The reflection-configured Digital Holographic Microscope (DHM®) is a non-scanning, non-contact technique for characterizing vibration, static, and dynamic 3D topography.

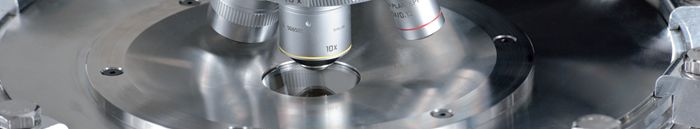

DHM-R measuring through a glass window. Image Credit: Park Systems

Unrivaled Speed

3D Profilometry at Unrivaled Speed

DHM® uses a single acquisition to measure a surface's 3D topographical map; no scanning mechanism is needed. With a camera rate of up to 100,000 frames per second, it offers incredibly quick acquisition, allowing:

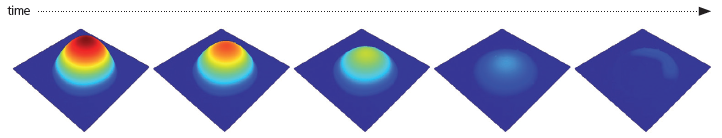

- Analysis of the dynamic behavior of deformable samples in three dimensions

- High-productivity routine inspections

- Quick screen and large surface analysis

- 3D topography capture on the production line without halting the sample

MEMS Analysis, up to 25 Mhz

The DHM® measurements are synchronized with a MEMS device’s excitation signal by the optional stroboscopic unit. This particular collection of data’s analysis yields:

- Time-sequence of 3D topographies

- Frequency resonances and responses

- The vibration amplitude has a resolution of 5 pm for out-of-plane and 1 nm for in-plane displacement

- Characterization of complex motions and sample geometries, including those with holes

Innovation

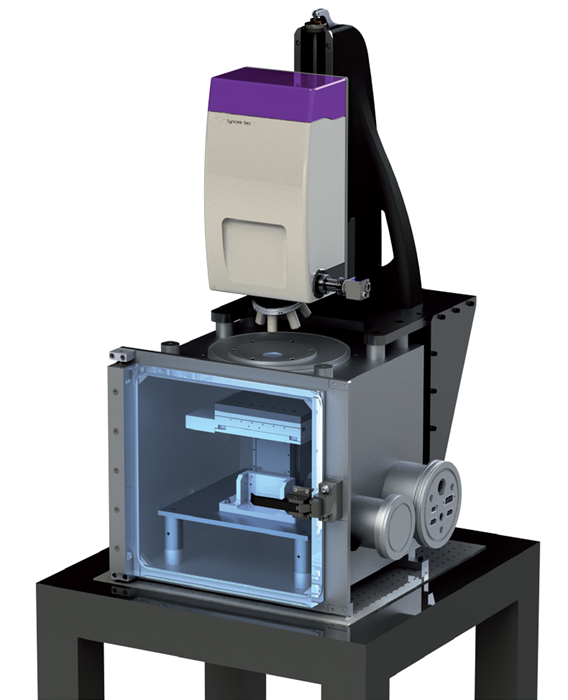

Measure in Controlled Environmental Conditions

DHM®’s optical design ensures high-quality measurements.

- Through glass and immersion liquids

- Within vacuum and environmental chambers with regulated pressure, temperature, humidity, and gas composition

Measure Topography of Transparent Patterns

The following can be measured with the optional DHM® Reflectometry analysis software:

- Topography of transparent structures

- Structured multi-layers with thicknesses ranging from 10 nanometers to tens of microns were analyzed for their refractive index values

- Topography of soft materials and liquids

Time sequence of 3D topographies, limited by camera rate : evaporation of a liquid drop. Image Credit: Park Systems

DHM®

Reflection DHM. Image Credit: Park Systems

Digital Holographic Microscopy (DHM®) is a patented technology. The microscope's digital camera captures holograms caused by interference between the sample's reflected beam and an internal reference beam. The holograms are mathematically processed to produce a three-dimensional optical map of the specimen.

Advanced numerical processing of the recorded hologram makes it possible to conduct crisp focus concurrently or as a post-processing step after measurement, without manually changing the sample’s height.

