ECI Technology’s dosing experience of more than 15 years enables the QUALI-DOSE® systems to provide the most novel and comprehensive solutions for handling chemistries in existing Advanced Packaging applications.

The QUALI-DOSE system combines with QUALI-FILL® analyzers from ECI Technology to create a comprehensive online chemical management system—the most robust tool available for facilitating stringent chemical process control.

The QUALI-DOSE system uses smart, versatile algorithms and modes to make up, replenish, or bleed and feed the tank. Powered by quick, efficient dosing, the QUALI-DOSE systems generate no waste and avoid the need for regular maintenance.

Thanks to a system that can offer precise dosing with verification of all the critical components, users can enjoy an unparalleled level of convenience and reliability for running their plating process.

Key Features

- Flexible dosing options are available based on:

- Wafer count

- Analysis results

- Tank level

- Amp/minute

- Concentration levels of target or other components

- Time-based

- All crucial components can be dosed:

- DI water

- Inorganics

- Organics

- Feed and bleed (optional)

- Virgin makeup solution (VMS)

- Automatic standard generation (ASG)*

- Avoids frequent chemical handling and mixing

- Avoids the need to buy high cost standard

- Minimizes CoO, labor and maintenance

- Automatic validation—positive feedback with confirmation of each delivery

- Works in compliance with the industry safety standards: CE SEMI and S2/S8

- Supports multiple tanks, plating tools, and chemistries

- Manual mode for any component

- Can be combined with ECI QUALI-FILL® analyzers or used individually

- Includes NOWPak® reagent delivery system

- Can be combined with pressurized and automated central chemical bulk and blending systems

*Chemistry-dependent

Key Benefits

- Multiple delivery validations

- Accuracy of <3%

- Supports multiple tanks

- Extensive range of flow rates from 20 mL/minute to 5000 mL/minute

- Analyzer-controlled or operates independently

- Multiple dosing modes: dose to target, manual, feed-forward, feedback, time-based, amp/hour, wafer count, etc.

- Automatic verification with bar code eliminates human error

- Recipes provided for new bath make up and replenishment

- Any number of components can be dosed

- Handles bath dump or bleed and feed

- Ability to dose directly from pressurized chemical bulks (central chemical distribution systems)

- Integrates through buffer tank, slip-stream, or direct injection methods

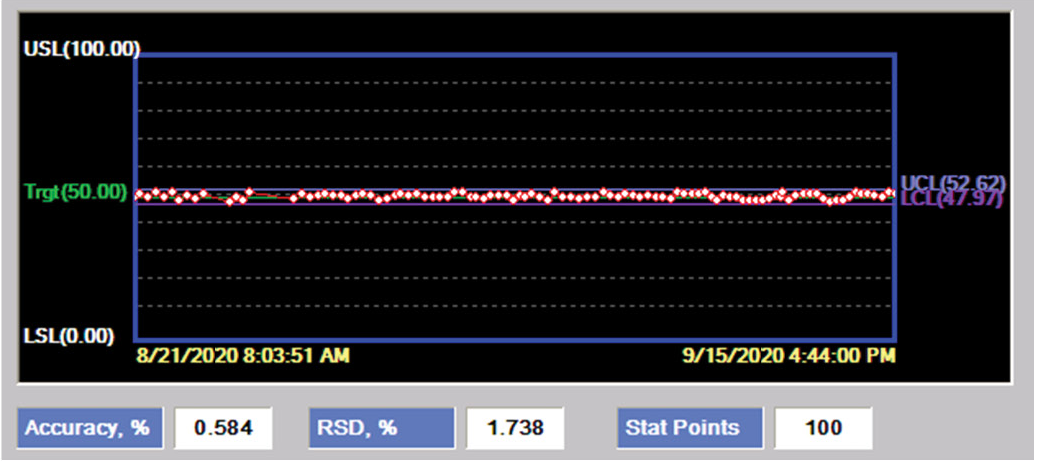

Smaller process variability when using an ECI QUALI-DOSE system

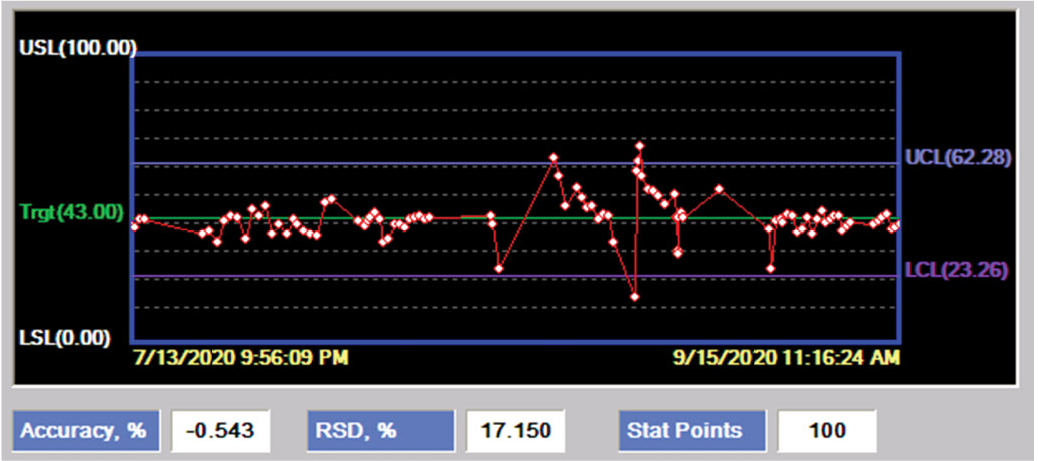

Greater process variability when using an alternative doser

Image Credit: ECI Technology

Technical Specifications

- Dimensions—1829 mm (72″) W x 2061 mm (81.1″) H x 610 mm (24.0″) D

- Compliance standards: CE, SEMI F47, SEMI S2-S8, NFPA 79

- Data communication—Multiple communication protocols such as SECS/GEM, Serial, RS-232 and TCP/IP

- AC—180 to 245 VAC, 50/60 Hz, 15 A