Tinius Olsen is happy to launch the newest addition to its polymer testing line, the MP1200 Melt Flow Tester/Extrusion Plastometer. The MP1200 features the latest in melt flow measurement technology and allows operators to rapidly and easily install and perform melt flow tests, according to ISO 1133-1 and 2, ASTM D1238, and other global and industrial specifications.

The MP1200 comes in two versions: a manual version (Model MP1200), and a motorized version (Model MP1200M). The manual MP1200 has everything one needs (except laboratory balance and weights) to perform an ASTM D1238 Procedure A (manual cut) gravimetric melt flow rate (MFR). Test loads have to be applied manually. The MP1200 can be upgraded with optional features, including ISO 1133 tools and an encoder-based programmable piston displacement transducer (or PPDT for short), for testing according to Procedures B & C (ASTM D1238) or for volume measurement tests (melt volume rate or MVR) and melt density calculations.

Also available are automatic and manual specimen cutting tool attachments, which can be used with certain materials to minimize human involvement with the machine during the test and boost accuracy and repeatability.

The MP1200M is fitted with a motorized weight lifting and lowering device (WLD) that further automates the testing process. The WLD securely and automatically applies test weights to the piston at a user-selected time interval during the test. It is also available with the PPDT and cutter options, as well as the Flow Rate Ratio (FRR) attachment for ASTM D1238 Procedure D for polyethylene and the Purge and Purge/ Clean options.

Both versions feature a redesigned furnace that utilizes a three-zone band heater for unmatched temperature control (+/- 0.1 °C from set point) along the total testing area of the bore, meeting the new requisites stipulated in ISO 1133-2. The furnace also features a fast action die release for easy removal of the die for cleaning after a test.

The MP1200 has a user-friendly color touch-screen LCD display. Users can configure the options available for the machine and program user settings (units, language, alarms, etc). Specific test protocols can be fixed and stored for fast recall when required. When programming tests, operators have the option of choosing which sample identifiers they wish to use from a preloaded list or can create their own identifier. They can also choose which test results they wish to report. Test results are showed automatically at the end of the test and can be saved or printed out to a printer connected to the USB port of the MP1200.

For more advanced data collection, the MP1200 works with Tinius Olsen’s Horizon software, which can store an unrestricted amount of test settings and test results. Test reports and SPC control charts can also be produced.

Specifications

| System |

| Conformance |

ASTM D1238 and D3364, ISO 1133-1 and -2, BS2782, DIN 53735, JIS K7210 |

| Operating temperature |

450 °C max |

| Temperature control |

+/- 0.1 °C |

| Spatial temperature variation |

+/- 0.1 °C |

| Temperature controller |

Three zone PID |

| Temperature sensors |

Platinum RTDs (3) |

| Timer accuracy |

0.001 second |

| Display |

7.1” LCD touchscreen, 800 x 480 resolution |

| Data entry |

Touchscreen display |

| Communications port |

USB |

| Weights |

Stainless steel or Aluminum, +/- 0.5% tolerance |

| PPDT-1200 actuating switch |

| Transducer accuracy |

+/-0.025 mm (+/- 0.001 in) |

| MWLD-1200 motorised weight support |

| Transducer accuracy |

+/- 0.1 mm (+/- 0.01 in) |

| Physical |

| Overall dimensions (WxDxH) |

458 mm/18 in x 394 mm/15.5 in x

521 mm/20.5 in high for basic unit or

762 mm/30 in for motorized unit (to top of weight cage, platform lowered) |

| Net weight |

21 kg/46 lb for basic unit or 32 kg/71 lb for motorized unit, not including weights or options |

| Gross weight |

32 kg/70 lb for basic unit or 43 kg/95 lb for motorized unit, not including weights or options |

| Electrical |

115 or 230 VAC +/- 10% (must be specified at time of order), 50/60 Hz single phase, 500 W average |

| CE mark |

Conforms to all applicable European CE Directives |

Specifications subject to change without notice

Key Features

- Touch-screen control

- Three-zone band heater

- Powerful data analysis and control software

- Quick die release

- Tapered weight design

- USB connectivity

Optional Accessories

Flow rate ratio - Adding this flow rate ratio attachment allows users to establish flow rate using two or three different test loads on a single charge of material.

