Observations at the nanoscale can provide profound insights into materials science. Yet, the characterization of beam-sensitive and reactive materials has proven challenging. In order to address this challenge, cryogenic focused ion beam scanning electron microscopy (Cryo FIB-SEM) technology has paved the way for the analysis of sensitive materials.

In this article, we will examine how Cryogenic FIB-SEM—for transmission electron microscopy (TEM) and atom probe tomography (APT)—overcomes these long-standing challenges and highlights its various applications in research.

Problem: Traditional Techniques Compromise Specimens

Following the advent of ultralow-dose scanning (S)TEM, researchers began capturing atomic-resolution images of highly sensitive nanomaterials. Since then, standard sample preparation techniques have typically utilized a traditional focused ion beam (FIB) system. This approach applies a concentrated stream of ions, usually gallium or plasma, to precisely mill small specimen regions, including thin lamellae for TEM and needle-shaped samples for APT.

FIB-SEM's ability to extract samples with site-specific and orientation-specific precision at the nanometer scale allows them to target critical features such as grain boundaries and interfaces with spatial resolution below 100 nm.

Despite its precision, FIB milling can inflict beam-induced damage, introducing structural defects like amorphous surface layers, curtaining, point defects, and unwanted reactions. Any of these faults can impact the integrity and thus analysis of a specimen.1,2

Challenges: The Difficulty in Preserving Native Structures

Under traditional FIB-SEM techniques, hydrated, low atomic number compounds and soft materials are susceptible to a range of defects. These can undermine the accuracy of sample preparation, particularly in sensitive applications, such as energy devices, polymers, and aerospace materials.

Material Degradation

Devices that rely on solid-liquid interfaces, such as dye-sensitized solar cells, fuel cells, and supercapacitors, are universally associated with energy generation, storage, and conversion. Preparing these samples typically involves removing liquids to prevent evaporation in high-vacuum instruments. However, the washing and drying processes required can cause structural and chemical changes to the soft or brittle materials present at the interface, potentially distorting their original characteristics.3

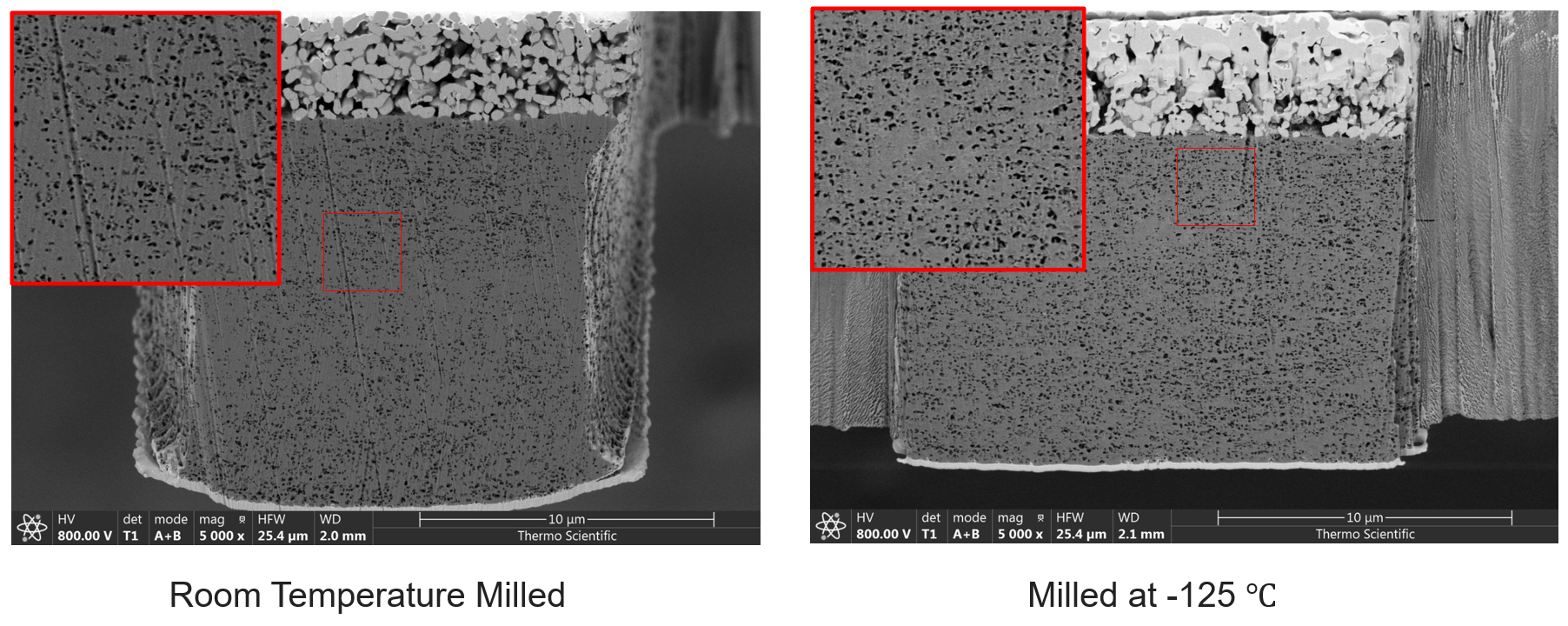

Room temperature vs. cryogenic FIB milling of Al2O3 ceramic coating on PE battery separator. Image Credit: Thermo Fisher Scientific