Based on the number of wavelengths, Reflection DHM® comes in three different versions:

- The R1000 models, utilizing a single wavelength, are optimally suited for measuring smooth surfaces and vibrations.

- To measure complicated or discontinuous structures, R2100 models are set up to measure at two wavelengths concurrently.

- A third source is added to R2100 models to increase measurement capabilities, especially for transparent patterns.

Technical specifications

Source: Park Systems

| System |

| DHM models |

R1000 |

R2100 |

R2200 |

| Number of laser sources |

1 |

2 |

3 |

| Operating wavelength (± 1.0 nm) |

675 nm |

675 nm, 794 nm |

666 nm, 794 nm, 675 nm |

| Laser wavelength stability |

0.01 nm / °C at 675 nm |

| Sample stage |

Manual or motorized XYZ stages up to 300 mm x 300 mm x 38 mm travel range |

| Objectives |

Magnification 1.25x to 100x, standard, high NA, long working distance, water/oil immersion |

| Objective turret |

6 positions |

| Computer |

Workstation with the latest multicore Intel® processor, high-performance graphics card optimized and configured for DHM, with a screen of at least 21 inches and a mouse |

| Software |

Proprietary Koala software based on C++ and .NET

Additional optional software modules are available for advanced analysis |

| Data compatibility |

Measurement data recorded in bin format, exportable in .txt format, recorded and reconstructed images exportable in .tif format or .txt array |

| Performance |

| Measurement mode |

Single wavelength at 675 nm |

Short synthetic wavelength at 4.4 μm |

Long synthetic wavelength at 50 μm |

| DHM models |

R1000, R2100, R2200 |

R2100, R2200 |

R2200 |

| Accuracy 1 [nm] |

0.15 |

0.15 / 3.0* |

20 |

| Vertical resolution 2 [nm] |

0.30 |

0.30 / 6.0* |

40 |

| Repeatability 3 [nm] |

0.01 |

0.01 / 0.1* |

0.5 |

| Vertical measuring range |

up to 200 μm |

up to 200 μm |

up to 200 μm |

| Max. height of steps with sharp edges |

up to 333 nm4 |

up to 2.1 μm4 |

up to 24 μm4 |

| Surface type |

Smooth surfaces |

Complex or discontinuous structures |

Complex or discontinuous structures |

| Vertical calibration |

Determined by an interferometric optical filter, ±0.1 nm |

| Acquisition time |

Standard: 500 μs (optional 10 μs) |

| Acquisition rate |

Standard: 190 fps (1024 x 1024 pixels). (optional up to 100,000 fps). |

| Reconstruction rate |

Up to 25 fps 1024 x 1024 pixels hologram (data analysis dependent) (optional up to 60 fps) |

| Lateral resolution |

Objective dependent, down to 300 nm** |

| Field of view |

Objective dependent, from 66 μm x 66 μm up to 5 mm x 5 mm** |

| Working distance |

Objective dependent, from 0.3 to 18 mm** |

| Digital focusing range |

Up to 50x depth of field (objective dependent) |

| Min. sample reflectivity |

Less than 1% |

| Sample illumination |

Down to 1 μW/cm2 |

| Stroboscopic unit |

Compatibility with single and short synthetic wavelengths |

| Power requirements |

| Input voltage |

85-260 VAC – 50/60 Hz |

| Power requirements |

max. 250 W |

| Dimensions & weight |

| Dimensions (L x W x H) |

600 x 600 x 800 mm |

| Weight |

48 kg |

1 As demonstrated by taking the temporal standard deviation on 1 pixel over 30 measurements

2 Defined as twice the accuracy

3 As demonstrated by taking the one sigma Rq value of 30 repeatability measurements without sample

4 Depends on the laser source(s) and operating wavelength(s)

* With / Without single wavelength mapping

** Objectives specifications on www.lynceetec.com/microscope-objectives

Numerous solutions are compatible with DHM® systems.

Reflection DHM® mounted on a vacuum chamber. Image Credit: Park Systems

- Goals for immersion, cover-glass correction, extra-LWD, etc.

- DHM automation and remote control via a remote TCP/IP module

- Stroboscopic unit for the investigation of MEMS

- Motorized stage for automation and stitching

- Remote TCP/IP module for automating and remotely controlling DHM