognition.

Risks and Challenges

However, not all that glitters is gold. The implementation of AI introduces new challenges:

- AI's effectiveness is contingent upon the quality of its training; incorrect or incomplete data can yield inaccurate results.

- Many AI models lack transparency regarding their decision-making processes, which poses a challenge in safety-critical testing scenarios.

- Current guidelines largely overlook AI, leading to inevitable legal uncertainties, and the integration of AI in calibration practices has yet to be uniformly defined.

- The replacement of human expertise with algorithms raises concerns about the potential loss of valuable know-how.

Conclusions

AI should not be viewed as a substitute for traditional testing methods; rather, it serves as a powerful complement.

When utilized effectively, it can enhance the speed, efficiency, and intelligence of material testing. Responsible management of AI is crucial: it should augment human expertise rather than replace it.

The future of materials testing is data-driven and ensuring that testing and machine data systems are prepared for AI integration is essential.

Centralized data storage, such as that provided by testXpert Analytics, along with flexible interfaces and integration options for image recognition systems, forms the foundation for this advancement.

This information has been sourced, reviewed, and adapted from materials provided by ZwickRoell GmbH Co. KG.

For more information on this source, please visit ZwickRoell GmbH Co. KG.