Microscopic analysis plays a fundamental role in materials science, enabling researchers to explore the fine details that influence product performance. Among the tools available to material scientists, environmental scanning electron microscopy (ESEM) stands out for its unique capability to study previously difficult materials in their natural, unaltered state. This article explores the potential of ESEM, the unique challenges it addresses, and how industries can leverage this technology to develop innovative products.

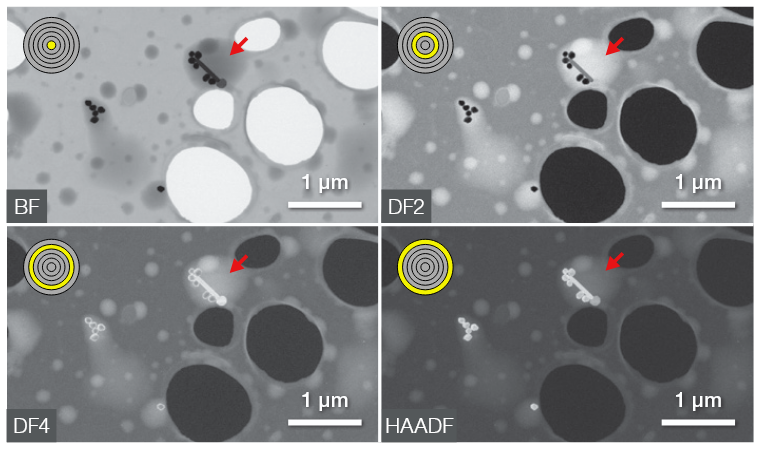

BF, DF2/4, and HAADF images of the silver nanoparticles in the water droplets. Image Credit: Thermo Fisher Scientific

The Challenge: Examining Complex Materials in Real-World Conditions

Traditional scanning electron microscopy (SEM) requires samples to be placed in a high-vacuum environment, which can alter or damage volatile, moist, or non-conductive materials.1,2,3 This limitation impacts the scope of SEM for studying many samples in their natural state, especially for industries and research fields that deal with complex, sensitive, and dynamic materials. Some of the most pressing challenges include:

- Moisture Sensitivity: Traditional SEM requires samples to be dehydrated, which is unsuitable for analyzing hydrogels and other hydrated specimens.4

- Non-Conductive Materials: To mitigate the charging effect in non-conductive samples, coatings are commonly used. While coatings are standard in high-vacuum modes, they are often unsuitable in certain applications like currency, museum samples, or those with very fine/delicate details. This is because the coatings can alter and/or obscure surface characteristics, which is key for proper analysis.5

- Beam-induced Degradation: Damage from the electron beam interactions is a common challenge in electron microscopy. While these interactions produce signals vital for material characterization, they can also alter the sample's surface or bulk structure, particularly in organic materials like polymers. Radiolysis often leads to structural changes, such as fragment recombination or surface deformation due to material loss from volatile fragment escape.6

- Dynamic Processes: Real-time investigation of certain processes such as wetting, drying, and water-based or gel type conditions are challenging using traditional SEM.2

These challenges demand a solution that allows for high-resolution imaging while preserving the integrity of samples and their real-world behavior.

The Solution: ESEM's Unique Capabilities

ESEM retains the imaging and analytical strengths of traditional SEM over other types of microscopy but introduces groundbreaking features that enable the study of challenging materials in real-world conditions. By using differential pumping and isolation valves, ESEM maintains a high-vacuum environment for the electron gun while allowing variable pressures in the sample chamber.1 This facilitates a number of advantages, including:

- Analysis in Natural States: ESEM enables the examination of wet, oily, volatile, and non-conductive samples without the need for drying or conductive coatings.1 Additionally, ESEM enables precise calculation of the critical electron dose for topographical degradation in sensitive polymers, providing a means to predict analysis limits without causing sample damage.6

- Versatile Environmental Conditions: With the ability to control temperature, humidity, and pressure, ESEM supports a wide range of applications, including studying corrosion and oxidation.1,7

- Dynamic Process Observation: Through capturing real-time changes, ESEM allows the investigation of hydration, setting, drying, and more.2

Applications Across Industries

ESEM has revolutionized how industries approach material analysis by enabling detailed studies of previously inaccessible samples. Below is a selection of real-world examples:

Composites Research

Aerospace companies have utilized ESEM to examine the transverse properties of carbon fibers, a critical factor in predicting the performance of composite materials. By imaging fiber cross-sections at various temperatures, ESEM measures changes in fiber diameter to calculate the transverse coefficient of thermal expansion. Techniques, such as epoxy embedding and graphite stabilization, ensure accuracy, while complementary TEM and EDS analyses reveal improved thermal stability in heat-treated fibers with enhanced graphitic ordering.8

Sustainability Research

ESEM has aided in asbestos recycling by enabling in situ monitoring of chrysotile's thermal decomposition into non-hazardous phases. By observing reaction kinetics and morphological changes, researchers have optimized processes, such as using low-melting glass to reduce decomposition temperatures, thereby cutting energy costs while ensuring complete asbestos transformation into safe, reusable materials.9

