X-ray product inspection is an advanced technique used to ensure the safety and quality of food products in the food and beverage industry.

The primary application of this technology is to scan and detect any foreign objects or contaminants in goods, such as metal, glass, or plastic, thereby protecting consumers' safety and the manufacturer's brand.

There are further applications where advanced X-ray technology can be used to ensure that specified visual quality parameters are met during the manufacturing process.

This technology is Artificial Intelligence (AI), which in manufacturing refers to the use of modern technologies and algorithms to improve many parts of the production process.

Integrating AI involves using intelligent systems and robots to accomplish tasks that have traditionally required human intellect, such as perception, reasoning, learning, and decision-making.

AI in manufacturing seeks to optimize production, increase efficiency, reduce costs, improve product quality, and enable machine learning, computer vision, robots, and other AI technologies.

It can result in enhanced productivity, improved safety, and the ability to respond to changing market conditions.

This article will look at the integration of AI with X-ray inspection software and how it benefits the food manufacturing industry, focusing on two specific applications: cheese production and bakery bread packaging.

X-Ray Inspection and AI

The Thermo Scientific™ Xpert™ C and Xpert C HD series are powerful X-ray product inspection systems designed for industrial applications.

These devices use cutting-edge technology to deliver high-performance and dependable inspection capabilities. Xpert C is primarily designed to inspect bags, boxes, and other packaged products, whilst Xpert C HD is intended to handle larger and heavier products.

The Xpert software detects and identifies foreign contaminants and flaws using complex algorithms and image processing techniques. It can be adapted to support a variety of applications. The Xpert software can be extended with a new AI module for detecting and categorizing product images.

This AI software module runs on the same PC as the X-ray apparatus. Once a trained model is included in the X-ray software, it can efficiently analyze and classify objects depending on predetermined thresholds, such as whether they are compliant or non-compliant.

Optimizing Performance: Exploring the AI Module in the Software

Thermo Scientific's Xpert AI software module uses artificial intelligence to improve the imaging process. In addition to typical image processing techniques, it uses advanced algorithms that examine pixels and gray levels commonly found in conventional software.

The AI system will divide each scanned image of the product into unique classes, with a minimum of two and a maximum of five. For example, a product can be classified according to its shape, such as square, rectangular, round, oval, or triangular, resulting in the greatest number of classifications.

Alternatively, the minimum number of classes could be classified as compliant or non-compliant. To guarantee that this module functions properly, Thermo Scientific’s application team will run one or more training cycles for each product/recipe. During these training cycles, they will use the classified images provided by the customer.

AI Learning Process

The software can use a different model for each product file or recipe that is set up. The AI algorithms for AI-guided Xpert software are trained using an X-ray image collection. This usually involves a four-step process:

- Data Collection: The customer provides a diverse set of X-ray images. The customer divides these images into distinct "classes," which normally range between two and five. These categories correspond to various images with distinct details. For example, when identifying chicken parts, the options could include "full chicken," "breast," "wing," and "leg." This dataset is then used as the foundation for training the AI model.

- Machine learning process: The obtained dataset is then used to train the AI model using machine learning. This involves feeding labeled examples of X-ray images to AI algorithms, which then identify the necessary features or defects. The AI model learns from these examples and adapts its internal parameters to identify and classify comparable traits or flaws in new, previously unseen X-ray images.

- Customer testing: The customer receives the AI software model and tests it on their production line. Additional images are then supplied to the technical team to improve image accuracy.

- Optimized software: The software has now "learned" more images from the previous phase. An optimized software model will be finished for production use and sent to the customer.

The learning process is designed to enhance the AI model's accuracy and performance, enabling it to effectively recognize and classify specific features or anomalies in X-ray images during real-time inspection.

AI Applications

Artificial intelligence has proven to be advantageous in several applications where previous image processing methods were too complicated or where it was difficult to establish the best path to take.

Consider two applications: cheese production and bread packaging for bakeries.

Cheese Evaluation Application

The AI program was essential for a cheese manufacturer to categorize cheese goods. The manufacturer had to determine if cheeses were mature or not based on variables such as the quantity, shape, size, distribution, and positioning of holes.

Initially, a human inspector would evaluate the products by visually inspecting X-ray images on a screen. However, due to the product's intrinsic variability and the intricacy of the evaluation factors, typical analytical inspection procedures proved impractical.

To overcome this issue, the AI module was trained to categorize the cheese into five unique groups, simulating the actions of a human operator.

