WDXRF is a flexible technique for analyzing elements in solids and liquids. Elements such as boron and uranium can be accurately, precisely, and reliably examined in various samples. The approach and analytical methods are advanced enough to provide accurate qualitative and quantitative characterization of various materials.

Due to its cost, simplicity, flexibility, and dependability, WDXRF has been incorporated into standard test techniques for analytical laboratories (such as ASTM and ISO requirements), thanks to modern technical advancements. The cost per analysis is unquestionably better compared to several conventional wet chemicals and other spectroscopic procedures.

A Compact and Independent WDXRF Instrument

Thermo Scientific™ ARLTM OPTIM’X spectrometer is a small instrument that offers two power levels and notable analytical features. It is part of the company’s ongoing legacy of innovation and leadership in WDXRF.

- Distinct WDXRF platform with the ability to operate in sequential or simultaneous modes

- Coverage of elements ranging from carbon to uranium, dependent upon arrangement

- Utilizing cutting-edge UCCO (Ultra Closely Coupled Optics) technology, which could boost intensity up to 210% above traditional geometry

- A special small-sized SmartGonio device for sequential analysis

- Analytical flexibility combined with sequential-simultaneous configuration mixing speed

- Multichromators for fast analysis

- Excellent accuracy (short- and long-term repeatability) due to crystals and spectrometer temperature control

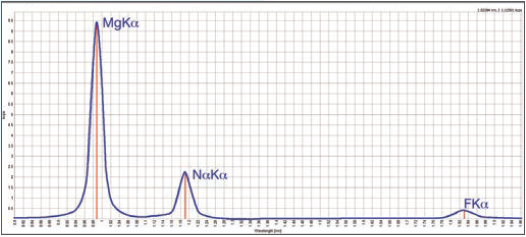

- Superior spectral resolution (~15 eV at Ca Kα and ~30 eV at Mn Kα) from low Z elements to heavy elements in comparison to EDXRF

- The best design (in accordance with ISO or ASTM standards) for a given application with streamlined operation

- Stand-alone and autonomous operation without water cooling

- No gas supply (depending on the setup) and no compressed air

- Simple and direct sample introduction

- Automatic analysis of batches with sample changer

- Small footprint

Excellent resolution compared to EDXRF: Mg, Na and F peaks do not interfere on each other. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

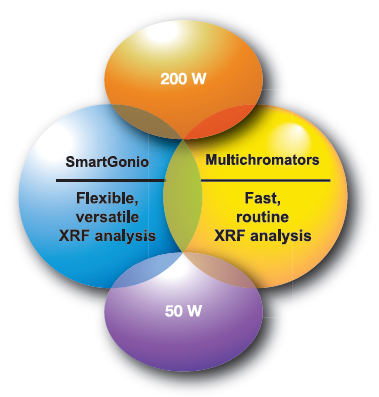

Configuration for Speed and Flexibility

- Using four multichromators, up to eight items can be shown concurrently

- Sequential analysis with the SmartGonio

- Sequential-simultaneous analysis: SmartGonio with two elements on the same multichromator

- 50 W basic or 200 W optional power to produce a 2.5 times quicker analysis

Configuration selected according to application needs. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

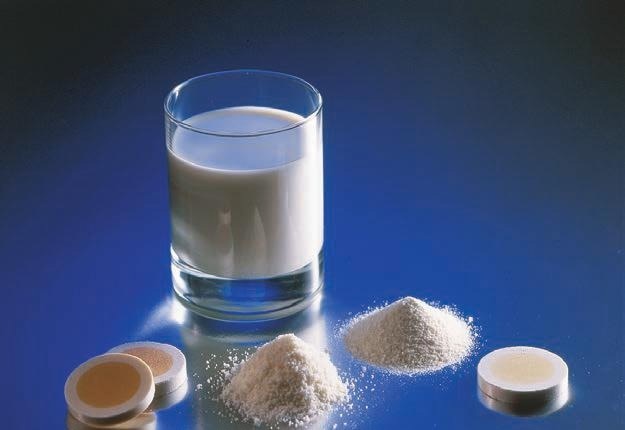

Large Variety of Samples

The ARL OPTIM’X spectrometer can examine several sample types, including conductive or non-conductive solids, liquids, loose powders, pressed pellets, fusion beads, pastes, granules, and coatings. The instrument is customized for specific application requirements.

Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Exclusive UCCO Technology

UCCO–Ultra Closely Coupled Optics

- 200 W performance from 50 W power

- 500 W performance from 200 W power

Whole X-Ray beam exciting the full sample diameter for the highest efficiency: no photon loss during irradiation. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Optimized for Specific Applications

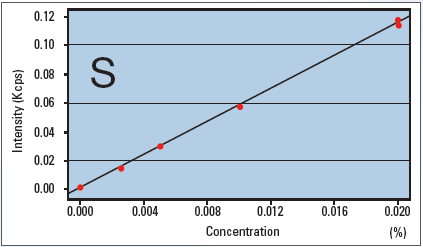

- Petroleum Industry- examination of S (ISO 14596 or ASTM D2622), Pb (ASTM D5059), or other components found in fuels, oils, catalysts, and gasoline. For concentrations ranging from ppm levels up to 5%, it is easy to produce the calibration curve for sulfur in lubricants and gasoline (see Fig. 1). The optimal detection limit of 1.4 ppm in 100 s (or 1 ppm in 200 s) is reached at 50 W. The repeatability test presented in Table 1 demonstrates this positive outcome. The same accuracy is attained in 50 s at 200 W power, and the detection limit drops to 0.8 ppm in 100 s. ARL OPTIM'X Sulfur Analyzer, preconfigured, is available as a turn-key solution

Fig 1. Calibration curve for S in oils and gasoline at 50 W (low concentration range). Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Table 1. Excellent reproducibility for sulfur in oils at 50 W (120 s). Source: Thermo Fisher Scientific - Elemental and Phase Analysis

| Sample |

ppm |

| Cell 1 |

25.4 |

| Cell 2 |

25.7 |

| Cell 3 |

26.4 |

| Cell 4 |

26.0 |

| Cell 5 |

25.0 |

| Cell 6 |

25.9 |

| Cell 7 |

26.7 |

| Average |

25.9 |

| Std. Dev. |

0.58 |

- Major and minor oxides found in raw materials used in cement, clinker, raw meal, and other mining uses, as well as in limestone, sand, feldspar, bauxite, and magnesite. For such materials, the ARL OPTIM'X analyzer exhibits exceptional reproducibility of analysis. The preconfigured ARL OPTIM’X Cement Analyzer is also offered for specific cement applications

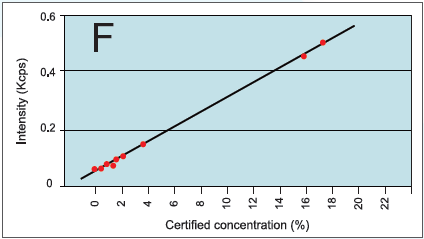

- The preconfigured ARL OPTIM'X Slag Analyzer offers a turn-key solution for metallurgical slag analysis. The calibration curve in Fig. 2 demonstrates that the analysis of F can be performed with the SmartGonio or a fixed channel without any issues. Table 2 displays the great accuracy of ARL OPTIM'X, together with data pertaining to fluorine