Image Credit: bieszczady_wildlife/Shutterstock.com

Frozen Aqueous Solution Research

ESEM has enabled the study of frozen aqueous solutions at subzero temperatures under near-natural conditions. Researchers have been able to observe intact ice samples, monitor changes in morphology, and analyze processes like ice sublimation with nanometer resolution. By simulating surface temperature and controlling water vapor partial pressure, ESEM ensures thermodynamic equilibrium, minimizing artifacts. Applications extend into the study of ice containing salts or proteins, advancing understanding in fields including atmospheric chemistry, biology, and the food and pharmaceutical industries.10

The Thermo Scientific Quattro ESEM: A Case Study in Innovation

Among the leading ESEM platforms, the Thermo Scientific Quattro ESEM stands out for its versatility and performance. Equipped with three vacuum modes (high vacuum, low vacuum, and ESEM), the Quattro accommodates a wide range of samples and experiments. Its unique capabilities include:

- Dynamic Imaging: With available cooling and heating stages, the Quattro supports experiments at extreme temperatures and environmental conditions.

- Live Elemental Imaging: The integrated ChemiSEM technology provides real-time compositional data, enabling researchers to make informed decisions on the spot.

- High-Resolution Analysis: The Quattro’s field emission gun (FEG) delivers exceptional imaging resolution, even for non-conductive or outgassing samples.

This combination of features has made the Quattro a preferred choice for industries looking to push the boundaries of material science.7

Conclusion: Advancing Material Science with ESEM

ESEM has revolutionized material science by overcoming the limitations of traditional SEM. Its ability to analyze samples in their natural state, observe dynamic processes, and operate under versatile environmental conditions has unlocked new opportunities for innovation.

From advancing composite research and sustainable recycling to studying hydrated materials and frozen samples, ESEM is a cornerstone technology across industries. Tools like the Thermo Scientific Quattro ESEM further amplify these capabilities, empowering researchers to explore the intricate details of materials and drive progress in fields that shape our modern world.

To find out more, get in touch with a member of the Thermo Scientific team today.

References and Further Reading

- Pipintakos, G., et al. (2021). Application of Atomic Force (AFM), Environmental Scanning Electron (ESEM) and Confocal Laser Scanning Microscopy (CLSM) in bitumen: A review of the ageing effect. Micron, 147, p.103083. https://doi.org/10.1016/j.micron.2021.103083.

- Manero, J.M., et al. (2003). Applications of environmental scanning electron microscopy (ESEM) in biomaterials field. Microscopy Research and Technique, 61(5), pp.469–480. https://doi.org/10.1002/jemt.10358.

- AzoMaterials. (2022). Analysis of Non-Conductive Samples in Table-Top SEM. (online) Available at: https://www.azom.com/article.aspx?ArticleID=21221.

- Francisco Drusso Martínez-García, Fischer, T., et al. (2022). A Beginner’s Guide to the Characterization of Hydrogel Microarchitecture for Cellular Applications. Gels, (online) 8(9), pp.535–535. https://doi.org/10.3390/gels8090535.

- Nanoscience. (2024). SEM Imaging of Uncoated, Nonconductive Samples. (online) Available at: https://www.nanoscience.com/blogs/sem-imaging-of-uncoated-nonconductive-samples/.

- Arnoult, C., Di Martino, J. and Ruch, D. (2012). Prediction and limitation of polymer degradation in Environmental SEM. Ultramicroscopy, (online) 122, pp.32–36. https://doi.org/10.1016/j.ultramic.2012.07.027.

- ThermoFisher Scientific. (2025). Environmental SEM | Quattro ESEM | | Thermo Fisher Scientific - US. (online) Available at: https://www.thermofisher.com/ca/en/home/electron-microscopy/products/scanning-electron-microscopes/quattro-esem.html (Accessed 20 May 2025).

- Ochoa, O. THERMOPHYSICAL ESEM & TEM CHARACTERIZATION of CARBON FIBERS CTE, SPECTROSCOPY and ROUGHNESS STUDIES at HIGH TEMPERATURES (Grant NAG 8 -1802) TEES Project Number: 64350 Project Report. (online) Available at: https://ntrs.nasa.gov/api/citations/20040015124/downloads/20040015124.pdf (Accessed 20 May 2025).

- Gualtieri, A.F., Magdalena Lassinantti Gualtieri and Tonelli, M. (2008). In situ ESEM study of the thermal decomposition of chrysotile asbestos in view of safe recycling of the transformation product. Journal of hazardous materials, 156(1-3), pp.260–266. https://doi.org/10.1016/j.jhazmat.2007.12.016.

- Kamila Závacká, et al. (2021). ESEM Methodology for the Study of Ice Samples at Environmentally Relevant Subzero Temperatures: ‘Subzero ESEM’. Microscopy and Microanalysis, 28(1), pp.196–209. https://doi.org/10.1017/s1431927621013854.

- Nedela, V., et al. (2024). Advanced environmental scanning electron microscopy reveals natural surface nano-morphology of condensed mitotic chromosomes in their native state. Scientific Reports, (online) 14(1). https://doi.org/10.1038/s41598-024-63515-9.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Electron Microscopy Solutions North America.

For more information on this source, please visit Thermo Fisher Scientific – Electron Microscopy Solutions North America.