When using the Folding Endurance Testers, a pliable specimen is positioned under a constant tension load. Then, the specimen is folded to an angle of 135° in either direction, at the rate of 175 double folds per minute until the specimen is cut at the crease. A variable folding rate option allows the operator to differ the folding rate between 20 and 175 double folds per minute.

Three Models to Meet Requirements

Model 1 – This applies to leather, fine wire, paper, and other pliable materials with comparatively low elongation features. This machine handles standard 14 cm long by 15 mm wide specimens. Holding jaws are available that will accept specimens differing in thickness from 0.01-0.07 in. Jaw size(s) required should be specified when ordering. The optional centrifugal exhaust fan draws conditioned room air across the specimen and the head to exactly control the humidity and temperature in the fold area, in compliance with TAPPI Method T 511 and ASTM D2176.

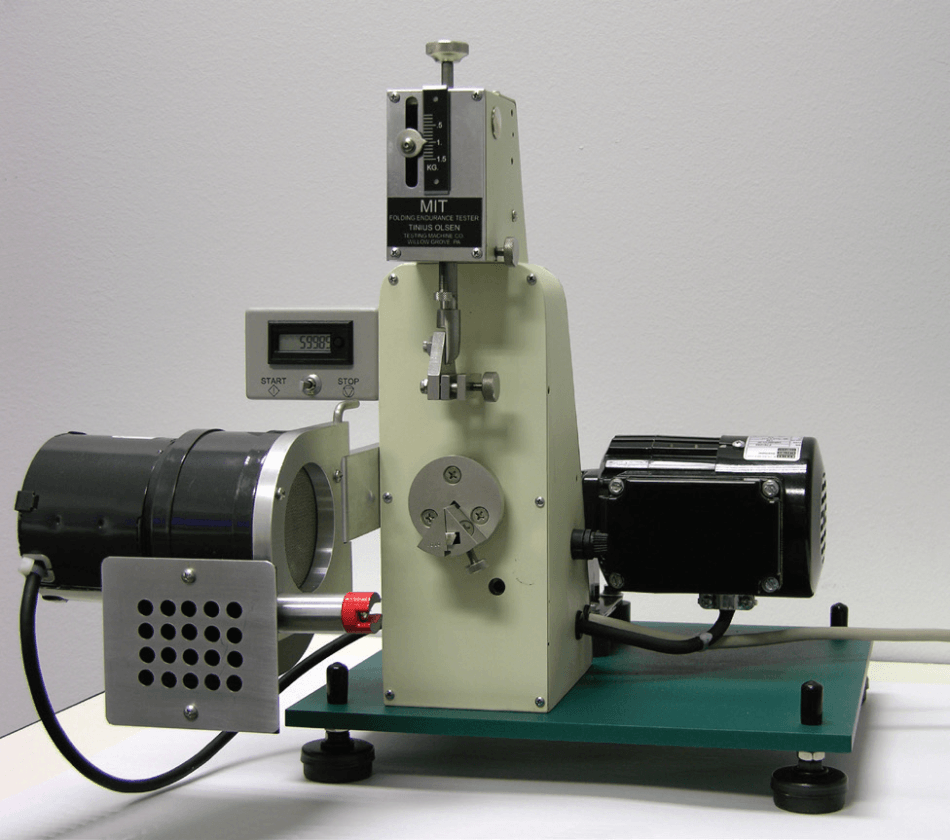

Model 1 Folding Endurance Tester for paper with optional exhaust fan for testing in accordance with ASTM D2176 and TAPPI T 511

Model 2 – For plastics and other materials with comparatively high extents of elongation, this machine offers the same working principles and holding jaw options as Model 1. However, the loading system has been altered to automatically compensate for specimen elongation up to 100% on a 1” gage length. Loads of any preferred magnitude from ½-5 lb in increments of ½ lb can be applied with complete assurance of uniformity throughout the test. It adheres to ASTM D2176 & TAPPI Method T511 standards for high elongation materials.

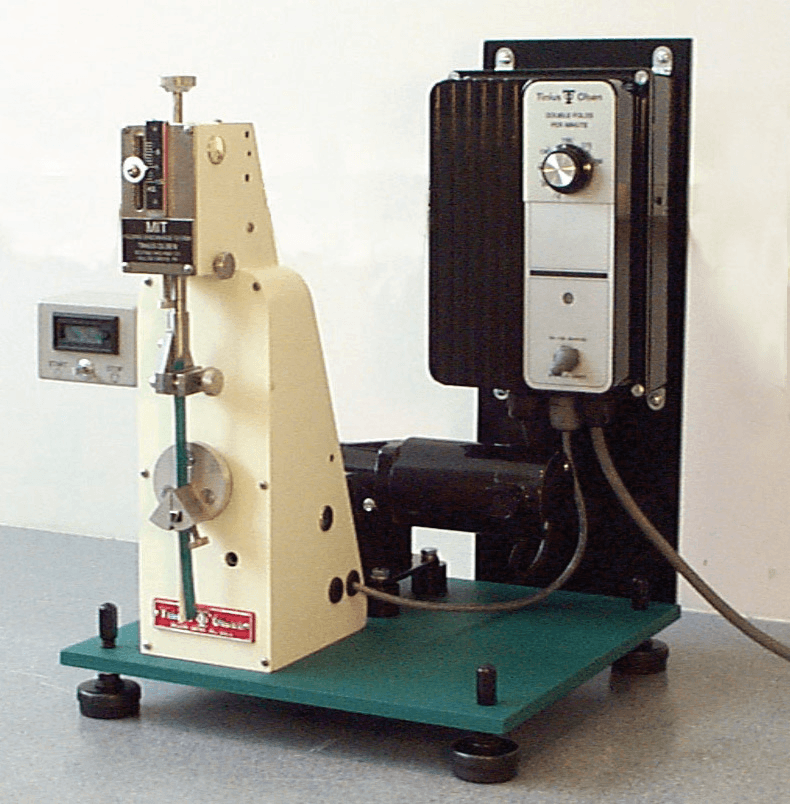

Model 2 Folding Endurance Tester with modified loading system, digital counter and variable speed drive for use on materials with relatively high amounts of elongation

Model 3 Combination Paper and Plastics Tester – For maximum flexibility in testing plastic and paper specimens, this versatile folding endurance tester adds the features and capacities of both Models 1 and 2, as stated above, in a single unit.

Model 1 Folding Endurance Tester with variable speed control