Fig 2. Calibration curve for F in slags. Standard error of estimate is 0.2% in a range from 0.1% to 17% . Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Table 2. Repeatability test on a pressed slag sample at 200W (6 consecutive runs). Total counting time 230 s for 13 elements - Fluorine is measured on a fixed channel. Source: Thermo Fisher Scientific - Elemental and Phase Analysis

| Run # |

CaO |

SiO2 |

Al2O3 |

Fe2O3 |

MnO |

MgO |

S |

V2O5 |

TiO2 |

K2O |

P2O5 |

Na2O |

F Mono |

| 1 |

39.58 |

35.37 |

10.05 |

0.984 |

2.42 |

5.43 |

0.954 |

0.209 |

0.811 |

1.506 |

0.641 |

1.4 |

0.493 |

| 2 |

39.61 |

35.33 |

10.06 |

0.984 |

2.43 |

5.43 |

0.948 |

0.213 |

0.812 |

1.512 |

0.642 |

1.41 |

0.484 |

| 3 |

39.63 |

35.41 |

10.05 |

0.993 |

2.42 |

5.44 |

0.946 |

0.212 |

0.819 |

1.511 |

0.646 |

1.39 |

0.477 |

| 4 |

39.55 |

35.38 |

10.07 |

0.985 |

2.42 |

5.43 |

0.953 |

0.213 |

0.812 |

1.514 |

0.646 |

1.40 |

0.491 |

| 5 |

39.62 |

35.4 |

10.06 |

0.993 |

2.42 |

5.44 |

0.953 |

0.210 |

0.811 |

1.508 |

0.647 |

1.37 |

0.471 |

| 6 |

39.57 |

35.37 |

10.06 |

0.987 |

2.43 |

5.47 |

0.954 |

0.209 |

0.815 |

1.513 |

0.645 |

1.41 |

0.486 |

| AVG |

39.59 |

35.38 |

10.06 |

0.988 |

2.42 |

5.44 |

0.951 |

0.211 |

0.813 |

1.511 |

0.645 |

1.40 |

0.484 |

| SD |

0.031 |

0.028 |

0.008 |

0.004 |

0.005 |

0.015 |

0.003 |

0.002 |

0.003 |

0.003 |

0.002 |

0.015 |

0.008 |

| Meas Time [s] |

10 |

10 |

20 |

10 |

20 |

20 |

30 |

20 |

20 |

20 |

20 |

30 |

230 |

- Oxides, both major and minor, in products like refractories, glasses, and ceramics

- Polymers (refer to Table 3), paints, pigments, paper, ferroalloys, silicon, metal sheets, and more products require the monitoring of both major and minor constituents

Table 3. Limits of detection for heavy elements in polymers at 200 W (100 s counting time). SEE: standard error of estimate with ranges from 0 to 500 ppm. Source: Thermo Fisher Scientific - Elemental and Phase Analysis

| |

|

LOD in 100 s |

SEE |

| Element |

Line |

[ppm] |

[ppm] |

| Ba |

Lα |

2.6 |

17 |

| Br |

Kα |

1.0 |

6.1 |

| Cr |

Kα |

0.5 |

3.6 |

| Cu |

Kα |

0.5 |

5.6 |

| Hg |

Lα |

1.2 |

20 |

| Ni |

Kα |

0.3 |

16 |

| Pb |

Lβ |

0.9 |

24 |

| Zn |

Kα |

0.3 |

6.2 |

- The food industry regulates major and minor nutrients in milk powders and cereals. Table 4 shows typical concentration ranges and excellent detection limits for milk powders at 50 W

Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Table 4. Limits of detection (LoD) at 50 W in milk powders prepared as pressed pellets (*cumulative counting time of SmartGonio for Na and Mg). Source: Thermo Fisher Scientific - Elemental and Phase Analysis

| Element |

Analytical device |

Typical ranges |

LoD (ppm in 60 s) |

| Na |

Fixed channel |

0 – 0.03% |

20 ppm* |

| Mg |

Fixed channel |

0 – 0.12% |

11 ppm* |

| P |

SmartGonio |

0 – 1.1% |

4.4 ppm |

| K |

SmartGonio |

0 – 1% |

2 ppm |

| Ca |

SmartGonio |

0 – 1.6% |

10 ppm |

| Fe |

SmartGonio |

0 – 0.33% |

2.1 ppm |

| Cu |

SmartGonio |

0 – 0.012% |

0.6 ppm |

| Zn |

SmartGonio |

0 – 0.2% |

2 ppm |

| Cl |

SmartGonio |

0 – 0.48% |

10 ppm |

| Mn |

SmartGonio |

0 – 0.0023% |

1.2 ppm |

| Se |

SmartGonio |

0 – 3.4 ppm |

0.24 ppm |

(*-cumulative counting time of SmartGonio for Na and Mg)

