Though they are crucial for energy storage, the increasing energy density of lithium-ion batteries raises substantial safety concerns. Reports of thermal runaway incidents emphasize the urgent need for improved techniques to study and mitigate these hazardous events.

Gas evolution during thermal runaway is a key challenge in battery safety research, since conventional methods like gas chromatography operate in settings that do not truly reproduce high-temperature and high-pressure conditions. This article describes a new integration of adiabatic calorimetry (BTC-500) and high-pressure mass spectrometry for characterizing gas evolution during lithium-ion battery thermal runaway.

This approach enables high-frequency gas composition analysis under extreme conditions and in real time, overcoming the drawbacks of legacy techniques for gas analysis. Compared to standard gas chromatography, which requires offline analysis and sample transfer, in situ mass spectrometry provides clear and dynamic measurements of evolving gases. This enables a more comprehensive comprehension of reaction pathways, such as the recognition of transient species that could be missed otherwise.

The study identified crucial differences in gas compositions between two types of battery, demonstrating the variability in decomposition reactions and gas evolution mechanisms. This method advances research into battery safety by providing real-time insights into the chemical processes that occur during thermal runaway.

An improved comprehension of gas formation dynamics can in turn influence the creation of safer battery materials and improve models for predicting failure scenarios. These results demonstrate how high-pressure mass spectrometry, when combined with adiabatic calorimetry, can improve safety tests and speed up the creation of next-generation lithium-ion batteries.

Battery Safety in Modern Technology

Battery safety has come to the forefront of research as a result of the growing global demand for increasingly powerful and energy-dense lithium-ion batteries. Reports of fires and explosions have frequently been seen in the news, demonstrating the need for improved safety measures.

Such fires are caused by thermal runaways, the process in which exothermic reactions in the battery enter a feedback loop.

The amassing of heat in the battery catalyzes a series of decomposition reactions that release gases and heat. The gases produced in this reaction can be flammable, depending on the type of electrolyte used. When the metal oxides that form the cathode combine with flammable gases and heat, oxygen can be released, which can in turn create ideal conditions for dangerous fires and explosions.

A series of progressively complicated reactions ensue as a lithium-ion battery heats up. At temperatures exceeding 70 °C, lithium salts break down and react with solvents, forming a new Solid Electrolyte Interphase (SEI).

Between 90-130 °C, the SEI layer ((CH2OCO2Li)2) decomposes, releasing heat, and gases like ethylene (C2H4), carbon dioxide (CO2), and oxygen (O2). The anode surface loses SEI protection at around 120 °C, allowing embedded lithium to react with electrolyte solvents, such as ethylene carbonate and propylene carbonate, producing hydrocarbon (CxHy) gases.

The decomposition of electrolytes begins at around 110 °C and continues up to 230 °C, releasing fluoride compounds. At the same time, the separator becomes smaller and melts between 130-190 °C, weakening structural integrity. At 200 to 300 °C, cathode materials break down and release O2, with onset temperatures varying by material: for example,∼150 °C for lithium cobalt oxide (LiCoO2), ∼220 °C for lithium nickel manganese cobalt oxide (NCM811), and ∼310 °C for lithium iron phosphate (LiFePO4).

At temperatures exceeding 230 °C, the binder polyvinylidene fluoride (PVDF) reacts with lithium and decomposes. By 235 °C, thermal runaway occurs, creating gases such as CO2, carbon monoxide (CO), hydrogen (H2), hydrocarbons (CxHy, CxHyOz, and CxHyF), phosphoryl fluoride (POF3), and hydrogen fluoride (HF), while the vaporized electrolyte adds more volatile components, escalating the hazard.

It is important to note that these reactions do not happen exclusively within these given temperature ranges. Rather, as the temperature increases, the reactions become increasingly complex and intertwined.

H.E.L Group’s BTC-500 is a benchtop adiabatic calorimeter developed to enable the comprehensive analysis of the thermal behavior of batteries. It evaluates responses to thermal, electrical, and mechanical stress, providing data on the battery’s safe operating limits.

The aim of this work is to study the gas evolution profile of two batteries using an innovative combination of adiabatic calorimetry (BTC-500) and gas analysis using in situ mass spectroscopy.

Material and Methods

Lithium-ion batteries

Two LiFP batteries were used in this experiment, one with a capacity of 151 Ah and one with a capacity of 177 Ah. Both were at 100 % SOC before the study.

