The MYTOS laser diffraction sensor offers precise particle size analysis for dry products from 0.25 µm to 3,500 µm in both process environments and automated laboratories. It integrates the reputable core technologies of HELOS laser diffraction and RODOS dry dispersion into a single robust body. When combined with TWISTER – a continuously operating sampling system – a true in-line solution delivering representative results in real-time is realized.

MYTOS can also be operated on-line with TWISTER, MIXER, SCREWSAMPLER, L-probes or existing sample solutions. Successful integration action in automated lab environments is achieved at-line with vibratory feeder VIBRI. Typical MYTOS applications comprise milling operations and spray granulation, for instance.

Possibilities Offered by Process Connection

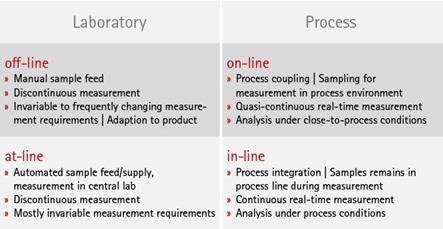

Furthermore, process integration options differ with respect to the type of sampling and sample feeding, closeness to the process both physically and in terms of timing, and the frequency of measurements.

The process-specific laser diffraction sensors find a wide range of applications from cement to pharmaceuticals, from roughest industrial conditions to GMP environments. If required, both systems may be configured for ATEX zones.

Feature Highlights

- Efficient dry dispersion ensuring complete dispersion for fine, even cohesive powders down to the submicron range with MYTOS

- Real-time particle size analysis with laser diffraction of perfectly dispersed powders with up to 2,000 measurements per second

- Representative sampling in or out of process pipes in the diameter range from 38 to 660 mm at product temperatures of up to 150 °C with TWISTER

- Comparability to the established off-line laser diffraction system HELOS | RODOS that share the same core components for a valid method transfer

- Connection to process control systems | TCP/IP, OPC, Modbus, Profibus, PLC signals

MYTOS & Co. Family

The MYTOS family includes different solutions according to their installation environment:

| Sensor |

Versions |

Measuring range/ Modules |

| in-line |

MYTOS & TWISTER |

0.25 µm to 1,750 µm/ 5 |

| on-line |

MYTOS & TWISTER |

0.25 µm to 3,500 µm/ 6 |

| on-line |

MYTOS & MIXER |

0.25 µm to 1,750 µm/ 6 |

| on-line |

MYTOS & SCREWSAMPLER |

0.25 µm to 1,750 µm/ 5 |

| on-line |

MYTOS & Probes |

0.25 µm to 3,500 µm/ 6 |

| at-line |

MYTOS & VIBRI |

0.25 µm to 3,500 µm/ 7 |

| at-line |

MYTOS & VIBRI Module |

0.25 µm to 1,750 µm/ 5 |

| off-line |

MYTOS & VIBRI Module |

0.25 µm to 1,750 µm/ 5 |

Precise Particle Size Analysis - MYTOS & Co

MYTOS with TWISTER | on-line

MYTOS with VIBRI | on-line

MYTOS with VIBRI | at-line