- Thermo Fisher provides a pre-configured ARL OPTIM'X Uniquantometer for wide-range and unknown material analysis

Full automation with Thermo Scientific ARL SMS-Omega loading system connecting full automatic preparation machines. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

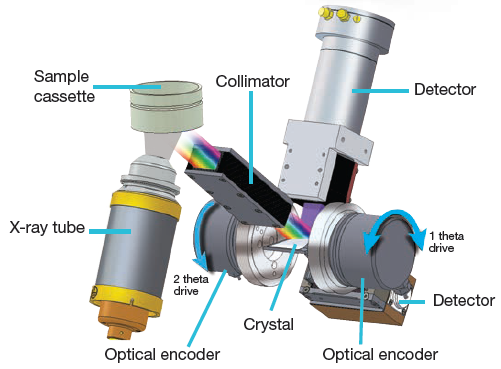

Exclusive SmartGonio – Principle of Operation

Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

- Quantitative examination of elements ranging from F to U based on configuration

- Moiré fringe optical encoders are used for angular positioning, ensuring a Ɵ/2Ɵ connection between the crystal and detector

- Good repeatability and angular accuracy

- No friction, no wear and no maintenance

- Crystal temperature control for optimal analytical stability

- The X-Ray tube’s closest coupling offers the best sensitivity

Top Analytical Software

Instrument Control and Data Handling

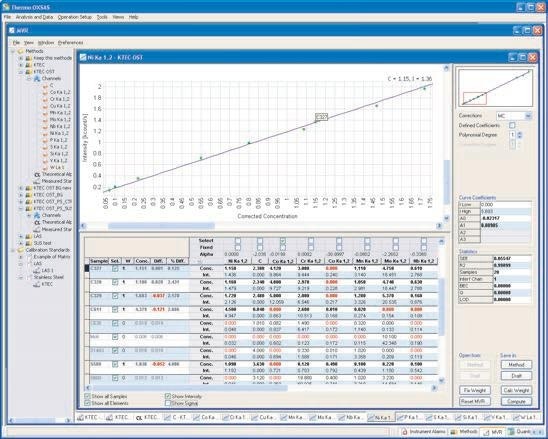

Thermo Scientific OXSAS™ software is state-of-the-art and makes it easy to use the ARL OPTIM’X spectrometer and quickly generate highly accurate analytical findings. Throughout the instrument’s lifespan, OXSAS software is made to adapt to changing client demands by providing them with the most recent solutions, all while running on the Windows® 10 operating system. The product specification document for the OXSAS software contains all the features and information.

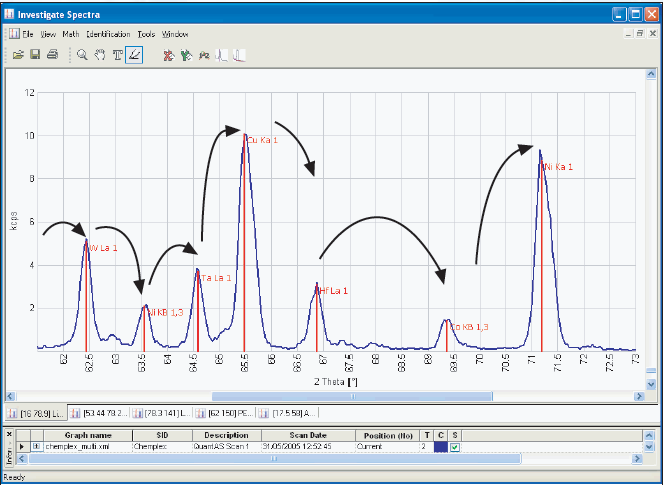

Uniquant

Uniquant uses ‘peak hopping’ to acquire intensities for more than 121 line positions. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

For the ARL OPTIM’X spectrometer, the well-known UniQuant™ program offers “standard-less” analysis for up to 73 elements in situations when certain standards are unavailable, samples are only accessible in limited amounts, or the samples have irregular forms.