Adiabatic Calorimetry (BTC-500) equipped with High-Pressure Mass Spectrometry

A mass spectrometer was attached to a BTC-500 (H.E.L Group, Hemel Hempstead, UK) in a manner that allowed the sampling of the gases produced during the LIB thermal runaway. This allowed gas with high-frequency data acquisition (50 ms per mass number) to be analyzed at high temperature and high pressure (8 bar).

Figure 1. BTC-130 attached to mass spectrometer. Image Credit: H.E.L Group

The batteries were put through thermal runaway using the Heat-Wait-Search plan. When the battery entered the thermal event, an in situ online analysis was performed, giving real-time observations of the chemical reactions that occurred. Recurring online sampling was conducted, taking samples at predefined intervals during the reaction. In addition, gas samples were compiled after the thermal runaway finished, meaning retrospective analysis could be performed on transient reactions that may have been missed.

Results and Discussion

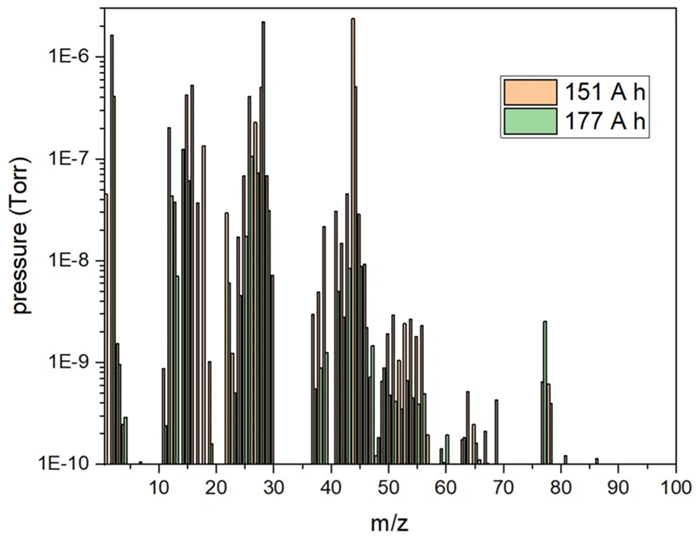

Figure 2. The composition of the gas produced by two batteries (151 A h and 177 A h) during thermal runaway in a BTC-500. Image Credit: H.E.L Group

Figure 2 shows the gas produced by two different types of battery. After the thermal runaway of a 151 Ah cell, a large amount of CO2, H2, CH4, C2H4, CO, and small amounts of sulfur dioxide (SO2) and mercaptamines were identified. After the thermal runaway of a 177 Ah cell, a significant amount of CO, CO2, H2, and small amounts of toluene, trimethylamine N-oxide, and long-chain hydrocarbons were detected.

Limitations of Conventional Methods: Currently, gas chromatography (GC) is the most commonly utilized gas analysis technique. However, GC requires analysis at relatively low temperatures and pressures, making it unsuitable for the evaluation of gas compositions in high-temperature and high-pressure settings.

Advantages of In Situ Online Analysis: The in situ technique enables the taking of measurement pre-, during, and post thermal runaway, reflecting the chemical states and reaction processes in real time. This approach provides a more detailed understanding of the different chemical reactions that occur during each stage of a thermal runaway.

This collaborative approach has introduced a high value feature through the integration of high-pressure mass spectrometry (MS) with H.E.L’s BTC series, enabling high-frequency data analysis at 50 ms per mass number, and offering gas analysis under high-pressure and temperature conditions.

Conclusion

Thermal runaway is a key focus in research surrounding lithium-ion battery safety. H.E.L BTC-500 Adiabatic Accelerating Rate Calorimeter, equipped with an in situ mass spectrometer (MS), enabled real-time, high-frequency gas composition analysis under conditions of extremely high pressure and temperature. This enhances engineers’ and researchers’ abilities to monitor and evaluate gas evolution during lithium-ion battery thermal runaway events.

Acknowledgments

Produced using materials originally authored by Dr. Mario Toubes-Rodrigo, Dr. William Yao, and Carl Chen from H.E.L Group.

This information has been sourced, reviewed and adapted from materials provided by H.E.L Group.

For more information on this source, please visit H.E.L Group.