Apr 18 2011

The announcement by Intel Corp. and Micron Technology Inc. on April 14, 2011 of a new 20-nm process technology for manufacturing NAND flash memory could signal the end of the low-k hiatus, according to according to the report 300mm/Copper/Low-K Convergence:Timing, Trends, Issues, Market Analysis , recently published by The Information Network, a New Tripoli, PA-based market research company.

"The 20-nm, 8-GB device is sampling now and expected to enter mass production in the second half of 2011," noted Dr. Robert Castellano, president of The Information Network. "We suspect the chip includes air-gaps in low-k dielectric materials based on an IEDM 2010 paper presented by Kirk Prall of Micron Technology and Krishna Parat of Intel that described the interconnect technology used for the companies' 25nm multi-level-cell 64 Gbit NAND. Competitors will need to step-up their technology to compete, utilizing low-k to maximize performance."

Novellus is gearing up for the low-k onslaught. The company unveiled a major redesign of its Vector plasma-enhanced chemical vapor deposition (PECVD) platform, Novellus developed new interface engineering technologies that minimize the damage to ULK materials in the VECTOR Excel modular architecture.

We noted previously that in 2009 and in 2010, the impact of this transition on processing equipment was most obvious in equipment used with traditional aluminum interconnects. For example, the high-density plasma CVD sector (HDPCVD), which is used for depositing undoped (USG) and doped (PSG and FSG) films saw revenues drop 72% in 2009. In 2010, HDPCVD grew only19.4%!

| |

Overall Equipment

|

Copper Equipment

|

| 2009 |

-39%

|

-9%

|

| 2010 |

+105%

|

+152%

|

The integration of copper into memory devices presents a different set of challenges than the long-established logic processes. DRAM and Flash, which comprise the majority of the memory applications, exhibit high aspect ratios, small CD sizes, and critical sensitivity to line resistance.

In 2009 we saw the implementation of copper into memory devices. In 2010, growth in logic was more pronounced than memory. The key here is that in a logic device there are 10-12 layers of copper interconnects versus only 1 layer for memory. So 2010 was an exceptional year for copper because it combined the robust growth of logic as well as the continued transition to copper for memory.

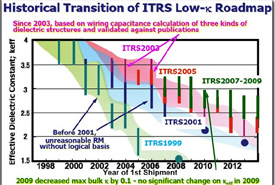

A key to the benefits of copper includes low-k inter-level dielectrics. The problem is that there have been too many technological problems to overcome, and the ITRS kept pushing out the introduction of low-k in its roadmap, as shown in the figure.

Critical to low-k films are the chemical precursors used for PECVD deposition, and the top ultra-low-k precursors, with a value approaching $100 million in the next few years are:

- Tetramethyl silane (4MS)

- Trimethyl silane (3MS)

- Octamethylcyclotetrasiloxane (OMCTS)

- Tetraoxymethylcyclotetrasiloxane (TOMCTS)

- Dimethyl-dimethoxy-silane (DMDMOS)

- Porous diethoxymethylsilane (PDEMS)

Silicon Tetrafluoride (SiF4) is another precursor but not viewed in the industry as a viable low-k material because the dielectric constant of the films is at or above 2.7.

Air Products is the key supplier of these low-k precursors, as it is a supplier of for all three major CVD processes: Black Diamond, Coral, and Aurora. Other firms include Dow Electronic Materials, JSR Micro, ATMI, and Honeywell