Evaluating any specific kind of solid, conductive or non-conductive is possible. It is easy to analyze loose powders, liquids and pastes when the helium environment option is enabled. The Uniquant program also determines the remaining unanalyzed components in the sample, such as organic and ultra-light components. Peak-to-peak hopping analysis offers various benefits over scan-based spectral processing.

- Improved limits of detection

- Optimal counting time for every element

- Sample spinning is used for samples that are not homogenous or to average out the impacts of polishing grooves.

Using the SmartGonio of the ARL OPTIM’X spectrometer, the Uniquant software is completely calibrated and pre-installed in the factory, making it ready for use immediately upon installation at the user’s site. Included are stable samples for long-term setup and upkeep. The ARL Uniquantometer is the preset variant of the ARL OPTIM’X analyzer.

UniQuant is the world’s most renowned standard-less package. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Fast Qualitative Analysis

Step scanning offers 0.001° resolution, which allows for exact peak definition. Continuous digital scanning enables the quick capture of spectra at up to 327 °/min for quick qualitative analysis. The peaks that correspond to the identified items are automatically identified.

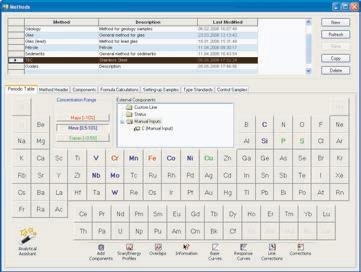

Accuracy Made Easy

The Analytical Assistant helps definition of analytical programs, calibration and instrument use. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

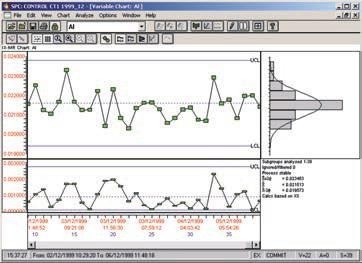

Statistical Process Control – Typical screen. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Analytical programs and calibrations can be quickly and accurately defined with the aid of the online analytical assistant. The different calibration curves are constructed using the multi-variable regression (MVR) tool. Thanks to correction models, the impact of interfering elements in multi-component matrices is reduced, improving analysis accuracy. These types of models are:

- Line overlap correction

- Additive correction on intensities

- Additive correction on concentrations

- Multiplicative correction on intensities

- Multiplicative correction on concentrations

- Multiplicative and additive corrections on concentrations

- The NBSGSC fundamental parameters software, which replicates analytical calibrations for homogenous materials, uses Comprehensive LAchance (COLA) with three-term alphas. The MVR uses the inter-element correction factors—theoretical alphas, now with matrix and LOI/GOI elimination—as known coefficients that are computed. This increases analytical accuracy and reduces the number of standards required to generate calibrations.

Turnkey Calibrations

Ex-works calibrations are available for a range of materials, including:

MVR calibration curve: real concentration vs. intensities. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

- Petroleum industry products using the PetroilQuant program and/ or ASTM & ISO methods

- Iron, hot metal and slags

- Copper, bronze and brass

- Aluminum and alloys

- Ferro-alloys

- Cement and clinker

- Various oxides through the

- General Oxide calibration

- Traces in soils and sediments

- Polymers and coatings

- Minerals such as lime, limestone, dolomite and sands

- Glasses

- Milk powders and cereals

- S and Cl in catalysts

- Requests for analytical specifications can be submitted for any of the aforementioned calibrations as well as bespoke calibrations