The categories were separated into A1, A2, and B (Figure 1) for cheeses that are not yet ready and require additional time to mature, and C and D (Figure 2) for cheeses that are fully matured and ready for consumption.

Figure 1. Images A1, A2, and B (left to right) are classified as not fully matured cheeses. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

To conduct an early evaluation of the artificial intelligence systems, a total of 500 cheeses were studied. The sample of 500 cheeses included 100 examples from each of the five classes (A1, A2, B, C, D). Table 1 shows the results of this initial classification test on a fairly complex cheese application.

Using AI technology, the cheese company was able to automate and streamline the cheese classification process, surpassing the constraints of manual inspection methods.

This resulted in greater productivity, precision, and consistency in categorizing and rating cheese maturity, ensuring that their consumers receive only the highest-quality cheese products. This dedication to quality helps to improve their brand recognition and ensure client satisfaction.

Figure 2. Images C and D (left to right) are classified as fully matured cheeses. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Table 1. Initial assessment using 500 images, where a total error of 1.2 % was captured. Source: Thermo Fisher Scientific – Production Process & Analytics

| |

Images |

Detected as fully

matured cheese |

Detected as not fully

matured cheese |

Error % |

| A1 products |

100 |

0 |

100 |

0 |

| A2 products |

100 |

0 |

100 |

0 |

| B products |

100 |

5 |

95 |

5 |

| C products |

100 |

99 |

1 |

1 |

| D products |

100 |

100 |

0 |

0 |

Bakery Bread Application

A baked products firm had an application that required AI software to verify the correct placement of panettone in its final packaging.

The purpose of this application was to identify and reject any panettone that had been rotated 90 ° inside the carton box. Due to the product's varying size and shape, a traditional approach was impractical because it would fail to account for the potential variations that occur over time.

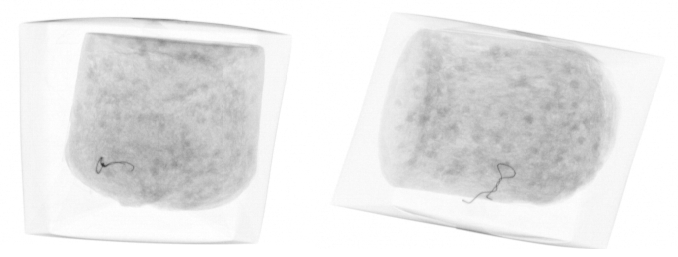

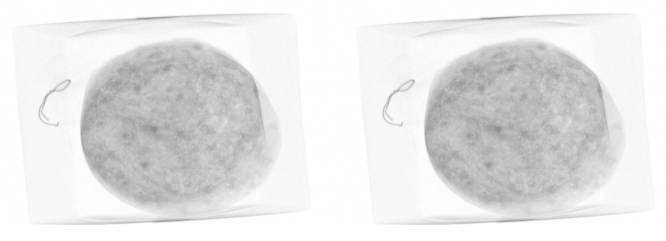

To address this issue, the AI model was trained to divide the product into two categories: "A" represents a product that does not satisfy the standard (a product rotated 90°), and "B" represents a product that does meet the standard (a product aligned perfectly in the box).

Figures 3 and 4 below illustrate instances of X-ray images provided by the customer and used in the AI learning process.

Figure 3. Images of product that does not meet standard (rotated 90 °). Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Figure 4. Images of products that meet the standard (aligned correctly). Image Credit: Thermo Fisher Scientific – Production Process & Analytics

An initial evaluation of the artificial intelligence algorithms was carried out using 1,994 photographs from the manufacturer. The results are given in Table 2, which shows an evaluation error of 0.11%. This error rate is consistent with the production line's error rate of 0.10%.

Table 2. Initial assessment using 1,994 images, where a total error of 0.11 % was captured. Source: Thermo Fisher Scientific – Production Process & Analytics

| |

Images |

Product evaluated as

good from software |

Product evaluated as

bad from software |

Evaluation

error |

| Good products (B) |

1,894 |

1,892 |

2 |

0.11% |

| Bad products (A) |

100 |

0 |

100 |

0% |

The use of X-ray and AI technology has helped the panettone producer significantly reduce quality control and inspection time.

This system results in the rapid and precise assessment of product quality, ensuring that the product maintains its desired position when it enters the market, maintaining the brand's reputation.

This information has been sourced, reviewed, and adapted from materials provided by Thermo Fisher Scientific – Production Process & Analytics.

For more information on this source, please visit Thermo Fisher Scientific – Production Process & Analytics.