Sponsored by RETSCH GmbHReviewed by Emily MageeAug 26 2025

Over the past few decades, intensive research and development efforts have led to the creation of more than 10,000 distinct polymers—versatile materials that are now essential across a wide range of industries.

From packaging and automotive components to electronic devices, medical products, and construction materials, polymer-based items are deeply embedded in our everyday lives. However, this diversity also brings significant challenges to material processing, especially when it comes to sample preparation for analysis, the development of new materials, and efficient recycling.

Cutting Mill SM 300. Image Credit: RETSCH GmbH

Efficient Plastic Grinding: From Coarse Pre-Grinding to Ultra-Fine Powders

The SM 300 cutting mill delivers outstanding performance in the lab, reliably and efficiently grinding injection-molded parts, thick-walled packaging, and robust samples like PET preforms.

With the ability to handle bulky materials up to 80 mm in feed size and a generous 30-liter collection volume, it’s well-suited for preparing larger sample quantities for further analysis or research.

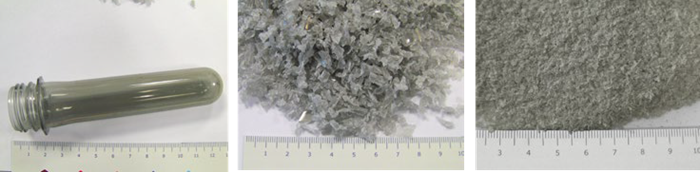

As illustrated in Figure 1, this powerful cutting mill can crush even large polymer components, thanks to its innovative flywheel mass design.

Figure 1. Pre-crushing and fine grinding of PET preforms using full speed of 3,000 rpm to overcome blockages and using a cyclone unit to effectively transport the material into

the receptacle. For crushing, a 6-disc rotor was used. For Pre-crushing a 6 mm bottom sieve was applied and in the second step for fine grinding a 1 mm bottom sieve . For a

sample of 5 preforms, each crushing step takes 20 seconds. Image Credit: RETSCH GmbH

A finer sieve insert can be employed in the SM 300 for finer grinding tasks. Alternatively, the ZM 300 ultra-centrifugal mill is recommended for achieving especially fine powders. Utilizing a high-speed grinding principle, the ZM 300 achieves narrow particle size distributions and offers flexible fineness down to 300 µm, as shown in Figure 2.

Ultra Centrifugal Mill ZM 300. Image Credit: RETSCH GmbH

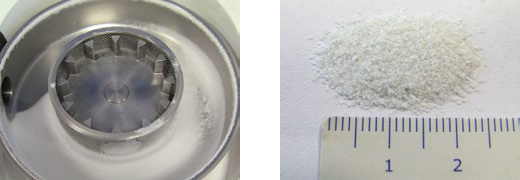

Figure 2. Fine grinding of polymers with the ZM 300 using a cyclone. The ZM 300 is a high-speed rotor mill with a rotational speed of up to 23,000 rpm. In this example, a few grams of pre-cooled LDPE sample material is ground at 20,000 rpm using a 12-tooth rotor and a 1 mm distance sieve, applying shear and cutting forces for size reduction. Image Credit: RETSCH GmbH

However, not all plastics are amenable to grinding. Some may be too soft for fine crushing or temperature-sensitive, potentially melting due to the heat generated during the milling process. In such instances, cooling becomes crucial.

Utilizing a cyclone, gradual stepwise milling of smaller sample amounts, or active cooling methods, such as mixing samples with dry ice or freezing them in liquid nitrogen, can yield significant results.

The CryoMill is specifically designed for these situations. It excels at fine grinding soft or temperature-sensitive samples, such as rubber, elastomers, or bio-based plastics, to a high degree of fineness. Continuous cooling of the sample with liquid nitrogen makes the material brittle enough to be efficiently ground into a fine powder using the impact and friction forces characteristic of a ball mill.

Mixer Mill CryoMill. Image Credit: RETSCH GmbH

Figure 3. Fine grinding of LDPE is performed in a CryoMill, which automatically uses liquid nitrogen to freeze the sample. After 9 cycles - each consisting of 1 minute of grinding at 30 Hz followed by a 1-minute cooling break - 6 g of LDPE is ground to a final particle size of 500 μm. Image Credit: RETSCH GmbH

Mechanochemistry: Sustainable Approaches to Plastic Recycling

Mechanochemistry harnesses the energy and fragmentation produced during grinding to induce specific chemical changes in polymers, thereby generating new material properties.

This promising process allows for the depolymerization of PET bottle waste in ball mills through mechanochemical activation, enabling the recovery of high-quality monomers for new PET products without the use of environmentally harmful solvents.

This sustainable method facilitates efficient plastic recycling and the potential production of entirely new materials.

Sieving: Ensuring Precision in Particle Size Analysis

Sieving is a fundamental technique for particle size analysis and the classification of materials into specific particle size fractions.

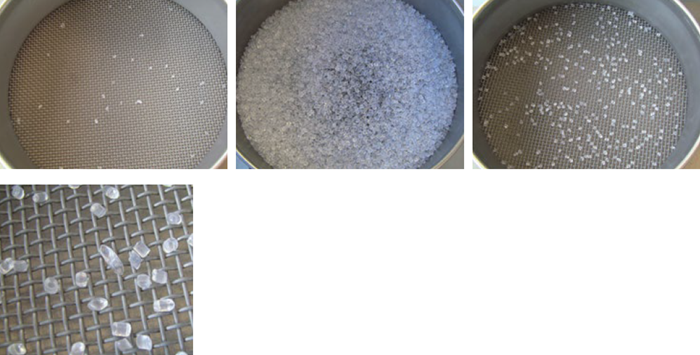

Sieving machines such as the AS 450 series with a sieve diameter of up to 450 mm and the AS 200 series with a diameter of up to 203 mm effectively separate powders by grain size, ensuring narrow particle size distributions, as demonstrated in Figure 4.

In applications such as additive manufacturing and recycling, these machines are utilized to categorize materials into distinct fractions based on particle size or material type, facilitating the production of homogeneous granulates for further processing.

For instance, achieving optimal layer thickness and printing precision in 3D printing necessitates precise particle size control.

Retsch sieving machines can be calibrated for measurement accuracy, and the sieves are available with a certificate of compliance (ISO 3310 or ASTM E11), an inspection certificate, or a calibration certificate. The company’s sieving products are also designed for durability and ease of use, delivering precise and reliable results in industrial applications.

Vibratory Sieve Shaker AS 200 control. Image Credit: RETSCH GmbH

Figure 4. Sieving of polyamide granulate using AS 200 control, three sieves and a collecting pan to determine the proportion of granules larger than 3 mm or smaller than 2 mm. The sieving was performed at an amplitude of 1.3 mm for a total of 5 minutes, using 10 second intervals. Image Credit: RETSCH GmbH

Conclusions

Structured sample preparation is crucial for success in polymer processing, whether for recycling, material development, or quality control. Plastic components are converted into fine, precisely defined powders and granulates through grinding, sieving, and mechanochemical methods.

Retsch’s systems, including the SM 300, ZM 300, CryoMill, and AS 200 series, elevate research, development, and production capabilities. This innovative approach transforms plastic waste and raw polymers into the materials of tomorrow, paving the way for advancements that promote sustainability and versatility in our future.

This information has been sourced, reviewed and adapted from materials provided by RETSCH GmbH.

For more information on this source, please visit RETSCH GmbH.