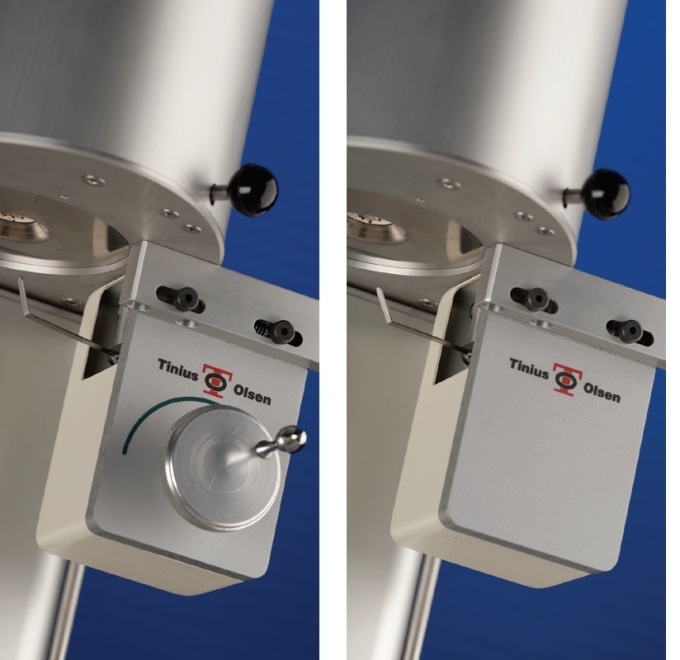

Cut off tools - Two types of cut off tool are offered – a motorized cut off or a manual cut off. The manual cut off (Figure A) features a crank that the operator rotates when prompted; the motorized cut off (Figure B) will automatically cut the extrudate at user preset intervals.

Pneumatic clean and purge - Offered as a purge-only accessory or a purge-and-cleaning accessory, these pneumatically worked pistons are used along with the motorized weight lowering platform for more automated functioning of the MP1200M.

Software

Based upon its long history of delivering solutions to a vast variety of testing problems, Tinius Olsen has developed Horizon, a complete software program that makes testing precise, simple, and efficient. Whether the test sample is metal, composite, paper, rubber, polymer, textile or a micro-component, Tinius Olsen’s Horizon software surpasses beyond data collection and presentation. It will help automate operations, from R&D to the charting and analysis of QC testing. Horizon offers a library of regular, specific, and application-focused test routines that have been developed in close partnership with customers worldwide and to the standards they are using. Among the many beneficial features offered by Horizon are: a test routine library; test, output, method and result editors; real-time multiple machine control; and multilayered security. This software is programed for data acquisition, data analysis, and closed loop control of virtually all Tinius Olsen testing machines.

Horizon also includes the following:

- Generation of user tailored reports

- Ability to recall, replot, and rescale test curves

- Standard SPC programs for X-bar, R and frequency distributions/histograms

- Recall of data that spans various test modules

- Multilingual capabilities

- User-configurable machine parameter and control settings

Horizon is full of capabilities that enhance productivity and enable users to develop, access, and use an advanced, powerful materials testing database. The software employs the latest Windows environments to develop an intuitive user experience. Integral tutorials, online help, and help desk access provide extra user support.

Selectable Weight System

The MP1200 with selectable weight system offers a time-saving and safe way to configure a melt flow test. Weights are held and chosen from weight cylinder holder and are automatically delivered onto the piston in a controlled way. This means users will not have to lift the masses and is definite to increase throughput.

The Weight cylinder holder rotates away from the test area to enable removal of the piston and cleaning.

The required weight is chosen by just pulling the “Plate spade” from the weight cylinder holder and pressing it into the preferred slot thus choosing the required weight.

The MP1200 melt flow tester with assisted weight lift option, available as a standard option for all Tinius Olsen MP1200 models or as a field fitted solution for current motorized Tinius MP1200 units.

Weight configurations based on polymer and testing standard requirement are chosen and applied in a safe way requiring no operator handling.

Common Specifications

| . |

. |

| System Conformance |

ASTM D1238 and D3364

ISO 1133-1 and -2

GB/T 3682

JIS K7210 |

| Operating Temperature |

450 °C |

| Temperature Control |

+/- 0.1 °C |

| Temperature Controller |

Three Zone PID |

| Temperature Sensors |

Platinum RTDs (3) |

| Time Accuracy |

0.001 seconds |

| Display |

7.1” LCD touch-screen, 800x480 resolution |

| Data Entry |

Touch-Screen display |

| Communications Port |

USB |

| PPDT Accuracy |

+/-0.025 mm (+/-0.001 in) |

| Weight Position Accuracy |

+/- 0.1 mm (+/-0.01 in) |

| Weights |

Additive stainless steel with the following weights:

325 g, 1200 g, 2160 g, 3800 g, 5000 g, 10000 g, 21600 g |

| Net Weight |

66 kg (145 lb) including all weights |

| Gross Weight |

72 kg (160 lb) |

| Electrical |

115 or 230 VAC +/- 10%,

50/60 Hz single phase,

500 W average |

| CE Mark |

Conforms to all applicable

European CE directives |

Specifications subject to change without notice.

Tinius Olsen's Extrusion Plastometer – MP1200

Manual MP1200 configured for Method A testing

Home screen for manual MP1200

Home screen for MP1200M motorised

Program creation screen for automatic time flow and time basis tests.

Model MP1200M (motorised) shown with Programmable Piston Displacement Transducer and Automatic Cutter.

Selectable Weight System - Picture 1

Selectable Weight System - Picture 2

Selectable Weight System - Picture 3

Selectable Weight System - Picture 4

Selectable Weight System - Picture 5

Selectable Weight System - Picture 6