Effective thermal management is critical in modern electronics for maintaining component performance, life-time, and reliability.

While thermal grease, also referred to as thermal paste or thermal compound, has traditionally been the preferred option, advancements in thermal interface materials (TIMs) have introduced alternatives that overcome many of the challenges associated with thermal grease.

This article compares several TIM options, including thermal phase change materials (PCMs), graphite interface pads, and thermal foils, each offering distinct advantages over conventional thermal grease.

Image Credit: Materials Direct

Thermal Grease: Strengths and Drawbacks

Thermal grease is a viscous material, usually applied with a syringe or applicator, to create a thermal bridge between components. It can be effective at transferring heat, but its drawbacks become apparent in applications that demand consistency and ease of handling.

Even application is difficult, which increases the risk of poor contact areas that compromise thermal performance. Its thick, sticky nature also makes it messy to work with, raising the chance of contamination. On top of this, achieving the correct amount is challenging - too much or too little grease can both reduce conductivity.

Reliability over time is another issue. In high-temperature environments, thermal grease can degrade as oils and compounds evaporate. This process often leaves behind silicon oxide deposits on nearby surfaces and components.

Because silicon oxide is electrically conductive to a degree, this poses particular risks in hermetically sealed systems. As the grease dries out, its thermal performance diminishes, making it unsuitable for applications where long-term stability is critical.

As the demand for consistency and durability grows, engineers are increasingly looking to alternative thermal solutions that offer cleaner handling and more reliable performance over the long term.

Thermal Phase Change Materials: Precision Under Heat

Thermal phase change materials (PCMs) provide a reliable alternative. These compounds are engineered to change at a specific temperature, transitioning from a solid to a soft or viscous state as the temperature increases. This distinct property allows PCMs to fill in surface irregularities and air voids, ensuring uniform contact without the risk of mess or uneven application associated with thermal grease.

As PCMs soften, they self-level, reducing the risk of pump-out during thermal cycling and enhancing long-term stability. Particularly, their resistance to drying ensures that they maintain their thermal conductivity even in high-temperature conditions. This makes PCMs especially suitable for demanding, high-performance applications where consistent and reliable thermal management is crucial.

Image Credit: Materials Direct

Graphite Interface Pads: Durable and Effective Heat Spreaders

Graphite interface pads, produced from natural or synthetic graphite with high thermal conductivity, are another advanced thermal solution. Unlike other TIMs that primarily conduct heat vertically, graphite pads spread heat horizontally across surfaces, effectively managing hotspots in compact devices.

These pads are pre-cut to specific shapes, allowing clean, simple handling and consistent application without mess. Furthermore, graphite’s inherent stability ensures resistance to both drying and pump-out during thermal cycling, making it highly reliable for long-term use. With a high in-plane (across the material horizontally) thermal conductivity, graphite interface pads are perfect for applications where effective heat spreading is critical.

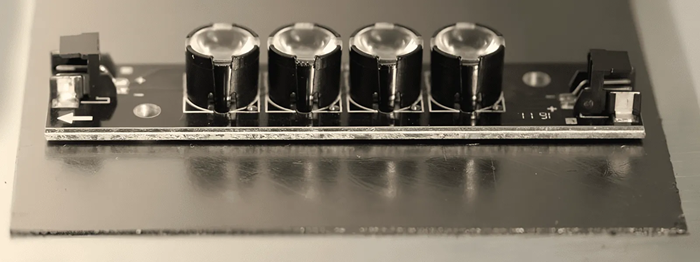

Image Credit: Materials Direct

Thermal Foils: Clean, Consistent, and Durable

When electrical isolation is needed alongside efficient thermal transfer, thermal foils - also known as thermal interface pads - provide a clean, reliable alternative to thermal grease.

These foils are typically composed of three elements: a carrier film (often glass fiber), a filler such as ceramic particles (e.g., boron nitride), and a silicone or acrylic binder. This construction delivers both thermal performance and ease of use. Because they can be manufactured to the exact shape required, thermal foils enable quick, clean application, making them particularly well-suited to high-volume manufacturing.

Unlike grease, thermal foils maintain a consistent thickness, ensuring uniform heat transfer and minimizing the risk of air gaps. Their durable composition also eliminates common issues such as drying out or pump-out, making them an excellent choice for applications that demand long-term reliability.

Image Credit: Materials Direct

Conclusion

Each thermal interface material provides distinct benefits over conventional thermal grease, addressing problems of uneven application, contamination, and degradation.

Whether the requirement is consistency, simplified handling, or increased durability, these alternatives offer dependable solutions that fulfill the requirements of contemporary thermal management.

Acknowledgments

Produced from materials originally authored by James Stratford, Technical Director, Universal Science and Materials Direct.

This information has been sourced, reviewed and adapted from materials provided by Materials Direct.

For more information on this source, please visit Materials Direct .