A Citrine Informatics customer manufactures formulations for semiconductor photolithography. As silicon chips shrink in size, this customer’s products must become increasingly performant.

This article describes how Citrine Informatics's customer used the Citrine Platform to develop cutting edge formulations.

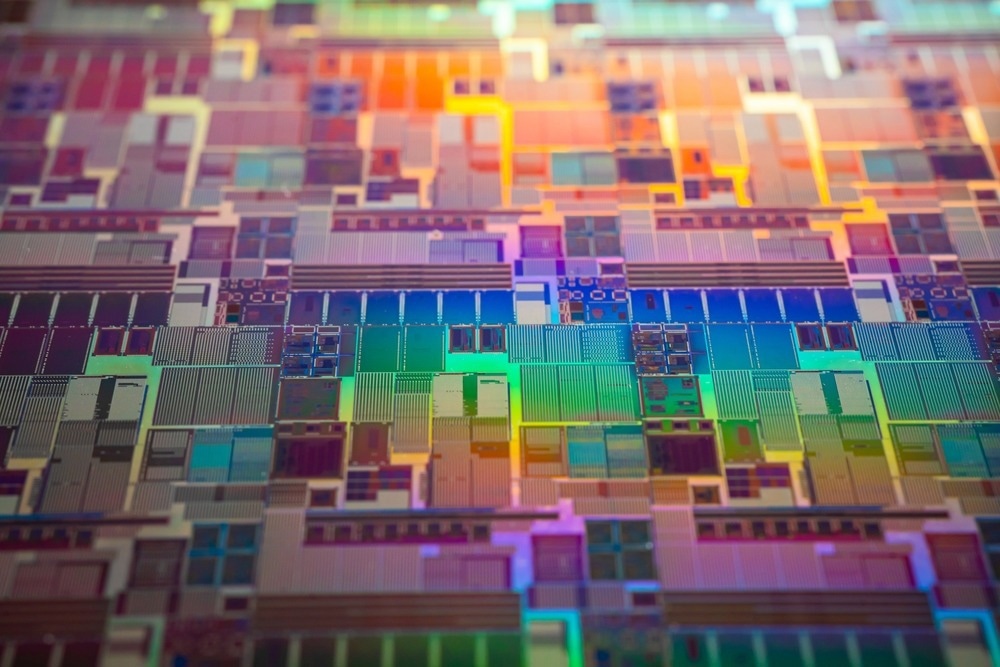

Image Credit: sasirin pamai/Shutterstock.com

The Problem

Semiconductor companies must constantly push the limits of science to produce smaller, faster processors.

Meeting these requirements depends on optimizing photolithography, a process that uses UV light to selectively remove a formulation from a silicon wafer to create patterns.

The pattern must be properly defined, which is determined by both the photosensitive molecules and the formulation's composition, as well as the method of application.

To meet industry requirements, Citrine Informatics' customer needed to create a formulation that met extremely stringent standards that had never been reached before.

The Process

Before commencing the project with Citrine, the customer had generated and tested 100 formulations and opted to do 200 trials using traditional methods and 200 using Citrine to recommend experimental possibilities (an excellent way to validate the use of AI).

In addition to the 100 initial datapoints, the Citrine Platform automatically provided extra chemical data for each molecule in each composition.

A sequential learning (SL) technique was used, where experiments were conducted in batches, and the results of each batch were used to retrain the AI model, which then suggested the next batch.

The researchers tracked what the AI model identified as significant for forecasting in each round of SL using the platform's "Feature Importance Table" to determine if it was actually learning over time.

The Outcome

The traditional experimental procedure did not achieve all of the desired qualities simultaneously. The Citrine Platform proposed previously unknown areas of inquiry, learned from the findings, and met the objectives.

- Citrine Informatics’ Platform proposed candidate materials that broke through the existing Pareto front and met all targets. The Citrine Platform provided the top nine outcomes out of 400.

- The customer saw this breakthrough as an opportunity to continue innovating and being competitive.

- The next stage is to integrate the Citrine Platform into daily workflows, allowing the R&D team to quickly respond to customer requests with a formulation that can be modified in collaboration with the customer.

This information has been sourced, reviewed, and adapted from materials provided by Citrine Informatics.

For more information on this source, please visit Citrine Informatics.