Unwanted Reactions

Highly reactive materials, such as alkali metals in lithium-ion and sodium-ion batteries, are also challenging to characterize, as they readily react with air or contaminants in the vacuum environment during sample transfer and milling. This reactivity can alter surface chemistry; for instance, lithium can form alloys with gallium during room-temperature milling, resulting in extraneous material rather than simply sputtering the target material.3

Hydrogen Embrittlement

Materials such as titanium, commonly used in aerospace applications, are particularly vulnerable to hydrogen embrittlement. The consequences of hydrogen uptake are a decrease in toughness and ductility. This effect takes place at room temperature and is exacerbated in FIB preparation, where beam-induced heating accelerates hydrogen diffusion and promotes undesired hydride formation.2

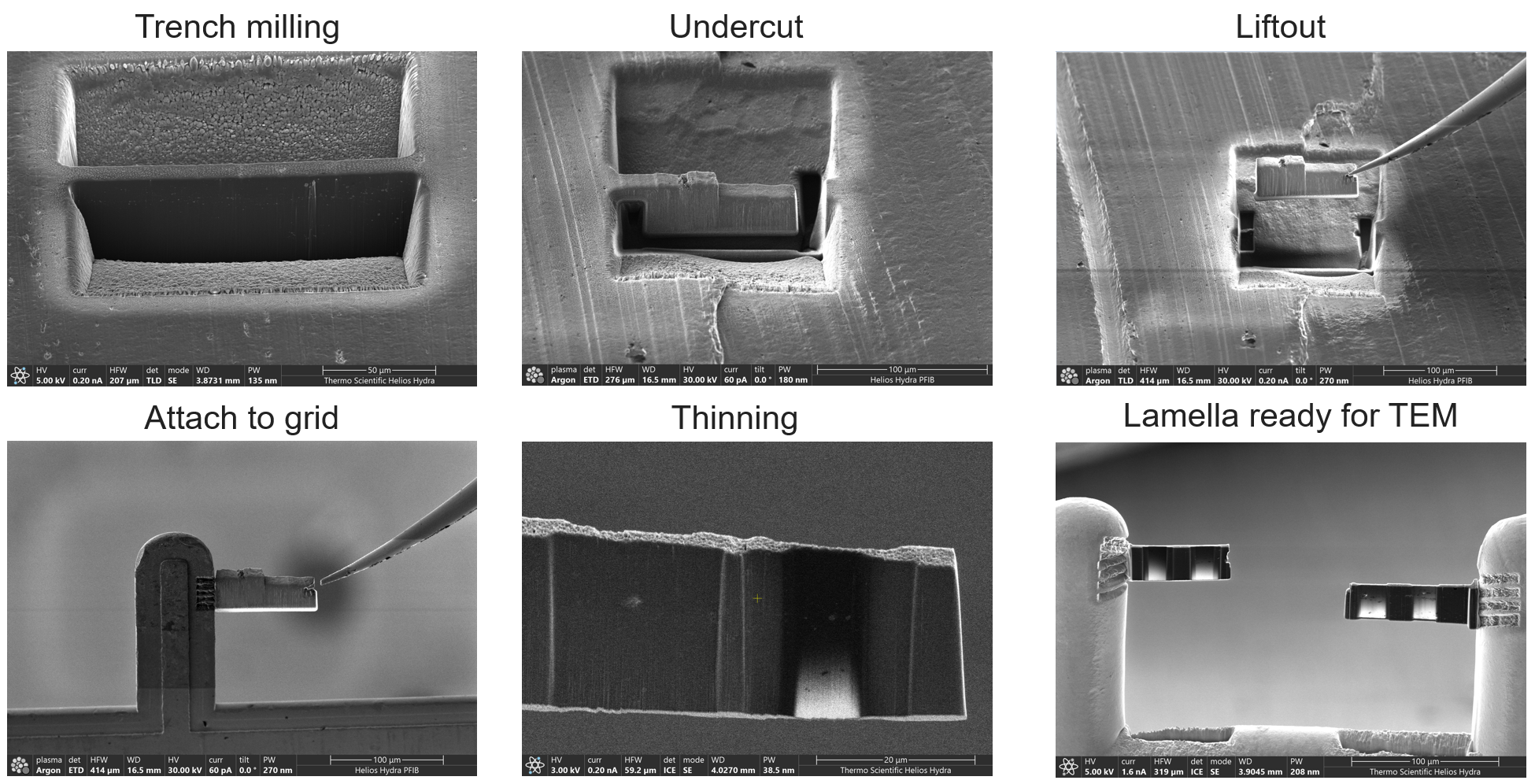

Li-metal TEM lamella prep process at -178 °C. Image Credit: Thermo Fisher Scientific

