In this interview, AZoMaterials speaks with Dr. Max Junda, Senior Member of the Technical Staff at Covalent Metrology and Dr. Lyle Gordon, Director of Materials, Chemistry and Surfaces Group at Covalent Metrology, about advances in thin film metrology. They explore the latest measurement technologies, challenges with modern materials, and strategies for characterizing complex structures.

Can you please introduce yourself and your role at Covalent Metrology?

Dr. Lyle Gordon: I’m Lyle Gordon, Director of Materials, Chemistry and Surfaces Group at Covalent Metrology. My background is in materials science, and I’ve spent much of my career working with high-resolution microscopy and spectroscopy. At Covalent, I lead efforts in surface science and thin film characterization and support clients across various industries in solving complex measurement challenges.

What are the most common requests Covalent receives for thin film metrology?

Dr. Lyle Gordon: We frequently get requests to measure film thickness, refractive index, extinction coefficient, and roughness. These are especially important for optical coatings, semiconductor materials, and transparent films. Many clients also seek evaluations of layer uniformity and assistance in characterizing complex multi-layer stacks.

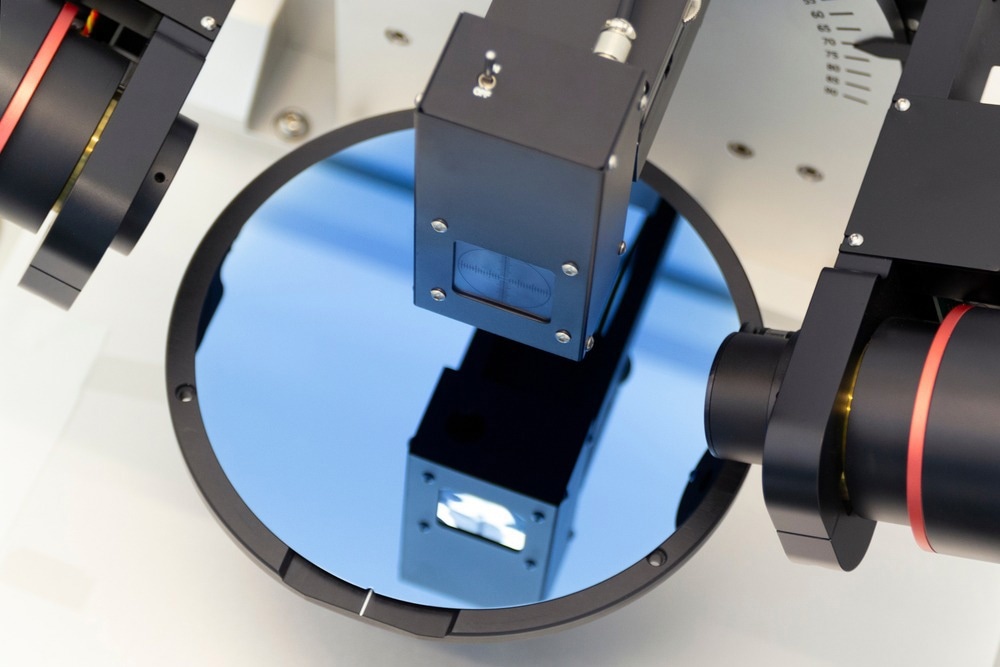

Image Credit: Titolino/Shutterstock.com

What are the main challenges encountered when measuring thin films?

Dr. Lyle Gordon: One major challenge is the increasing complexity of material stacks. We now see more layers, thinner films, and unique material combinations. Modeling these accurately can be difficult, particularly when materials are unknown or proprietary. Surface roughness and limited optical contrast can also complicate non-destructive measurements.

How do optical techniques like ellipsometry contribute to thin film characterization?

Dr. Lyle Gordon: Ellipsometry is incredibly powerful for non-destructive analysis of transparent films. It measures how polarized light changes when reflected off a sample, which lets us infer thickness and optical constants. It is especially useful across a wide thickness range, from sub-nanometer layers to several microns, and excels with smooth, well-defined film structures.

What role does X-Ray reflectivity (XRR) play in metrology?

Dr. Lyle Gordon: XRR is especially helpful for thin, smooth films that might be opaque to visible light. It works by measuring interference patterns in reflected X-rays to determine film thickness, density, and roughness. It is a great complement to ellipsometry when optical transparency is limited.

When optical or X-Ray techniques are not sufficient, what alternative methods are available?

Dr. Lyle Gordon: If the film is too rough, complex, or has unknown properties, we often turn to cross-sectional imaging such as SEM or TEM. These are destructive methods, but they provide direct visuzalization and are excellent for reverse engineering. We also use XPS for ultra-thin surface layers, which lets us determine thickness by analyzing signal attenuation.

What techniques are best for extremely thin films, such as those under 10 nm?

Dr. Max Junda: For ultra-thin films, we often rely on ellipsometry or XRR, depending on the material. Ellipsometry is sensitive to even small changes in polarization and can detect thickness variations in the angstrom range, assuming good optical contrast. XRR works well for uniform very smooth films down to single nanometer thickness.

Can you provide an example of how these methods are used in a real application?

Dr. Lyle Gordon: In one project, we helped a client measure an anti-reflection coating on a glass optical element. Initially, we didn’t know the number of layers or materials used. We prepared a TEM cross-section to reveal the stack and identify the materials with elemental mapping. This allowed us to build an accurate ellipsometry model and validate performance.

About Dr. Max Junda

Dr. Max Junda is a Senior Member of the Technical Staff at Covalent Metrology, where he focuses on ellipsometry and optical modeling. He received his Ph.D. in Condensed Matter and Materials Physics from the University of Toledo and his Bachelor in Physics from the Middlebury College.

With a strong background in thin film characterization and optical modeling, Dr. Junda plays a key role in method development and client consultation at Covalent. His expertise spans transparent and absorbing materials, multi-layer film stacks, and precision metrology for complex optical coatings.

About Dr. Lyle Gordon

Dr. Lyle Gordon is the Director of Materials, Chemistry and Surfaces Group at Covalent Metrology. He earned his Ph.D. in Materials Science at Northwestern University and holds a Bachelor of Applied Science from the University of Toronto. He has extensive expertise in time-of-flight mass spectrometry, particularly related to his work on atom probe tomography.

Dr. Gordon brings a deep understanding of surface and interface analysis, supporting research and development across industries such as semiconductors, coatings, and nanomaterials. At Covalent, he leads a multidisciplinary team focused on advancing analytical capabilities in materials science.

This information has been sourced, reviewed and adapted from materials provided by Covalent Metrology.

For more information on this source, please visit Covalent Metrology.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.