Accurate and reliable XRF analysis begins with choosing the right sample preparation technique, because the selected technique will determine the results’ accuracy, repeatability, and overall quality.

Image Credit: Matt_Turner/Shutterstock.com

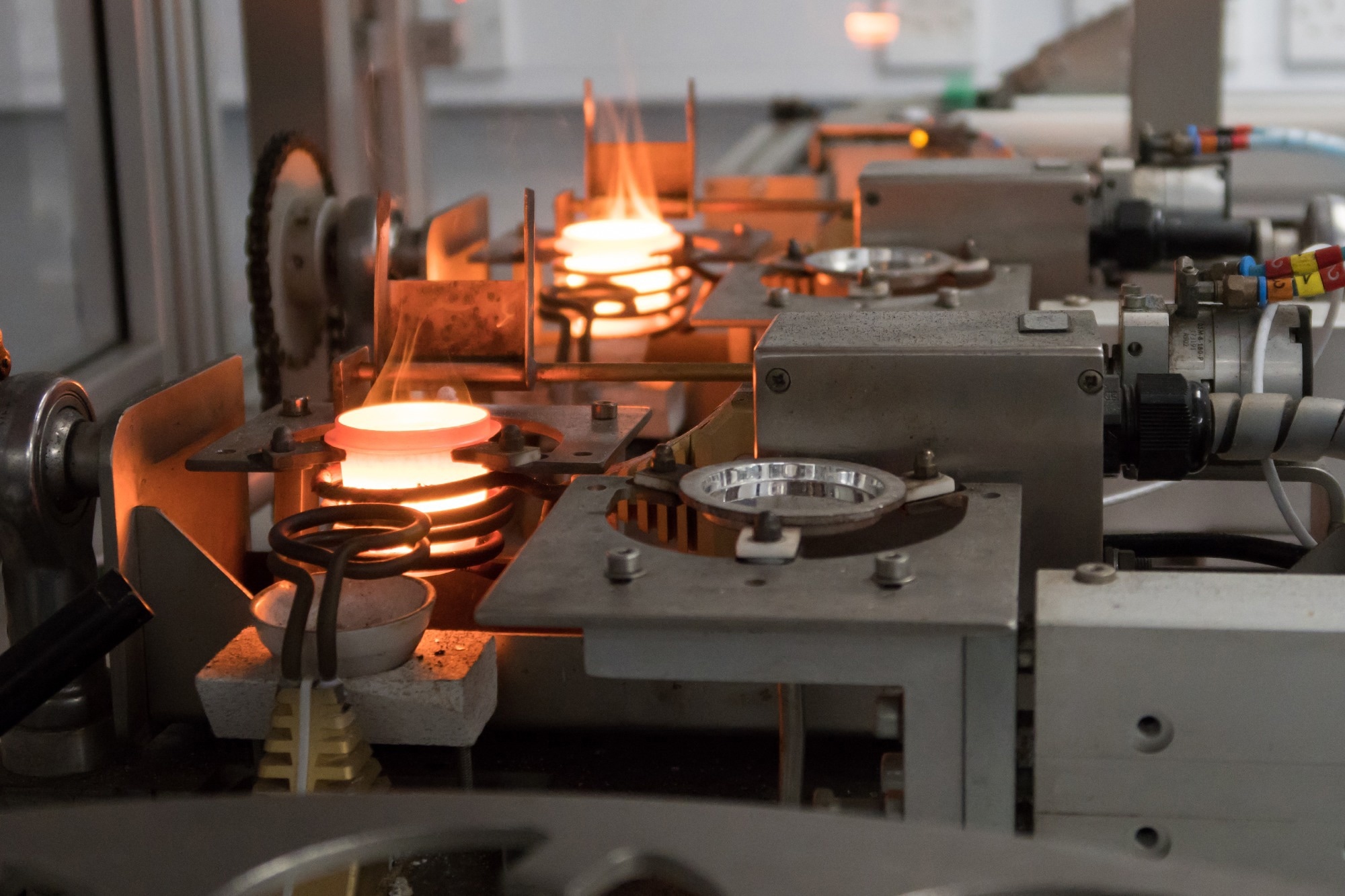

Fusion bead preparation is typically preferred over other available methods like pressed pellets and loose powders, due to its ability to deliver high-precision results by completely dissolving the sample into a stable glass matrix.

Using this type of sample preparation correctly reduces matrix effects, ensures consistency, and enables accurate quantitative XRF measurements across a diverse array of sample types.

Optimizing fusion-bead preparation is fundamental to ensuring consistent and reliable XRF analysis.

Improving XRF Analysis Accuracy with Fusion Bead Preparation

The effectiveness of any XRF analysis depends on both the instrument used for sample measurement and the quality of the preparation method.

