Researchers in India have engineered a 200 L hybrid photobioreactor that captures industrial CO2 emissions and converts them into biodegradable plastic using indigenous microalgae.

Image Credit: Uellue/Shutterstock.com

Image Credit: Uellue/Shutterstock.com

The system combines microbubble technology, automated CO2 regulation, and 3D-printed components to enhance bio-fixation and produce polyhydroxybutyrate (PHB), a sustainable polymer.

The study, published in Frontiers in Chemical Engineering, presents a scalable and energy-efficient route for linking carbon capture to high-value material production, without relying on fossil-derived feedstocks.

Get all the details: Grab your PDF here!

Conventional CO2 capture systems, including amine scrubbing and direct air capture, are energy-intensive and costly. Microalgae can provide a low-input alternative, but many systems suffer from poor gas-liquid transfer and limited scalability.

To address this, scientists at the Indian Institute of Technology Delhi developed a hybrid photobioreactor designed to run on 5 % CO2 - typical of industrial flue gas.

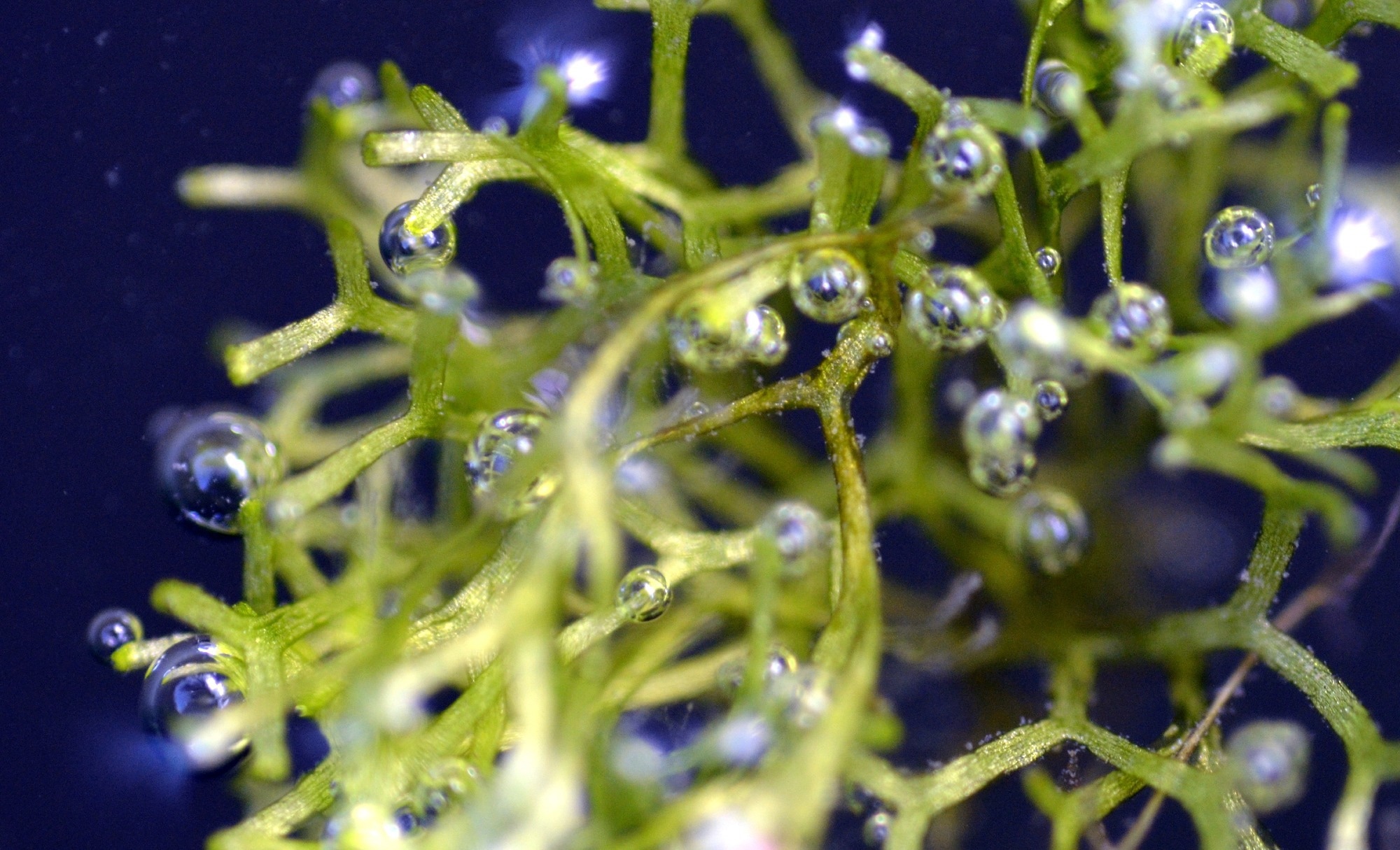

At its core is Poterioochromonas malhamensis, a microalga sourced from a sewage treatment plant, which has been shown to thrive under nutrient-limited and high-CO2 conditions.

3D Printing with Hydrodynamic Precision

The reactor integrates a stereolithography 3D-printed Venturi-based microbubble generator. Six parallel channels inject microbubbles, ranging from 400 to 800 µm in diameter, into a 1.2-metre carbonation column.

High-speed imaging and MATLAB-based analysis confirmed microbubble densities above 60 % even at the column top, indicating minimal coalescence and sustained gas-liquid contact.

The system's performance was benchmarked against a control raceway pond without microbubble assistance, confirming significantly improved CO2 dissolution and fixation in the hybrid design.

Automation Leads to Stability

An automated pH-feedback loop regulates CO2 dosing in real-time, maintaining the culture medium within the optimal pH range of 7.2-8.5.

This automation reduces the risk of carbonate oversaturation, a common issue in traditional sparging systems, and ensures stable conditions for algal growth.

The reactor produced a biomass concentration of 0.423 g/L, with carbon accounting for over 43 % of the dry cell weight. The CO2 bio-fixation rate reached 44 mg/L/day, with PHB yield at 5.8 % of dry biomass.

While lower than yields seen in heterotrophic processes, the result is notable for being achieved using only inorganic carbon under photoautotrophic conditions.

Polymers Created from CO2

Polyhydroxybutyrate accumulation was verified using spectroscopic and chromatographic techniques, including FTIR and gas chromatography. The ability to synthesize a biodegradable polymer directly from atmospheric CO2 makes this system a potentially revolutionary answer to industrial circular carbon.

The use of an indigenous algal strain also enhances the reactor's sustainability profile, improving adaptability to local environmental and resource conditions.

A Scalable, Sustainable Model

This pilot-scale study advances previous lab-scale work by demonstrating the feasibility of upscaling without compromising yield or stability.

The integration of precise hydrodynamic engineering, 3D manufacturing, and automation provides a blueprint for next-generation carbon capture and utilization systems.

The authors argue that microbubble-assisted photobioreactors can serve as practical, dual-purpose platforms - supporting both emissions mitigation and renewable materials production.

Journal Reference

Dey, S., Sahu, A. et al. (2025). Engineering an automated microbubble-assisted hybrid photobioreactor for CO2 capture and valorisation to polyhydroxybutyrate in indigenous algal biomass. Frontiers in Chemical Engineering, 7, 1701857. DOI: 10.3389/fceng.2025.1701857.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.