Solution: Enter Cryo FIB-SEM Technology

Cryo FIB-SEM technology is an advanced sample preparation and imaging technique used to analyze sensitive materials at temperatures below -100 °C. Combining FIB milling and SEM imaging/analysis with cryogenic cooling can stabilize samples, prevent unwanted reactions, and minimize structural damage during processing.4

How Cryo FIB-SEM Addresses Key Challenges

Preserving Solid-Liquid Interfaces: By rapidly freezing samples and transferring them into the instrument, Cryo FIB-SEM preserves solid-liquid interfaces, preventing unwanted reactions. This approach has proven effective in imaging solid-electrolyte interfaces in lithium-metal batteries, where it has revealed insights into failure mechanisms like dendrite growth.3,4

Mitigating Thermal Damage: The low-temperature environment of cryo FIB-SEM significantly decreases beam-induced thermal damage, enabling researchers to mill and analyze soft and beam-sensitive materials like lithium anodes and metal-organic frameworks (MOFs) without compromising their inherent structures. For example, researchers at KAUST have successfully used Thermo Scientific’s Helios 5 with CryoMat to prepare MOF specimens for high-resolution TEM and electron diffraction, preserving fine atomic structures that would otherwise degrade under standard FIB conditions.1

Preventing Hydride Formation in Titanium Alloys: Cryogenic Xe plasma FIB (Cryo-PFIB) minimizes hydrogen absorption, preventing the formation of brittle hydrides in TEM and APT sample preparations. This technique is especially valuable for studying environmentally sensitive materials like titanium used in aerospace applications.2

Thermo Scientific’s Cryo FIB-SEM Solutions

Thermo Scientific, a leader in FIB-SEM technology, has developed a suite of cryo-focused ion beam milling microscopes that address the challenges of traditional FIB methods head-on. Their cryo-FIB systems, such as the Helios and Scios DualBeam platforms, enable low-temperature (down to -190 °C) sample preparation with precise 360° stage rotation for full access to the sample. Equipped with Cryo EasyLift for complete TEM sample preparation, its cutting-edge features work in tandem to provide flexibility for various analyses, including high-resolution imaging and 3D volume imaging.5

Thermo Scientific’s integrated cryo FIB-SEM systems offer a streamlined solution for imaging beam-sensitive samples and preparing high-quality cryo-lamellae, setting a new standard for preserving sample integrity across industries. For more information on these systems, including the Helios and Scios models, please refer to Thermo Scientific's website.

Conclusion: Pushing Boundaries in Nanoscale Precision with Cryo FIB-SEM

By preserving sample integrity through all preparation and characterization stages, Cryo FIB-SEM mitigates issues like thermal damage, hydride formation, and unwanted reactions. Thermo Scientific’s cryo-focused ion beam milling microscopes, such as the Helios and Scios DualBeam platforms, are tailored to address these challenges, providing precise, low-temperature sample handling that supports high-resolution imaging and 3D volume imaging across a range of applications.

References and Further Reading

- Zhou, J., et al. (2022). Cryogenic Focused Ion Beam Enables Atomic-Resolution Imaging of Local Structures in Highly Sensitive Bulk Crystals and Devices. Journal of the American Chemical Society, 144(7), pp.3182–3191. https://doi.org/10.1021/jacs.1c12794.

- Chang, Y., et al. (2019). Ti and its alloys as examples of cryogenic focused ion beam milling of environmentally-sensitive materials. 10(1). https://doi.org/10.1038/s41467-019-08752-7.

- Zachman, M.J., et al. (2020). Nanoscale Elemental Mapping of Intact Solid–Liquid Interfaces and Reactive Materials in Energy Devices Enabled by Cryo-FIB/SEM. ACS Energy Letters, 5(4), pp.1224–1232. https://doi.org/10.1021/acsenergylett.0c00202.

- Jungjohann, K.L., et al. (2021). Cryogenic Laser Ablation Reveals Short-Circuit Mechanism in Lithium Metal Batteries. ACS energy letters, 6(6), pp.2138–2144. https://doi.org/10.1021/acsenergylett.1c00509.

- ThermoFisher Scientific. (2025). Cryo FIB | Cryo FIB Milling | Thermo Fisher Scientific - US. (online) Available at: https://www.thermofisher.com/ca/en/home/electron-microscopy/life-sciences/cryo-fib.html (Accessed 20 May 2025).

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Electron Microscopy Solutions North America.

For more information on this source, please visit Thermo Fisher Scientific – Electron Microscopy Solutions North America.