The use of fusion bead preparation results in a chemically stable, glass-like matrix that eliminates many of the variables that affect other techniques, including mineralogical variation, particle size distribution, and surface roughness.

This method fully dissolves the sample into a uniform structure, effectively removing the physical inconsistencies that result in reduced reproducibility, signal scatter, and calibration drift stemming from mismatches between standards and samples.

Fusion bead preparation provides high uniformity, enabling precise, matrix-matched calibration that supports analytical accuracy in XRF analysis, typically within 1 %. This method also yields an interference-free and smooth surface that enhances spectral resolution and lowers background noise.

Fusion bead preparation provides many advantages for XRF analysis, but it is important to consider how this process can be refined and optimized. Careful adjustments at the various stages of fusion bead preparation help to ensure consistent analytical performance, especially when working with variable or complex sample compositions.

Key Optimization Steps for Fusion Bead Preparation in XRF Analysis

1. Sample Conditioning

Reproducible fusion bead formation starts with finely ground samples. These samples will ideally be less than 100 μm in size, to ensure total dissolution during melting. Samples should be dried at 110 ± 5 °C after grinding, then stored in a desiccator to eliminate moisture that could affect the fusion process.

When working with materials containing volatile components, it is advisable to ignite these at 1050 °C to stabilize the sample mass and simplify loss-on-ignition (LOI) correction, which is key to ensuring analytical accuracy.

This combination of steps ensures proper control of moisture content and particle size. These two factors significantly impact the sample-flux mixture’s melting behavior and provide the foundation for consistent, high-quality fusion bead formation.

Establishing these parameters at the outset allows analysts to avoid incomplete fusion, irregular bead surfaces, variability in measurement results, and other issues during XRF analysis.

2. Selecting the Right Flux

Flux selection directly influences bead stability and analytical accuracy, meaning that optimal fusion bead preparation is key to ensuring high-precision XRF analysis. Various flux options should be considered, depending on the samples under analysis:

- Li2B4O7 is well-suited to basic or refractory matrices.

- LiBO2 is preferable when working with acidic or silicate-rich samples.

- Mixed ratios (for example, 66:34) provide the flexibility required for complex compositions.

Flux must be dried at between 100 °C and 120 °C prior to use to remove surface moisture that could result in variability during fusion.

The flux-to-sample ratio will generally be set at 10:1 or 20:1. This directly affects dissolution efficiency, dilution, and matrix matching, all of which can affect calibration accuracy in XRF analysis.

Effectively managing these conditions enables laboratories to achieve stable bead formation, minimize matrix effects, and improve the reproducibility of high-precision XRF analysis.

3. Reagents and Additives

Certain additives are required for high-precision XRF analysis to stabilize the fusion process and improve bead quality.

These include:

- Oxidizers (for example, LiNO3) help to ensure the complete oxidation of samples and prevent crucible attack.

- Releasing agents (for example, LiI) support bead release from molds, though there is a risk of these agents introducing spectral interferences in the iodine/halogen region that must be corrected.

- Modifiers (for example, LiF and La2O3) can be used to adjust melt viscosity and enable more accurate calibration.

It is important that both reagents and additives are measured precisely, as even small dosing errors can impact bead uniformity and compromise the accuracy of high-precision XRF analysis.

Laboratories are advised to standardize dosing procedures and routinely calibrate equipment to ensure consistent handling of reagents and additives. This optimizes outcomes and ultimately ensures reliable fusion bead preparation.

4. Fusion and Casting

Conditions must be carefully controlled during fusion and casting to produce the stable, defect-free beads necessary for high-accuracy XRF analysis.

Fusion is generally performed between 1000 °C and 1200 °C. Agitation is used to remove air bubbles and ensure complete dissolution. Next, the molten mixture is poured into molds preheated to approximately 800 °C. This helps to reduce cracking.

A controlled cooling cycle delivers smooth surfaces and consistent bead quality.

Thorough mixing is performed at each stage to enhance homogenization. This, in turn, improves spectral resolution and lowers detection limits, two key factors in ensuring the optimal fusion bead preparation necessary for high-precision XRF analysis.

Summary

Optimal fusion bead preparation is essential if the full potential of high-precision XRF analysis is to be realized. Refining the key stages of this process establishes uniform bead formation, enhanced calibration stability, and a reduced risk of analytical drift.

XRF Scientific provides a range of tools designed to support this optimization, including high-performance fusion equipment, platinum ware, and certified fluxes, all engineered to deliver consistent, reliable data.

The company’s team of experts is on hand to support improvements in sample preparation, ensuring greater accuracy and reproducibility in high-precision XRF analysis.

Acknowledgments

Produced from materials originally authored by XRF Scientific.

This information has been sourced, reviewed, and adapted from materials provided by XRF Scientific.

For more information on this source, please visit XRF Scientific.