Real-time particle size and concentration analysis in process environments from below 0.1 µm to 3,000 µm is possible with the OPUS from Sympatec. The ultrasonic extinction spectrometer analyses particle size distribution as well as concentration of your suspension, successfully operating in crystallization, grinding and homogenization processes. With various applications, OPUS is repeatedly revealing new insights – not only in production lines but also in pilot plants and lab settings.

Liquid dispersions with a high concentration of solid particles or droplets - often totally opaque - are typically found in production processes. Optical analyzers would require a high degree of dilution, which means not only an extensive preparation effort but changes the original state of dispersion. Ultrasonic extinction delivers superior performance for particle size analysis of suspensions and emulsions. One of its major benefits is the ability to operate in highly concentrated mediums, which typically accompany wet process stages. A solid content between 5 and 50 % by volume is the usual range of concentration: perfect conditions for OPUS, which even may be applied at concentrations up to 70 % by volume – typical for paste-like particulate systems.

Using sound instead of light waves, ultrasonic extinction is independent of the level of transparency. Hence, totally opaque materials like ore slurries, water in crude oil or coke slurries, can be analyzed. Furthermore, paints, sugar pastes, or pharmaceutical suspensions with high solids contents, rank as standard applications for the ultrasonic extinction principle.

In addition, the ultrasonic extinction method allows a rugged and robust probe design that resists typical process conditions. The OPUS probe masters temperatures up to 120°C, pressures up to 40 bar, the entire range of pH-value. It is resistant to aggressive media and abrasive materials. For applications in hazardous atmospheres, an ATEX compliant OPUS version is available.

The control and evaluation software provides calculation and display of all relevant and characteristic size distribution values. The OPUS system is fully compliant with FDA requirements and 21 CFR Rule 11. Adaptation to process control systems is natively supported by TCP/IP, Profibus, Modbus, digital or analogue PLC signals.

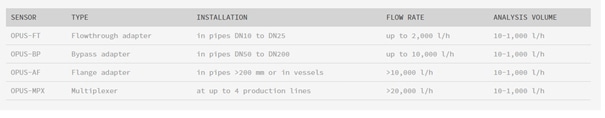

OPUS Series | Process Adaption

The process adaptation of OPUS to vessels or to large pipes is simple and typically uses a 100 mm adapter-flange (AF). For smaller pipes or bypass-lines, specific process adapters are available: e.g., flow-through (FT) or bypass (BP). The sensor may be positioned in a standby rack.

Feature Highlights

- Real-time in-line analysis of high concentrated suspensions, emulsions, slurries or pastes without dilution or sample manipulation

- Particle size and concentration ranging from < 0,1 µm to 3,000 µm

- Robust sensor for industrial processes up to 120 °C | up to 40 bar | pH value 1-14 | IP65

- ATEX optional

- No moving parts

- Soft acoustic method without optical restrictions

- Simple to install and low-maintenance

- Powerful evaluation modes

Particle Size & Concentration Analysis with OPUS

OPUS-AF with adapter flange

OPUS-BP with bypass adapter - Picture 1

OPUS-FT with flowthrough adapter, valve and standby rack

OPUS-FT with flowthrough adapter

OPUS-BP with bypass adapter - Picture 2

OPUS-AF installed in vessel

OPUS-BP with bypass adapter - Picture 3