Specifications of the Thermo Scientific ARL OPTIM’X XRF spectrometer. Source: Thermo Fisher Scientific - Elemental and Phase Analysis

| . |

. |

| Element range |

Oxygen (Z=8) to uranium (Z=92) with 2 detectors fitted. Oxygen to Iron (Z=26) with FPC detector fitted (Carbon (Z=6) can be fitted as fixed channel) |

| Spectrometer environment |

Vacuum for solids, helium for liquids and loose powders |

| Spectrometer design |

Analysis devices contained in a temperature-controlled vacuum chamber made of grey cast iron |

| Spectrometer arrangement |

X-ray tube inclined at 66° under sample for optimum incidence |

| Spectrometer capacity |

Simultaneous configuration: Four Multichromators (covering eight elements)

Sim-seq configuration: SmartGonio + one Multichromator (covering two elements) |

UCCO

technology |

Ultra Closely Coupled Optics offering largest solid angle for most efficient irradiation of the total sample surface: 50 W power providing excitation similar to 200 W or 200 W power providing excitation similar to 500 W |

| X-ray excitation |

Air-cooled Rh anode end window tube with thin Be window (0.075 mm). Other anodes available on request. 50 W version: Solid-state high frequency generator of maximum voltage 50 kV and maximum current 2 mA (combinations to be chosen to be at 50 W) 200 W version: maximum voltage 50 kV and maximum current 10 mA (combinations to be chosen to be at 200 W). Max. line voltage variation 230 V -15% to +10%. Stability ± 0.0002% per 1% variation |

| SmartGonio |

Fully automatic, gearless, microprocessor-controlled compact goniometer using optical encoders

Total angle range: 0 ˚ -150 ˚ 2 θ (Flow proportional counter: 17 ˚ -150 ˚, Scintillation counter: 0 ˚- 90 ˚ ).

Continuous digital scans: from 0.25 ˚/min to 1200 ˚/min. |

| Multichromator |

Fixed channel using dual curved crystal optics allowing analysis of two elements simultaneously. Sealed detectors available for elements from sodium (Z=11). Flow proportional or scintillation detectors also available depending on element. Dual pulse height integration to discriminate and correct for 2nd order peaks. Note: some elements can only be fitted as single channel monochromator |

| Counting electronics |

Multi-channel analyzer to discriminate peaks of higher energies. Digital Automatic Gain Control (AGC) for pulse shrinking correction.

Automatic dead time correction ensures linearity of response up to 2 Mcps on flow proportional counter and 1.5 Mcps on scintillation counter |

| Sample loading |

Basic: 1 position for cassette or liquid cell. Optional: 13-position autosampler |

| Automation |

ARL SMS-Omega full automation with transport link from/to fully automatic sample preparation machines for pressed pellets or fused beads or solids |

| Sample holders |

Sample cassettes with maximum size of sample: height 26 mm, diameter 52 mm. Liquid cell: height 22 mm, external diameter 40 mm

Exposed opening: 29 mm diameter (basic). Rotation of sample holder in analysis position: 6 to 60 rpm |

| Dimensions and weight |

H 126 cm, W 88 cm, D 82 cm with basic sample loading. System weight: approximately 260 kg |

| Laboratory information |

Optional phone service support through modem connection |

| Power requirements |

1.5 kVA single phase at 50 W; 1.7 kVA single phase at 200 W |

Safety Standards. Source: Thermo Fisher Scientific - Elemental and Phase Analysis

| . |

. |

| Electrical and protection |

EN IEC 61010-1 (Safety requirements for electrical equipment for measurement, control and laboratory use. Part 1: General requirements) |

| Radiation |

Full protection system: Swiss directive ORaP RS 814.501 and German directive RöV BGB1.IS.114 |

| Electro-magnetic immunity |

EN CEI 61326-1 (Electrical equipment for measurement, control and laboratory use – EMC requirements – Part 1: General requirements) |

| European directives |

2006/95/EC (LVD) Low Voltage Directive

2011/65/EC (RoHS) Restriction of Hazardous Substances Directive

2002/96/EC (WEEE) Waste Electrical and Electronic Equipment Directive |