Sponsored by XradiaApr 22 2013

The microstructures of electrodes can impact the performance of battery cells as they play a key role in battery energy, charge times, electrical conductivity and power density. Moreover, these microstructures change over time and with state of charge, leading to microstructural deterioration, which is closely linked with the lifetime of the device.

Significance of 3D Measurements

At present, data available on battery microstructure and its changes during operation, processing and failure is not sufficient. Qualitative microstructural data has been successfully obtained through the use of two-dimensional techniques such as AFM, TEM and SEM. Nevertheless, 3D measurements are essential to determine phenomena like percolation which influences the mobility of the Li-ions through the porous structures and electrically connected solids. 3D X-ray microscopy (XRM) is capable of performing in situ and in operando imaging of battery in order to provide the details of these intricate porous materials and microstructural changes.

Multi-Scale XRM Solutions from Xradia

3D XRM solutions from Xradia are utilized for the quantitative characterization of a single lithium ion battery cathode (LiMn2O4) at different length scales. The microscopes include a synchrotron-based Xradia nanoXCT-S100 which attains 30 nm spatial resolution, the ultra-high resolution laboratory-based UltraXRM-L200 which attains 50 nm spatial resolution, and a laboratory-based VersaXRM-500 system which achieves down to 0.7 µm spatial resolution.

In a study, a multi-length scale approach involving these three microscopes was employed to detect the appropriate length scale for revealing key morphological parameters, such as particle shape and size distributions, pore networks, and features within the particles. The solid versus pore phases were analyzed within each scan by segmenting the 3D image into parts of identical material density utilizing Avizo Fire. The results of the study are listed in the following table:

Table. Results from analyzing the cathode imaging volume using laboratory MicroXCT, laboratory UltraXRM, and synchrotron nanoXCT

| Instrument |

Spatial Resolution (μm) |

Examination Volume (μm3) |

Porosity (%) |

Pore Connectivity (%) |

Geometrical Tortuosity |

Vol. Specific Surface Area (μm-1) |

| MicroXCT-200* |

|

1.0 |

10,434,731 |

36.3 |

99.68 |

2.0 |

0.6 |

| UltraXRM-L200 |

|

0.15 |

75,164 |

38.0 |

99.98 |

1.9 |

1.3 |

| nanoXCT-S100 (SSRL) |

0.030 |

263 |

4.5 |

- |

- |

- |

* MicroXCT is a member of the VersaXRM family of 3D X-ray microscopes

In the quantitative examination of the pore networks, the porosity and pore tortuosity were revealed by the VersaXRM with adequate resolution, thus enabling the measurement of transport properties. The precise particle shapes were revealed by the UltraXRM for advanced electrochemical modeling. The measurements of geometrical tortuosity, porosity and pore connectivity are comparable between the lab-based VersaXRM and UltraXRM, demonstrating that the VersaXRM delivers adequate resolution to study the bulk of pore networks. On the other hand, the measurements of volume-specific surface area are different between the two instruments, signifying that the high resolution provided by the UltraXRM is essential to investigate the precise particle shapes. This result is useful for simulating the electrochemical reactions occurring at the pore/particle interface.

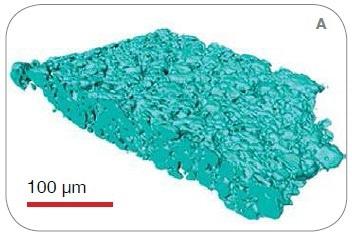

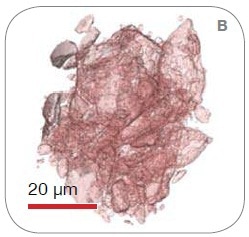

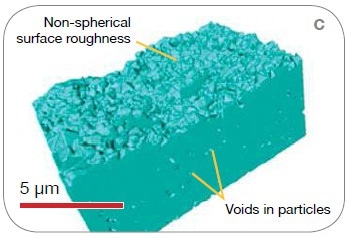

Figure 1. 3D solid-phase renderings from the scans on (A) VersaXRM, (B) UltraXRM, and (C) synchrotron nanoXCT

The electrode’s sub-particle level microstructure was revealed by the synchrotron nanoXCT. The results from the synchrotron examination demonstrate a great discrepancy in porosity. The synchrotron nanoXCT captured the particle-level defects instead of the bulk porosity, as shown in Figure 1C, with the maximum possible resolution. This highest resolution scan exposes a closed porosity of nearly 5% at the sub-particle length scale to the detriment of active material volume.

Conclusion

Using multi-length scale 3D analyses, it may be possible to achieve a detailed micro- to nanostructural model of battery cathode materials. Moreover, the non-destructive nature of X-rays facilitates in situ and in operando studies of battery microstructure to correlate microstructural changes with specific charge cycling parameters as demonstrated by in operand investigations carried out on Xradia XRMs.

This information has been sourced, reviewed and adapted from materials provided by Xradia.

For more information on this source, please visit Xradia.